Color fixing agent for reactive dyeing and preparation method of color fixing agent

A technology of reactive dyes and color-fixing agents, applied in dyeing, textiles, and papermaking, can solve the problems of easy hydrolysis of chemical bonds, high formaldehyde content, and harm to human health, achieve broad market prospects, reduce formaldehyde content, and reduce affinity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of preparation method of the aldehyde-free color-fixing agent for reactive dyes of the present invention is realized through the following steps:

[0025] (1) Add the imidazolium chloride salt monomer, trifluoroethyl acrylate, dihydroxyethyl diallyl ammonium chloride, acid regulator, After deionized water, turn on reflux to condense, stir, and start heating;

[0026] (2) When the temperature rises to 85~100 DEG C, then start to drip the initiator solution whose mass percentage concentration is 1~10%, this initiator solution is prepared by the described initiator and part of the deionized water; The adding time is controlled at 0.5-3 hours, and the temperature is controlled at 85-100°C during the dropwise addition;

[0027] (3) After the addition, keep the temperature and react for 1 to 5 hours, then add the remaining water, stir for 0.5 hours, and discharge the material to obtain the color-fixing agent.

Embodiment 1

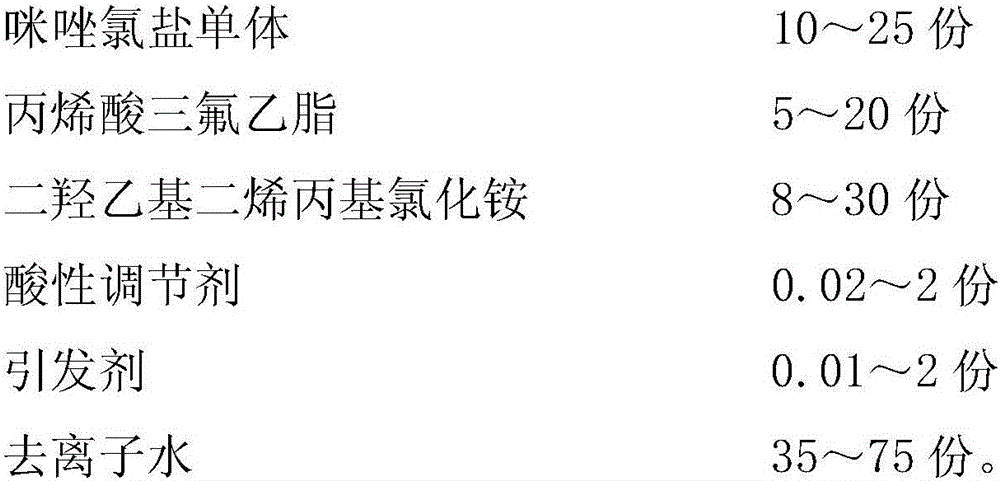

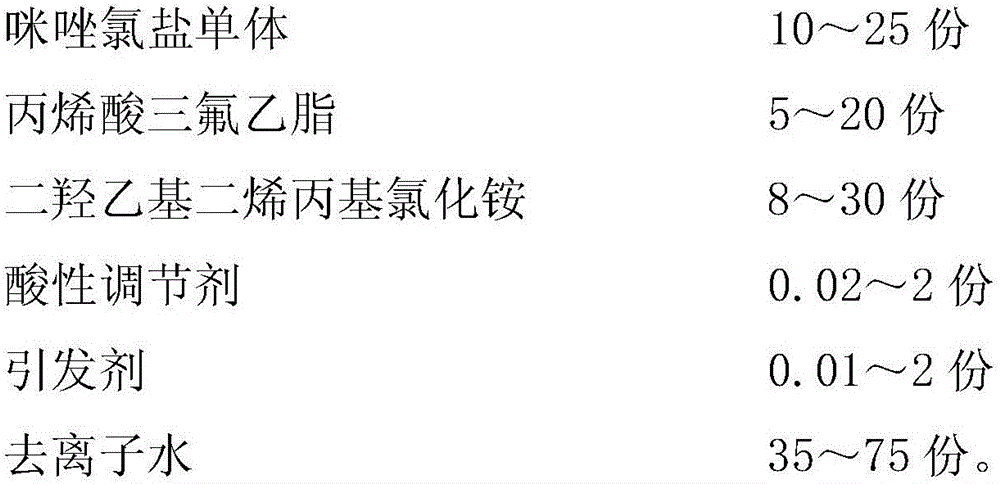

[0030] A kind of color-fixing agent for dyeing with reactive dyes of the present invention is made of the following raw material components in parts by weight:

