Preparation method of protein type cement foaming agent and concrete containing the same

A technology of cement foaming agent and protein, which is applied in the field of preparation of protein-based cement foaming agent, can solve problems such as pollution of leather chips, and achieve the effects of solving high cost, high foam stability and improving compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Preparation example of protein type cement foaming agent.

[0032] Add 40g of dried leather shavings, 320ml of tap water, 3.2g of calcium hydroxide, and 8g of sodium dihydroxynaphthalene-6-sulfonate into a three-necked flask, stir and hydrolyze at 80°C, and reflux for 10h. After the hydrolysis is completed, the gauze is sucked and centrifuged to obtain a hydrolyzed solution and a hydrolyzed residue of chromium-containing leather scraps.

[0033] Take 300ml of the hydrolyzate and add it to the beaker, keep the pH of the solution at this time between 6.5-7.5 by adding acid, and add 0.3g of preservative sodium azide. Add 0.36g sodium lauryl sulfate, 0.36g sodium lauryl alcohol ether sulfate, 0.36g hydroxyethyl cellulose and methyl triethoxysilane 0.1g successively to the hydrolyzate, mix well to obtain hair Foam agent mother liquor.

Embodiment 2

[0034] Embodiment 2: Preparation example 1 of foam concrete.

[0035] Preparation steps: Add cement, tap water, bentonite and air-entraining water reducer to the protein-type cement foaming agent prepared in Example 1; stir to form a uniform slurry, pour the slurry into a mold for curing, and obtain concrete. The formula is shown in Table 1. The properties of foamed concrete were determined by taking absolute dry density, water absorption and compressive strength as the investigation indexes.

[0036] Table 1 foam concrete formula

[0037]

Embodiment 3

[0038] Embodiment 3: Preparation example 2 of foam concrete.

[0039] Add cement, tap water, chromium-containing leather shavings hydrolysis residue, bentonite and air-entraining water reducer to the protein-type cement foaming agent prepared in Example 1, stir to form a uniform slurry, pour the slurry into a mold for curing, and obtain concrete . The formula is shown in Table 2.

[0040] Table 2 foam concrete formula

[0041]

