Method for recycling rare earth extraction residual wastewater with high sodium salt content

A waste water, high sodium technology, applied in metallurgical waste water treatment, chemical instruments and methods, heating water/sewage treatment, etc., to achieve the effects of low cost, good social benefits, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

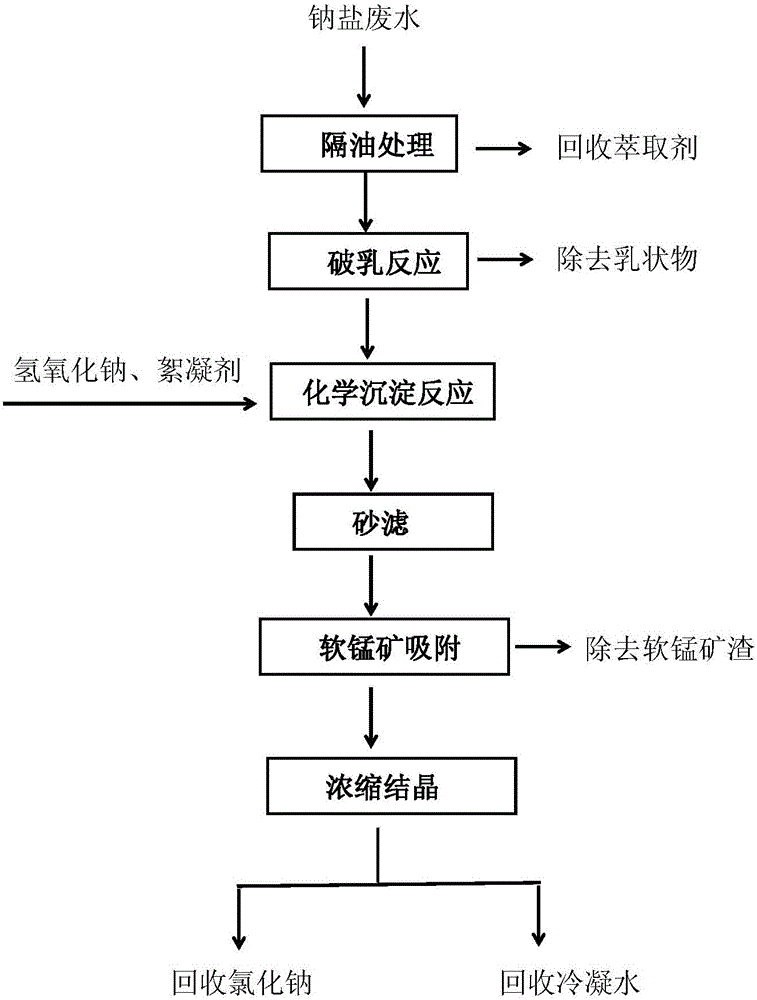

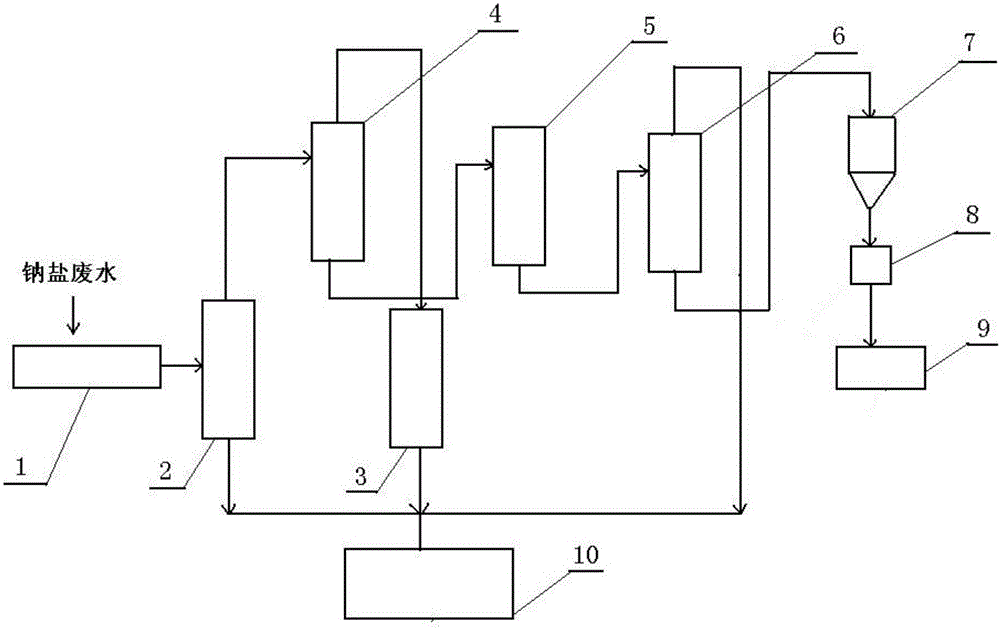

Method used

Image

Examples

Embodiment 1

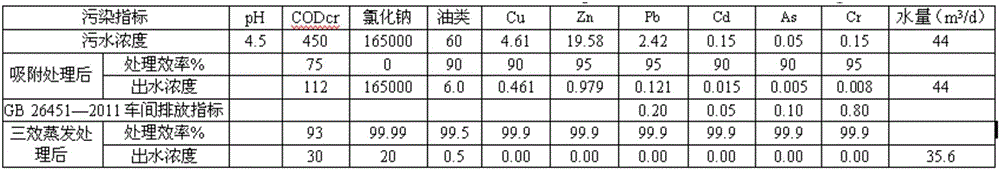

[0031] The sodium salt wastewater discharged from the production process of a company's rare earth separation project was used as the raw water in this embodiment.

[0032] A method for recovering rare earth raffinate high-sodium salt wastewater, comprising the following steps:

[0033] (1) Oil separation: discharge the rare earth raffinate high-sodium salt wastewater into the grease trap, and after standing for 3 hours to separate layers, recover the P507 extractant to obtain crude sodium-salt wastewater;

[0034] (2) Demulsification reaction: the thick sodium salt wastewater obtained in step (1) is passed through a demulsification reaction bed, and SP-169 demulsifier is added to carry out a demulsification reaction, and the emulsion is removed to obtain degreasing sodium salt wastewater;

[0035] (3) Chemical precipitation reaction: add a sodium hydroxide solution with a concentration of 1mol / L to the deoiled sodium salt wastewater, adjust the pH to 8.5, and then add polyacr...

Embodiment 2

[0043] The sodium salt wastewater discharged from the production process of a company's rare earth separation project was used as the raw water in this embodiment.

[0044] A method for recovering rare earth raffinate high-sodium salt wastewater, comprising the following steps:

