Electrolysis method for producing high-purity hydrogen peroxide and hydrogen with low cost

A technology of pure hydrogen peroxide and electrolysis method, which is applied in the field of preparing high-purity hydrogen peroxide and hydrogen by electrolysis, which can solve the problems of large power consumption, high cost of power-consuming electrode materials, and high production cost, and achieve power utilization efficiency High, improve the efficiency of electric energy utilization, reduce the effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

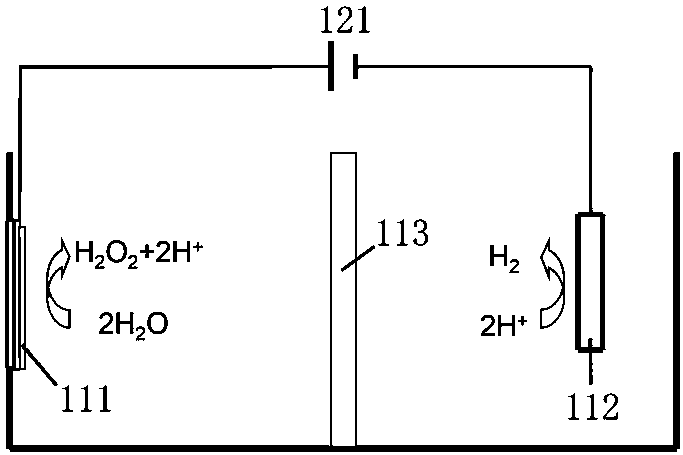

[0018] The method for producing high-purity hydrogen peroxide and hydrogen of the present invention adopts a pure-phase or doped bismuth vanadate single wafer with a crystal orientation of {111}, {110}, {100} or {010} as an anode of an electrolytic cell. The specific crystal planes of the pure phase or doped bismuth vanadate single crystal, such as {111}, {110}, {100}, {010}, can be realized on these crystal planes under the action of 2.1-2.8 V applied bias voltage Direct oxidation of water to generate H 2 o 2 , the reaction formula is 2H 2 O + 2h + = H 2 o 2 + 2H + , does not require such as SO 4 2- Plasma participation. However, other surfaces such as {001}, {101}, and {011} do not have the above characteristics, that is, under the condition of external bias, they can only selectively oxidize water to form O 2 , but cannot generate H 2 o 2 . Therefore, the present invention selects {111}, {110}, {100}, {010} as selective precipitation H 2 o 2 The active surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com