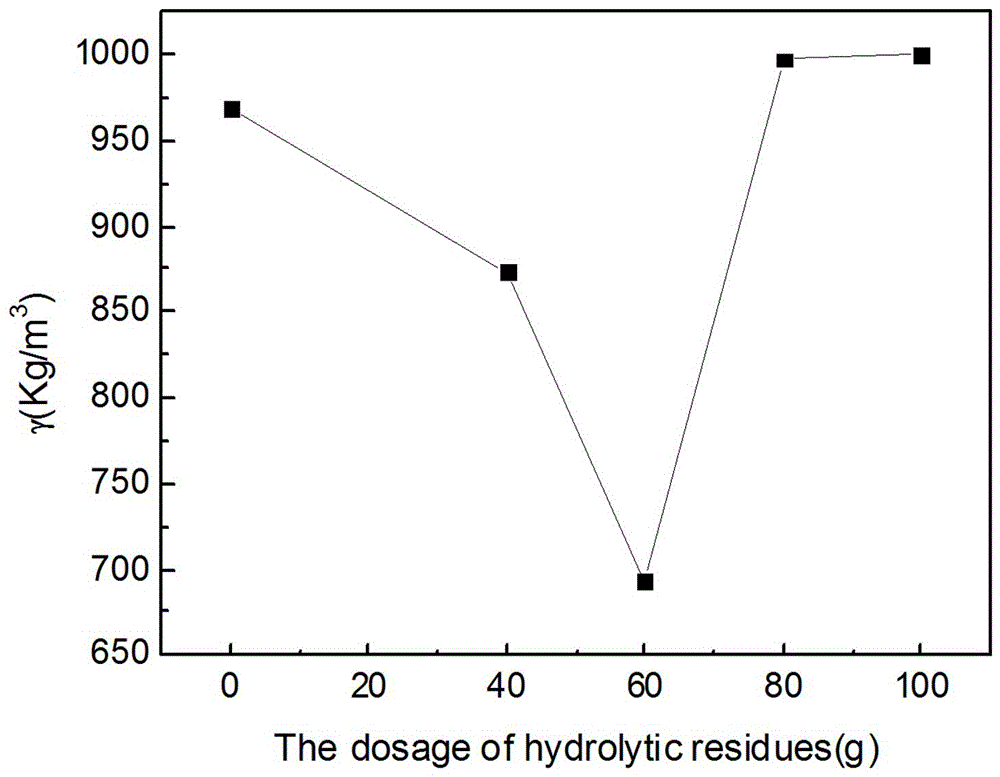

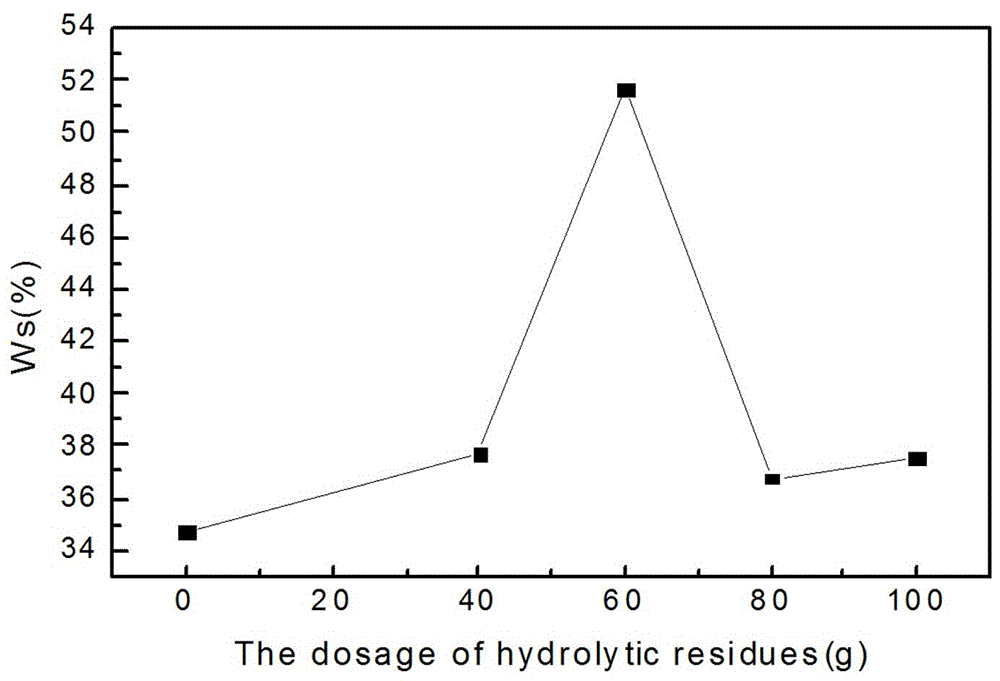

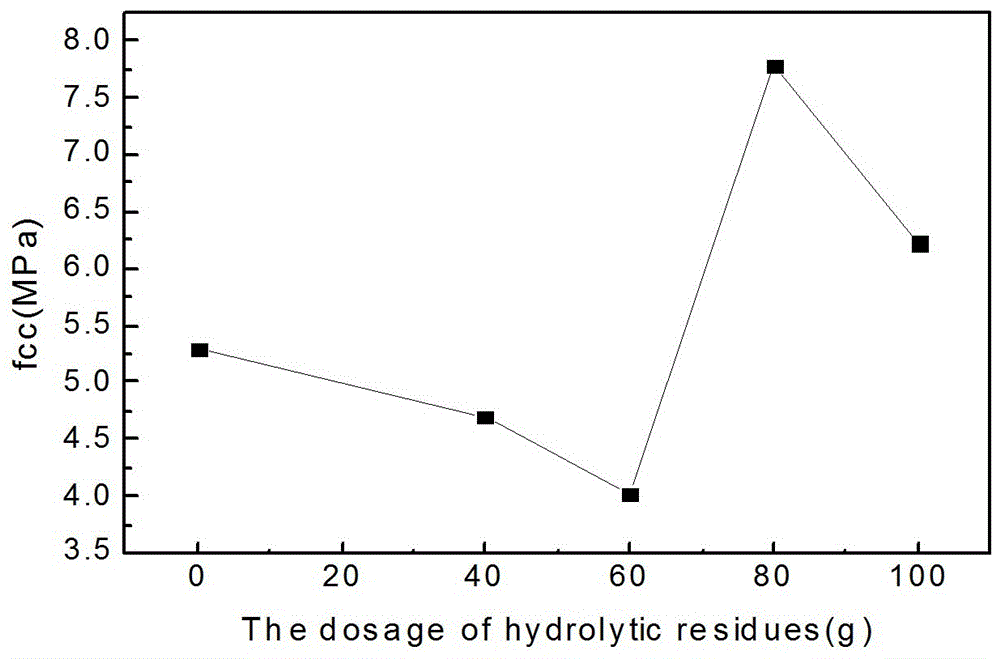

[0042] The amount of chromium-containing leather shavings hydrolyzed residue was adjusted within the range of 20-100g to prepare foamed concrete, and the properties of the foamed concrete were measured with absolute dry density, water absorption and compressive strength as the investigation indexes.

[0043] The following is the performance test of foam concrete:

[0044] (1) Determination of the absolute dry density of foam concrete.

[0045] According to the "JCT 2125-2012 Foam Concrete for Roof Thermal Insulation" standard of the building mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com