Lithium battery electrolyte and application thereof in lithium ion battery

An electrolyte, lithium battery technology, applied in electrolyte, secondary battery, secondary battery repair/maintenance, etc., can solve the negative impact of increasing battery internal resistance, battery rate performance and low temperature performance, and the effect is not as good as fluorinated solvent electrolysis It can solve the problems of high temperature gas production, improve the stability of high voltage cycle, and broaden the environmental adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of lithium battery electrolyte

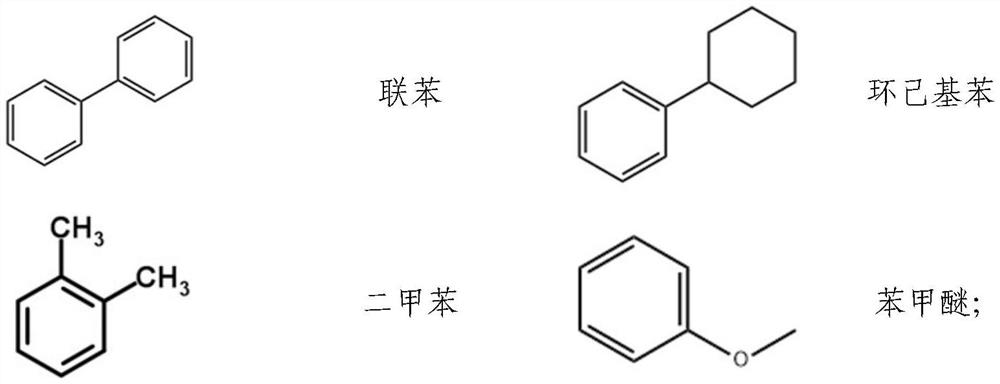

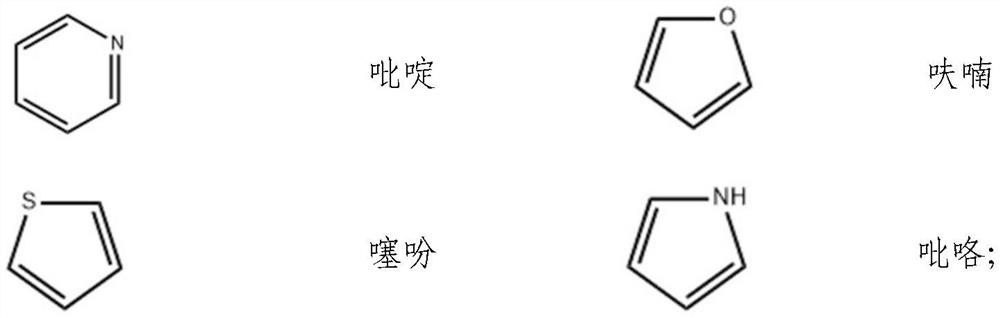

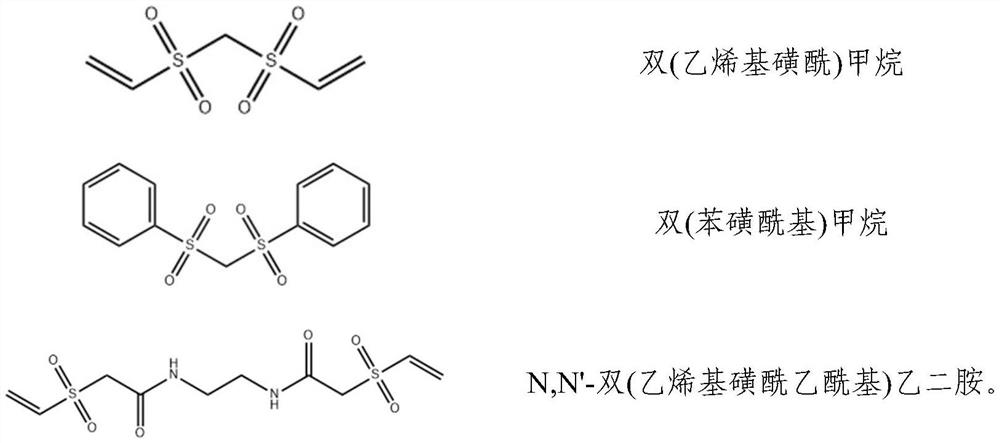

[0043] The preparation of the electrolyte in the examples is carried out in an argon glove box, and the moisture and oxygen content in the glove box are all controlled below 0.5ppm. Lithium hexafluorophosphate of ethyl ester and 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether (EMC:FEC:TFEA:F-EPE=50:25:15:10) (concentration 1.0M) and lithium difluorooxalate borate (0.1M) solution, adding mass ratios were 0.5% lithium difluorophosphate, 1% 1,3-propane sultone, 0.5% 1,3-(1 -propene) sultone, 0.5% adiponitrile, 0.1% 2-fluorobiphenyl and 0.5% bis(vinylsulfonyl)methane to make lithium battery electrolyte. After testing, the water in the electrolyte is <20ppm, and the free acid is <50ppm.

[0044] 2. Preparation of lithium ion battery

[0045] In the embodiment, a 2Ah battery is used, the lithium-rich pole piece is used as the positive electrode, the silicon-carbon pole piece is used as the negative pole, and the poly...

Embodiment 2

[0047] 1. Preparation of lithium battery electrolyte

[0048] The preparation of electrolyte in the embodiment is carried out in an argon glove box, and the moisture and oxygen content in the glove box are all controlled below 0.5ppm. (EMC: FEC: DFEA = 50: 25: 25) Lithium hexafluorophosphate (concentration 1.0M) and lithium bisfluorosulfonyl imide (0.1M) solution, add mass ratio of 0.5% lithium difluorophosphate, 1% 1 ,3-propane sultone, 0.5% 1,3-(1-propene) sultone, 0.5% adiponitrile, 0.2% cyclohexylbenzene and 0.5% N,N'-bis(vinylsulfonyl acetyl base) ethylenediamine to make lithium battery electrolyte. After testing, the water in the electrolyte is <20ppm, and the free acid is <50ppm.

[0049] 2. Preparation of lithium ion battery

[0050] In the embodiment, a 2Ah battery is used, the lithium-rich pole piece is used as the positive electrode, the silicon-carbon pole piece is used as the negative pole, and the polyolefin diaphragm and the lithium battery electrolyte prepar...

Embodiment 3

[0052] 1. Preparation of lithium battery electrolyte

[0053] The preparation of electrolyte in the embodiment is carried out in an argon glove box, and the moisture and oxygen content in the glove box are all controlled below 0.5ppm, to methyl ethyl carbonate, fluoroethylene carbonate and 2,2,2-trifluoroacetic acid In ethyl ester (EMC:FEC:TFEA=50:25:25) lithium hexafluorophosphate (1.0M), lithium difluorooxalate borate (0.5M) and lithium bisfluorosulfonyl imide (0.5M) solution, add mass ratio respectively 0.5% lithium difluorophosphate, 1% 1,3-propane sultone, 0.5% 1,3-(1-propene) sultone, 0.5% adiponitrile, 0.3% 2,5-dichlorothiophene and 0.8% bis(vinylsulfonyl)methane to make lithium battery electrolyte. After testing, the water in the electrolyte is <20ppm, and the free acid is <50ppm.

[0054] 2. Preparation of lithium ion battery

[0055] In the embodiment, a 2Ah battery is used, the lithium-rich pole piece is used as the positive electrode, the silicon-carbon pole pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com