Double-circulation nitrogen and phosphorus removal wastewater treatment system and process

A wastewater treatment system and technology for denitrification and dephosphorization, applied in the field of water treatment, can solve the problems of low denitrification and dephosphorization efficiency, insufficient utilization of carbon sources, large dosage of dephosphorization agents, etc., and achieves low cost and improved effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

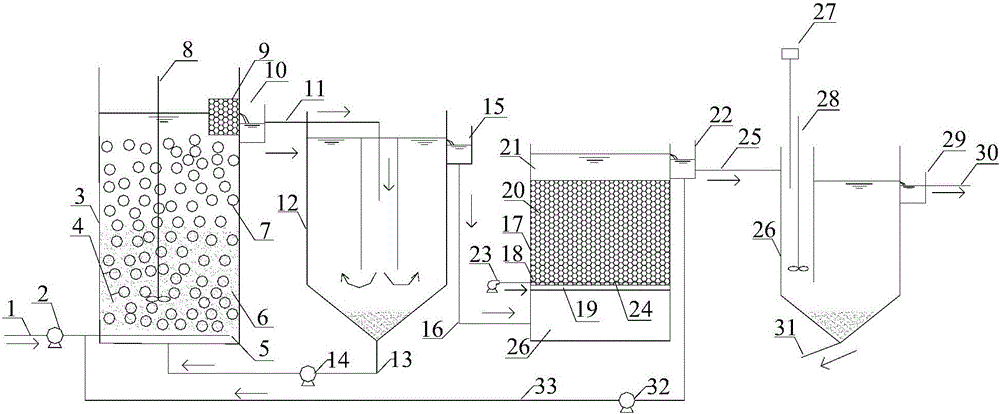

Embodiment 1

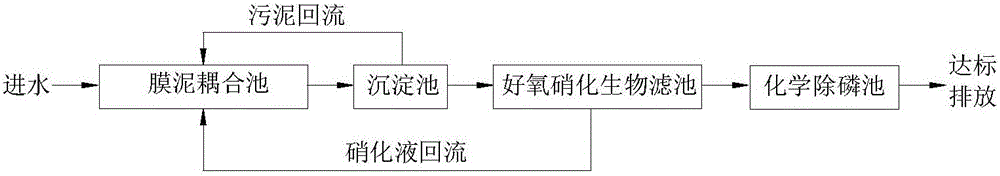

[0025] A domestic sewage treatment plant with a treatment capacity of 10,000 m 3 / d, influent COD concentration is 240mg / L, TP 12mg / L, NH 3 -N (ammonia nitrogen) concentration is 42mg / L, TN (total nitrogen) is 60mg / L, and suspended solids (SS) is 135mg / L. Sewage is treated sequentially through a flow-type membrane mud coupling tank, a sedimentation tank, an aerobic nitrification biological filter, and a chemical phosphorus removal tank. The hydraulic retention time of the flowing membrane-slime coupling tank is 2 hours, the reflux ratio of nitrification liquid is 130%, and the sludge reflux ratio is 50%; the dissolved oxygen of the aerobic nitrification biological filter is 4.0 mg / L, and the hydraulic retention time is 3 hours. The final effluent meets the first-class A discharge standard in the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

Embodiment 2

[0027] A chemical wastewater treatment plant with a treatment capacity of 3,000 m 3 / d, influent COD concentration is 2240mg / L, TP 42mg / L, NH 3 -N (ammonia nitrogen) concentration is 90mg / L, TN (total nitrogen) is 600mg / L, and suspended solids (SS) is 635mg / L. Sewage is treated sequentially through a flow-type membrane mud coupling tank, a sedimentation tank, an aerobic nitrification biological filter, and a chemical phosphorus removal tank. The hydraulic retention time of the mobile membrane-slime coupling tank is 12h, the reflux ratio of nitrification liquid is 280%, and the sludge reflux ratio is 80%; the dissolved oxygen of the aerobic nitrification biological filter is 5.0mg / L, and the hydraulic retention time is 12h. Final effluent COD concentration is 110mg / L, TP 0.03mg / L, NH 3 -N (ammonia nitrogen) concentration is 3mg / L, TN (total nitrogen) is 58mg / L, and suspended solids (SS) is 11mg / L.

Embodiment 3

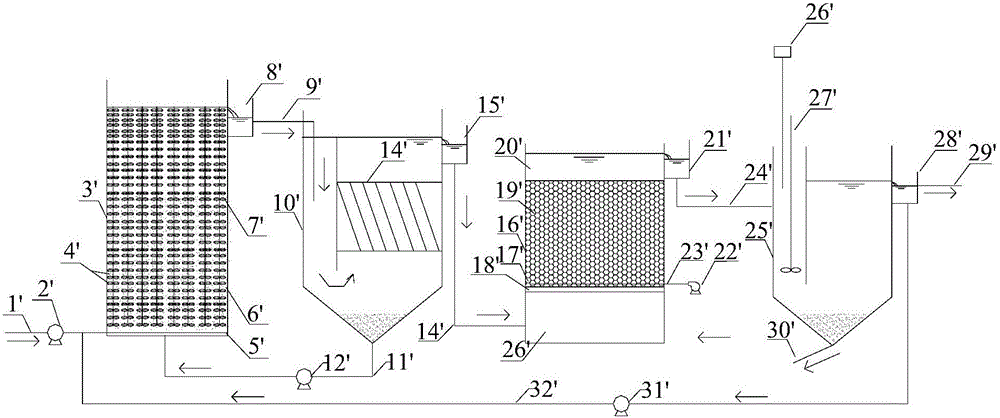

[0029] A domestic sewage treatment plant with a treatment capacity of 10,000 m 3 / d, influent COD concentration is 220mg / L, TP 11mg / L, NH 3-N (ammonia nitrogen) concentration is 46mg / L, TN (total nitrogen) is 65mg / L, and suspended solids (SS) is 115mg / L. Sewage is treated sequentially through a fixed membrane-mud coupling pond, a sedimentation pond, an aerobic nitrification biological filter, and a chemical phosphorus removal pond. The hydraulic retention time of the fixed membrane-mud coupling pool is 1h, the reflux ratio of nitrification liquid is 150%, and the sludge reflux ratio is 70%; the dissolved oxygen of the aerobic nitrification biological filter is 5.0mg / L, and the hydraulic retention time is 2h. The final effluent meets the first-class A discharge standard in the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com