Preparation method of TiO2/active carbon net-loaded adsorption- photocatalysis water purifying composite material

A composite material and activated carbon technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of difficult recovery of powder suspension phase catalyst, poor treatment effect of organic pollution, secondary pollution and other problems, to achieve the effect of easy separation, difficult recycling, and accelerated separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

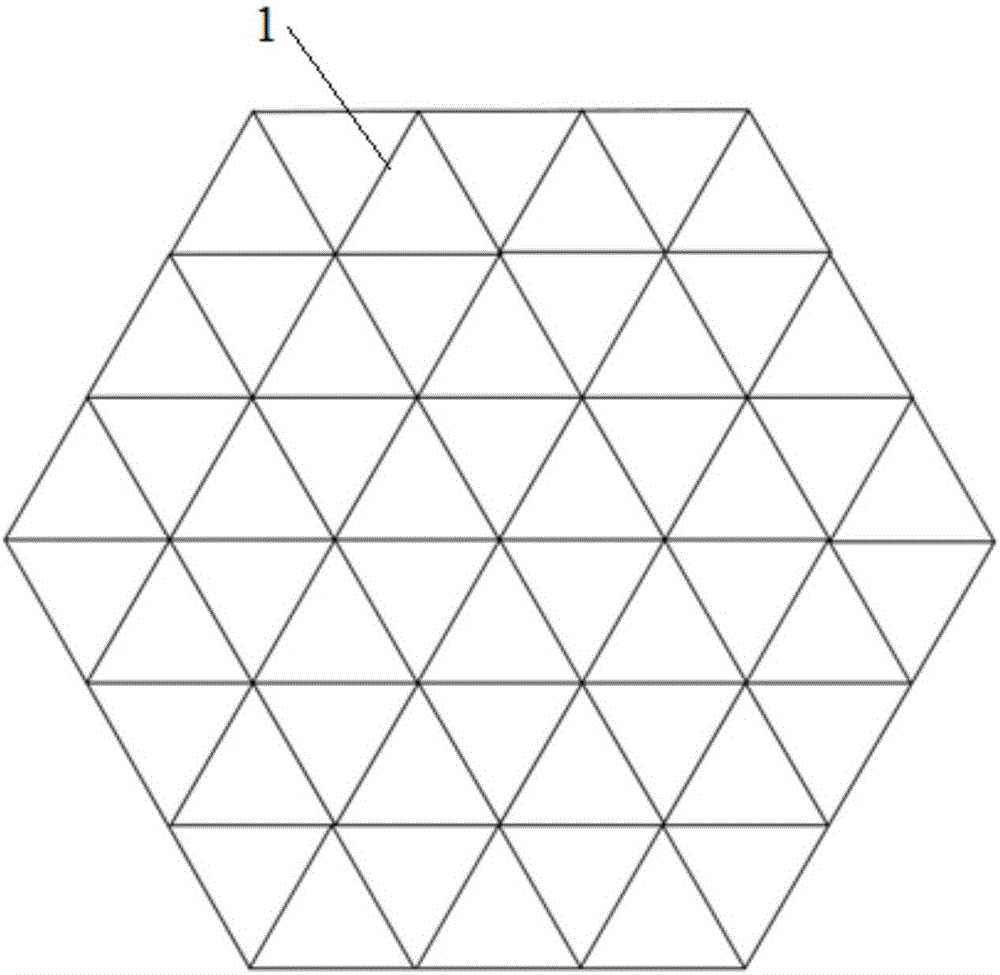

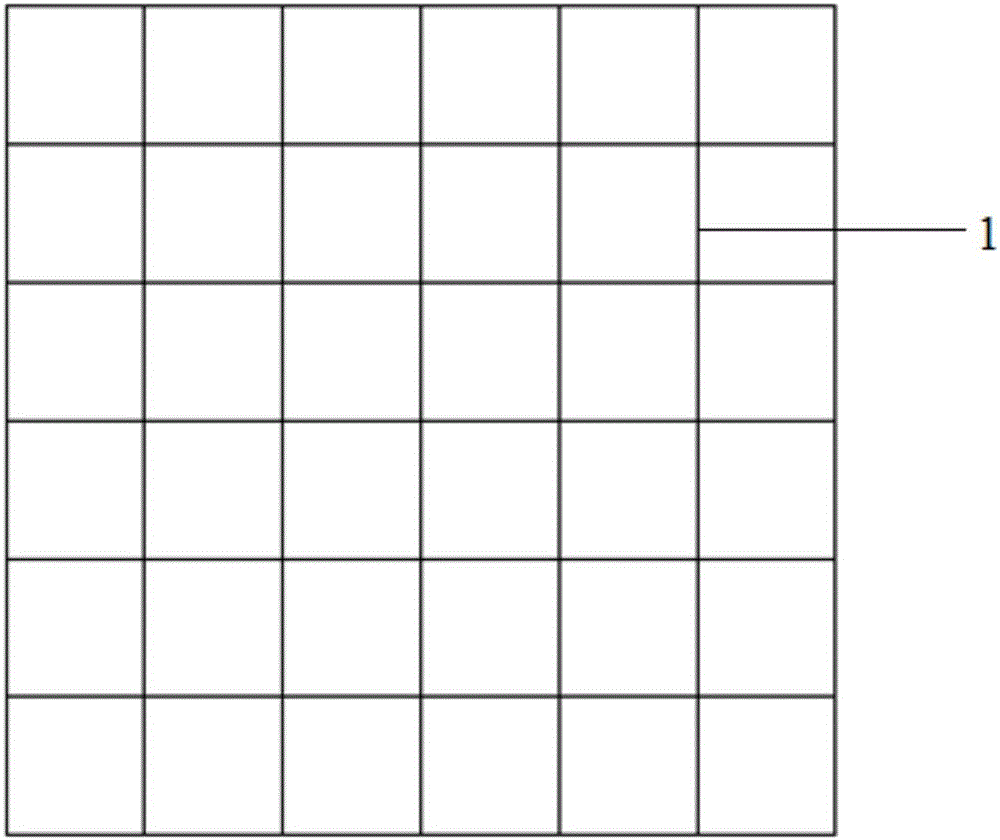

[0029] Specific implementation mode 1: This implementation mode is a network-borne TiO 2 The preparation method of the adsorption-photocatalytic water purification composite material of activated carbon, specifically is carried out according to the following steps:

[0030] 1. Activated carbon pretreatment: Granular activated carbon and HNO with a volume fraction of 17% 3 The aqueous solution is uniformly mixed, then heated and stirred with a magnetic stirrer at