Catalyst for synthesizing vinyl acetate with acetylene process, preparation method and vinyl acetate synthesizing method

A vinyl acetate and catalyst technology, applied in the field of vinyl acetate synthesis, acetylene process vinyl acetate catalyst, and preparation, can solve the problems of low production capacity, rapid activity decline, short service life, etc., and achieve the effect of improving catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention proposes a kind of preparation method of acetylene method vinyl acetate catalyst, introduces at least one V group non-metallic element on activated carbon carrier; It comprises the following steps:

[0021] 1) Stirring and mixing with activated carbon in an aqueous solution, the aqueous solution containing at least one compound of Group V non-metallic elements;

[0022] 2) Suction filtering, drying and calcining the activated carbon to obtain a doped activated carbon carrier;

[0023] 3) loading acetate by equal volume impregnation method to obtain acetylene method vinyl acetate catalyst;

[0024] Wherein, the mass ratio of the compound of the group V non-metal element, activated carbon, and acetate is 0.1-0.4:1:0.1-0.3.

[0025] A kind of vinyl acetate synthesis method that the present invention proposes, in the presence of above-mentioned acetylene method vinyl acetate catalyst, raw material gas composition is acetylene in molar ratio: acetic ac...

Embodiment 1

[0027] Catalyst preparation method:

[0028] 1) Add 0.2 g of cyanamide solution with a mass fraction of 50% to 5 g of distilled water for dilution, add 1 g of coconut shell activated carbon, and fully mix and stir at room temperature for 24 hours;

[0029] 2) Suction-filtering the activated carbon, drying at 50°C for 12 hours, and fully calcining at 400°C for 1 hour to obtain a nitrogen-doped activated carbon carrier;

[0030] 3) Loading 0.1 g of zinc acetate by an equal-volume impregnation method to obtain an acetylene-method vinyl acetate catalyst.

[0031] The comparative example is a zinc acetate / activated carbon catalyst, the carrier is not doped with nitrogen, and other reaction conditions are the same.

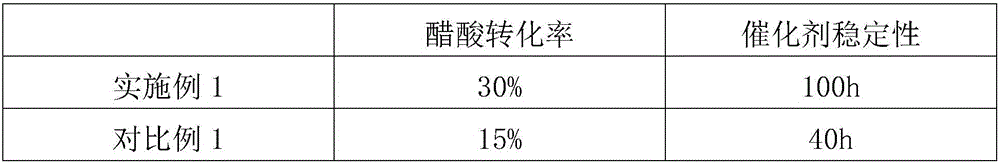

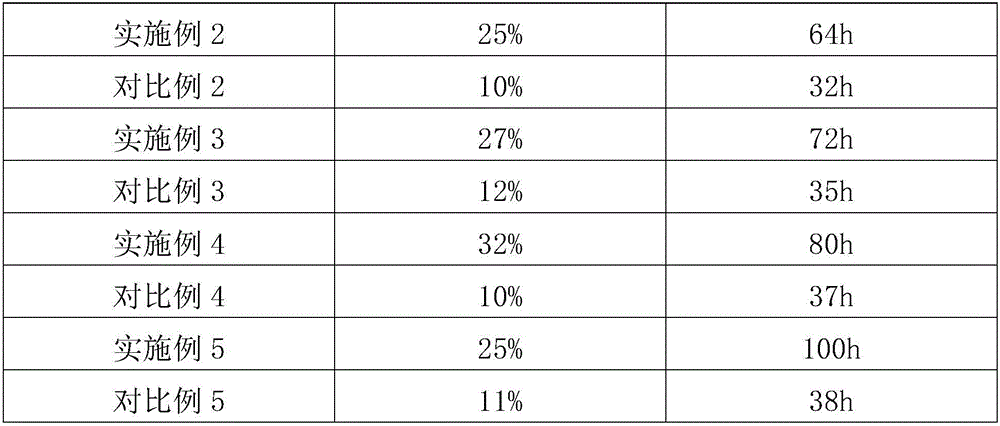

[0032] Catalyst evaluation:

[0033] Catalysts synthesized by the above method were evaluated using a gas-solid phase catalytic reaction device. The evaluation conditions are: catalyst loading: 5ml catalyst; reaction temperature: 180°C; raw material volume space velo...

Embodiment 2

[0036] Catalyst preparation method:

[0037] 1) Add 0.8 g of melamine solution with a mass fraction of 50% to 5 g of distilled water for dilution, add 1 g of coal-based activated carbon, and fully mix and stir at room temperature for 12 hours;

[0038] 2) Suction-filtering the activated carbon, drying at 100°C for 6h, and fully calcining at 900°C for 0.5h to obtain a nitrogen-doped activated carbon carrier;

[0039] 3) Loading 0.3 g of potassium acetate by an equal-volume impregnation method to obtain an acetylene-method vinyl acetate catalyst.

[0040] The comparison example is potassium acetate / activated carbon catalyst, the carrier is not doped with nitrogen, and other reaction conditions are the same.

[0041] Catalyst evaluation:

[0042] Catalysts synthesized by the above method were evaluated using a gas-solid phase catalytic reaction device. The evaluation conditions are: catalyst loading: 5ml catalyst; reaction temperature: 150°C; raw material volume space velocity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com