[0045] (1) Oil separation: discharge the rare earth raffinate high-sodium salt wastewater into the grease trap, and after standing for 2.5 hours to separate layers, recover the P507 extractant to obtain crude sodium-salt wastewater;

[0046] (2) Demulsification reaction: the thick sodium salt wastewater obtained in step (1) is passed through a demulsification reaction bed, and AP-221 demulsifier is added to carry out a demulsification reaction, and the emulsion is removed to obtain degreasing sodium salt wastewater;

[0047](3) Chemical precipitation reaction: add sodium hydroxide solution with a concentration of 2 mol / L to the deoiled sodium salt wastewater, adjust the pH to 9, and then add sodium li...

Embodiment 3

[0055] The sodium salt wastewater discharged from the production process of a company's rare earth separation project was used as the raw water in this embodiment.

[0056] A method for recovering rare earth raffinate high-sodium salt wastewater, comprising the following steps:

[0057] (1) Oil separation: discharge the rare earth raffinate high-sodium salt wastewater into the grease trap, and after standing for 2 hours to separate layers, recover the P507 extractant to obtain crude sodium-salt wastewater;

[0058] (2) Demulsification reaction: the thick sodium salt wastewater obtained in step (1) is passed through the demulsification reaction bed, and AE-169 demulsifier is added to carry out the demulsification reaction, and the emulsion is removed to obtain deoiled sodium salt wastewater;

[0059] (3) Chemical precipitation reaction: add sodium hydroxide solution with a concentration of 1.5mol / L to the deoiled sodium salt wastewater, adjust the pH to 8.5, and then add sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com