Desulfurizing tower inlet flue duct and system with desulfurized wastewater concentration function

A technology of desulfurization wastewater and inlet flue, which is applied in the direction of gaseous effluent wastewater treatment, water pollutants, water/sewage treatment, etc., can solve the problem of increasing water treatment investment, operating costs, wastewater treatment investment, high operating costs, Large flow and other issues, to achieve the effect of promoting heat transfer, simple structure, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

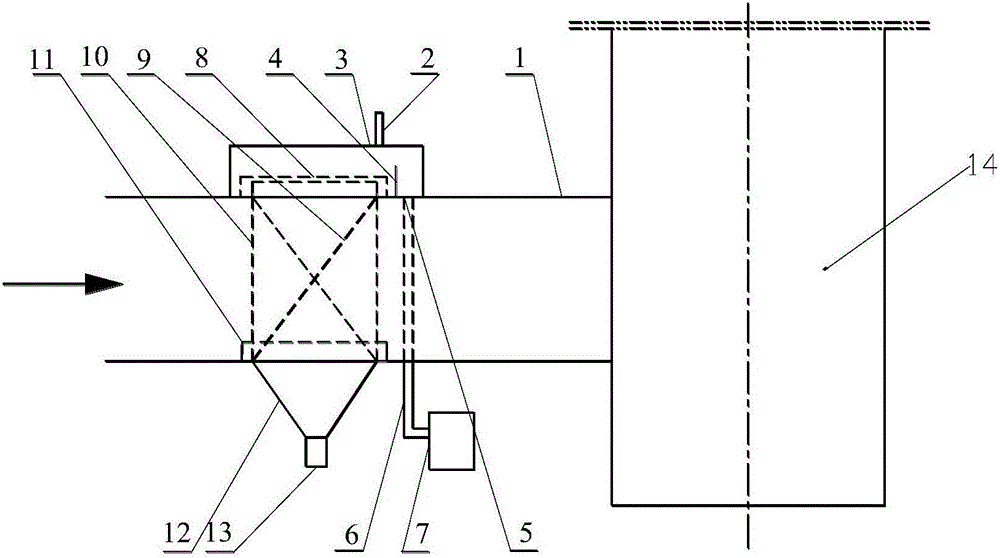

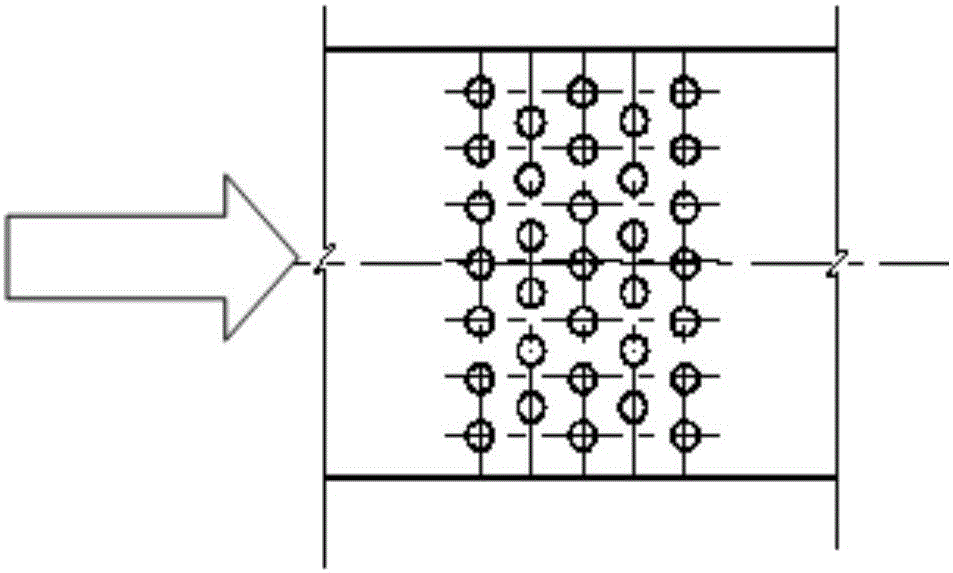

[0064] refer to figure 1 , Fig. 2(a) and Fig. 2(b), the liquid distribution element 10 is a round tube, the round tube is vertically arranged, and the round tubes are roughly parallel, the desulfurization waste water enters the water tank 3 from the water inlet 2, and the overflow weir 4 Under the action of the desulfurization wastewater, a certain water level is maintained on the upper part of the liquid distributor 8 of the water tank 3, so that a certain water pressure is maintained at the liquid distributor 8, and under the action of the water pressure, the desulfurization wastewater flows through the liquid distributor 8 to each On the top of a circular tube, the desulfurization wastewater flows continuously and from top to bottom through the outer surface of the circular tube, forming a continuous and uniform water film on the outer surface of the metal circular tube of the first liquid distribution element 10, and the flue gas flows through the circular tube. When the g...

Embodiment 2

[0067] refer to figure 1 , FIG. 3(a), FIG. 3(b) and FIG. 3(c), the liquid distribution element 10 is a groove structure, and the direction of the inner concave surface of the groove structure is opposite to the direction of the smoke flow. The liquid distribution element 10 with a groove structure is preferably a channel steel, and may also be similar in shape to a channel steel, but the material is different from the channel steel. A plurality of liquid distribution elements 10 are arranged in multiple rows, preferably 1-40 rows, and each row includes a plurality of liquid distribution elements 10 . The row spacing and column spacing between the centerlines of the liquid distribution element 10 are respectively more than twice the width of the channel steel.

[0068] The inclination direction of the liquid distribution element 10 is the same as the flow direction of the smoke, and the angle between it and the horizontal direction is preferably 45-80°.

[0069] The desulfuri...

Embodiment 3

[0071] refer to figure 1 , Fig. 4(a) and Fig. 4(b), the liquid distribution element 10 is a flat plate type, and the flat liquid distribution element is generally arranged parallel to the flow direction of the flue gas, and can be a metal plate, and the metal plate is arranged in a vertical direction. The distance between two adjacent metal plates is 100-1000mm.

[0072] The desulfurization wastewater enters the water tank 3 from the water inlet 2. Under the action of the overflow weir 4, the desulfurization wastewater maintains a certain water level on the upper part of the liquid distributor 8 of the water tank 3, so that a certain water pressure is maintained at the liquid distributor 8. Under the action of water pressure, the desulfurization wastewater flows through the liquid distributor 8 to the top of each liquid distribution element 10 shown in Figure 4, and the desulfurization wastewater flows through the liquid distribution element 10 continuously and from top to bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com