Lithium-iron-doped nickel oxide negative temperature coefficient (NTC) thermistor material

A technology of negative temperature coefficient and thermistor, applied in the direction of resistors with negative temperature coefficient, resistors, non-adjustable metal resistors, etc., can solve the problems of structural relaxation, material aging, poor product consistency, etc., and achieve material The composition is simple, the sintering temperature is low, and the performance is stable and high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] According to the molecular formula Ni in this embodiment 1-x-y Li x Fe y O is batching, where x=0.04 and y=0. The initial raw material is selected from basic nickel carbonate NiCO 3 ·2Ni(OH) 2 ·4H 2 O, lithium carbonate Li 2 CO 3 . The material preparation is carried out according to the following experimental process steps:

[0020] (1) Press Ni 0.96 Li 0.04 O formula ingredients, weigh NiCO 3 ·2Ni(OH) 2 ·4H 2 O 24.0787g, Li 2 CO 3 0.2956g;

[0021] (2) Dissolve the raw materials weighed in the previous step in dilute nitric acid;

[0022] (3) Use a magnetic stirring heater to stir and mix the solution prepared in the previous step, and heat to dry;

[0023] (4) Calcining the powder obtained in the previous step at a temperature of 850°C and holding it for 5 hours;

[0024] (5) The powder synthesized in the previous step is granulated and pressed into a green body; the green body is a disc with a diameter of 15 mm and a thickness of 3.5 to 4.0 mm;

[0025] (6) Sintering the gr...

Embodiment 2

[0030] According to the molecular formula Ni in this embodiment 1-x-y Li x Fe y O batching, where x=0.04 and y=0.03. The initial raw material is selected from basic nickel carbonate NiCO 3 ·2Ni(OH) 2 ·4H 2 O, lithium carbonate Li 2 CO 3 , Iron citrate-hydrated FeC 6 H 5 O 7 ·NH 2 O. The material preparation is carried out according to the following experimental process steps:

[0031] (1) Press Ni 0.93 Li 0.04 Fe 0.03 O formula ingredients, weigh NiCO 3 ·2Ni(OH) 2 ·4H 2 O23.3262g, Li 2 CO 3 0.2956g, FeC 6 H 5 O 7 ·NH 2 O 1.4698g;

[0032] (2) The raw material NiCO weighed in the previous step 3 ·2Ni(OH) 2 ·4H 2 O and Li 2 CO 3 Dissolved in dilute nitric acid; FeC 6 H 5 O 7 ·NH 2 O is dissolved in deionized water by heating.

[0033] (3) Mix the two solutions prepared in the previous step, and use a magnetic stirring heater to stir and mix uniformly and heat to dry.

[0034] (4) The preparation process is the same as the steps (4) to (8) in Example 1.

