Anticorrosion and preservation compound preparation and application thereof

A technology for preparations and meat products, applied in the application, oily food ingredients, preservation of meat/fish with chemicals, etc., can solve problems such as poor results, extend shelf life, reduce initial bacterial count, and application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

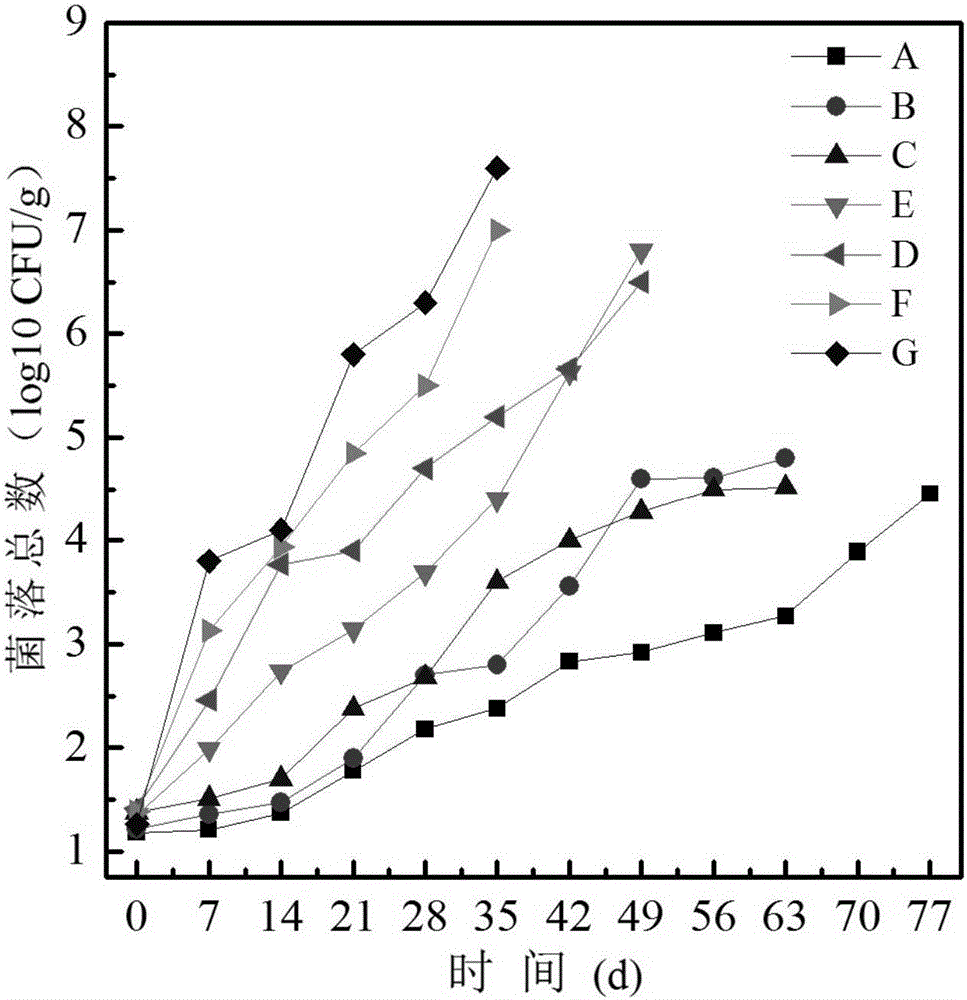

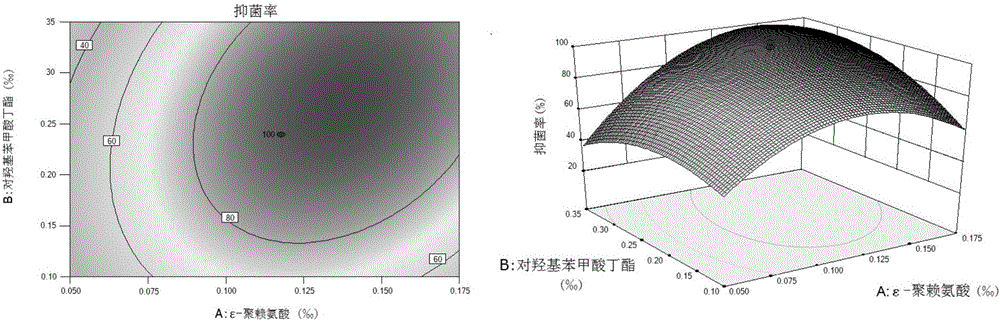

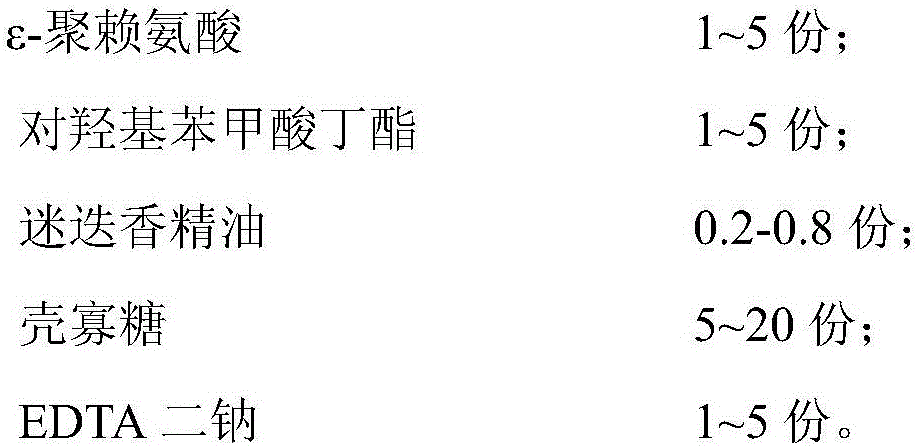

[0031] The mass concentration of ε-polylysine is 0.05‰~0.175‰ (factor A), butyl p-hydroxybenzoate is 0.1‰~0.35‰ (factor B), rosemary essential oil is 0.02‰~0.1‰, and chitosan oligosaccharide is 0.5‰ ~1.5‰, EDTA disodium 0.05‰~0.15‰ to do five-factor three-level experimental design, get the optimal ratio of the compound preparation and the interaction between factor A ε-polylysine and factor B butyl p-hydroxybenzoate synergy. See the results for details figure 2 .

Embodiment 2

[0032] Example 2: Application in smoked ham

[0033] Take 100g of ε-polylysine, 200g of butyl p-hydroxybenzoate, 60g of rosemary essential oil, 1000g of chitosan oligosaccharide, 150g of disodium EDTA, add 1000g of water and mix to obtain the compound preservative. Add the compound antistaling agent to the product according to 0.2% of the weight of the low-temperature meat product (mass without water), add it in the tumbling step, and tumbling with the product for 12 hours, then fill, dry, smoke and cook, cool and pack, and the finished product Refrigerate at 4°C. After treatment and packaging, the shelf life of the smoked ham can be extended by 20 days under low-temperature refrigeration, and the color and luster is good during storage, the aroma is unique, and its own flavor remains excellent.

Embodiment 3

[0034] Example 3: Application in smoked ham slices

[0035] Take ε-polylysine 100g, butyl p-hydroxybenzoate 250g, rosemary essential oil 70g, chitosan oligosaccharide 1000g, EDTA disodium 100g, add water 1000g and mix well to get this compound preservative, according to the weight of low-temperature meat products 0.1% of the product (mass without water) is added to the product, added in the tumbling step, and tumbling with the product for 12 hours, then filled, dried, smoked and cooked, cooled and sliced, packaged, and the finished product is refrigerated at 4°C. The shelf life of the smoked ham slices after treatment and packaging can be extended by 25 days under low-temperature refrigeration, and the color and luster is good during storage, the fragrance is unique, and its own flavor remains excellent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com