a temperature of 100°C for 1h to 3h, then filtered and washed with distilled water for 6 to 7 times, and dried in a hot air dryer at a temperature of 80°C for 2h to obtain the prepared The activated carbon that has been processed; the mass and volume fraction of the granular activated carbon is 17% HNO 3 The volume ratio of the aqueous solution is 1g:(35mL~45mL);

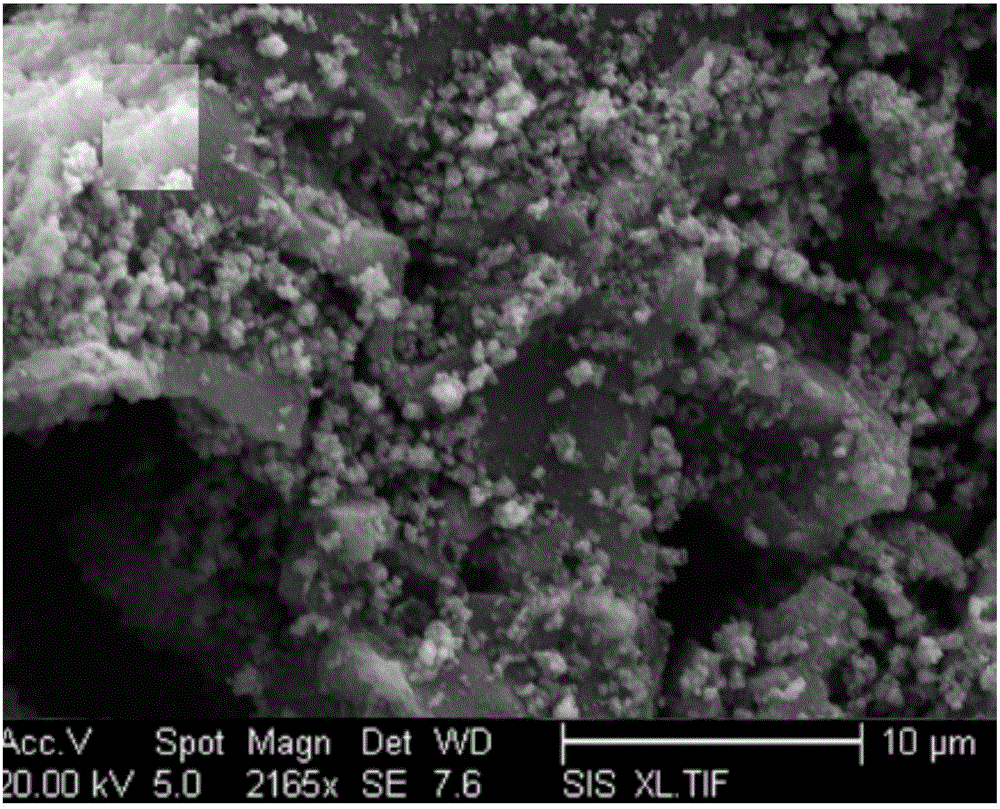

[0031] 2. TiO 2 / Activated carbon composite powder preparation: add the activated carbon pretreated in step 1 to P25 type TiO 2 In the aqueous solution...

specific Embodiment approach 2

[0033] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass and volume fraction of the granular activated carbon described in step one are 17% HNO 3 The volume ratio of the aqueous solution is 1g:41.7mL. Others are the same as the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the P25 type TiO described in step two 2 P25 type TiO in aqueous solution 2The concentration is 500mg / L. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com