[0031]

[0032] Its preparation method is realized through the following steps:

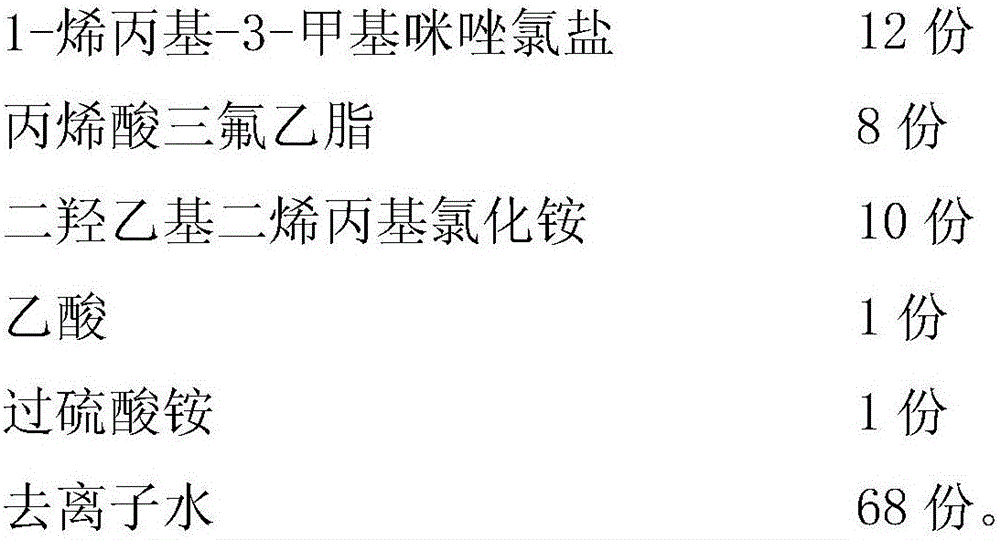

[0033] (1) Add 12 parts of 1-allyl-3-methylimidazolium chloride salt, 8 parts of trifluoroethyl acrylate, 10 parts of dihydroxyethyl After diallyl ammonium chloride, 1 part of acetic acid, and 10 parts of deionized water, turn on reflux to condense, stir, and start to heat up;

[0034] (2) When the temperature rises to 88°C, then start to drip the ammonium persulfate solution with a mass percent concentration of 2%, which is prepared from 1 part of ammonium persulfate and 49 parts of deionized water; the time for adding Control it within 1 hour, and control the temperature at 90°C during the dropwise addition;

[0035] (3) After adding, heat-retain and react for 3 hours, then add the remaining water, stir for 0.5 hours, and then dis...

Embodiment 2

[0037] A kind of color-fixing agent for dyeing with reactive dyes of the present invention is made of the following raw material components in parts by weight:

[0038]

[0039] Its preparation method is realized through the following steps:

[0040] (1) Add 15 parts of 1-allyl-3-ethylimidazolium chloride, 10 parts of trifluoroethyl acrylate, 12 parts of dihydroxyethyl After diallyl ammonium chloride, 0.5 parts of tartaric acid, and 15 parts of deionized water, turn on reflux to condense, stir, and start to heat up;

[0041] (2) When the temperature rises to 92°C, then start to drip the sodium persulfate solution with a mass percentage concentration of 4%, which is prepared from 0.5 parts of sodium persulfate and 12 parts of deionized water; the time for adding Control it within 1.5 hours, and control the temperature at 95°C during the dropwise addition;

[0042] (3) After adding, heat-retain and react for 2.5 hours, then add the remaining water, stir for 0.5 hours, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com