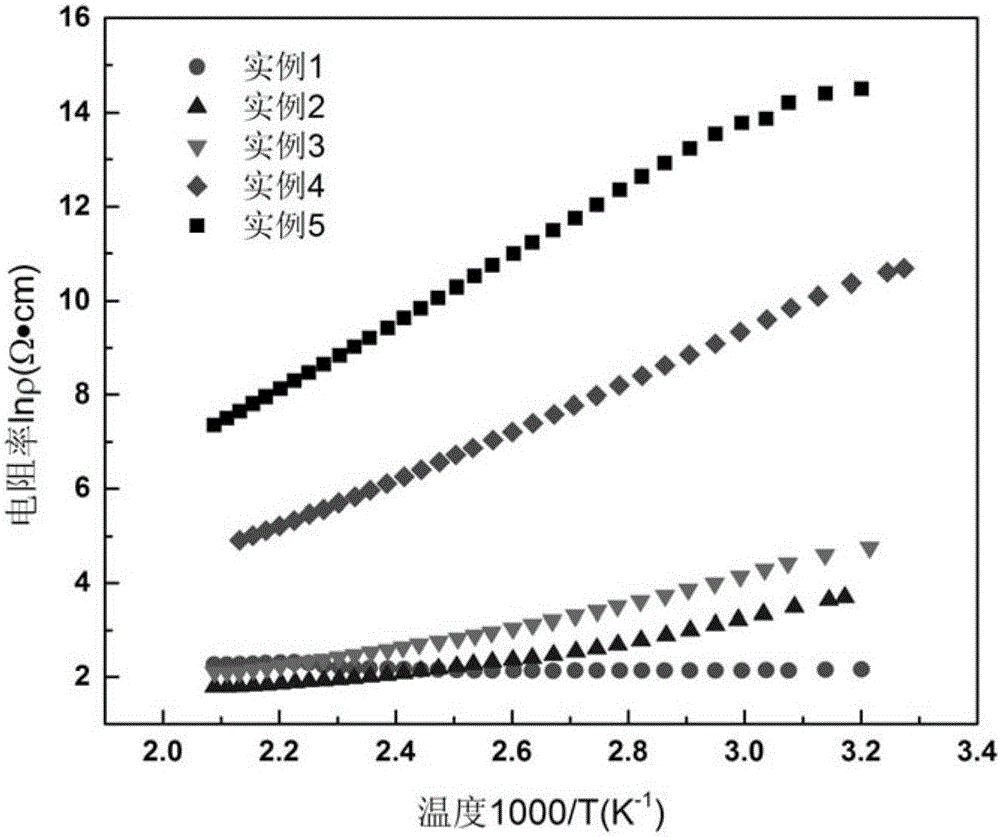

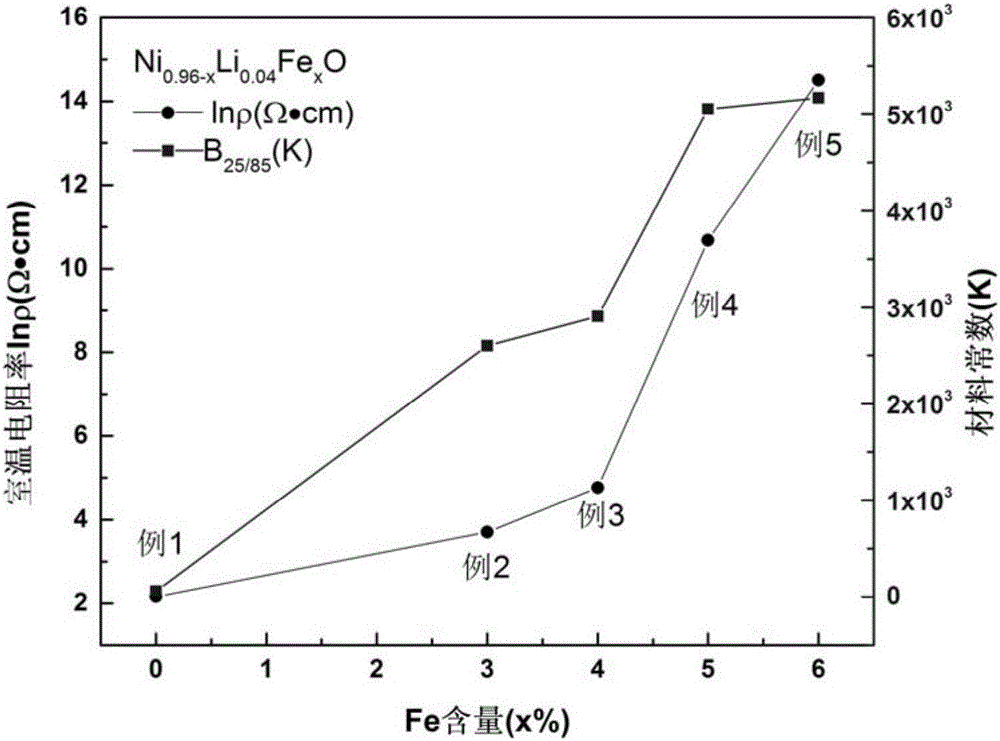

[0035] The properties of the pr...

Embodiment 3

[0037] This example is based on the molecular formula Ni 1-x-y Li x Fe y O batching, where x=0.04 and y=0.04. The initial raw material is NiCO basic nickel carbonate 3 ·2Ni(OH) 2 ·4H 2 O, lithium carbonate Li 2 CO 3 , Iron citrate-hydrated FeC 6 H 5 O 7 ·NH 2 O. The material preparation is carried out according to the following experimental process steps:

[0038] (1) Press Ni 1-x-y Li x Fe y O formula ingredients, weigh NiCO 3 ·2Ni(OH) 2 ·4H 2 O23.0754g, Li 2 CO 3 0.2956g, FeC 6 H 5 O 7 ·NH 2 O 1.9596g;

[0039] (2) The preparation process is the same as the steps (2) to (4) in Example 2.

[0040] The properties of the prepared materials are shown in Table 1, figure 1 with figure 2 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com