A phosphorus-containing composite flame retardant with core-shell structure, its preparation method and application

A composite flame retardant and core-shell structure technology, which is applied in the field of phosphorus-containing composite flame retardants with core-shell structure, can solve the problems of high cost, respective enrichment of flame retardants, complicated formulations, etc., and achieves low cost and preparation process. Simple and easy to implement, enhance the effect of flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

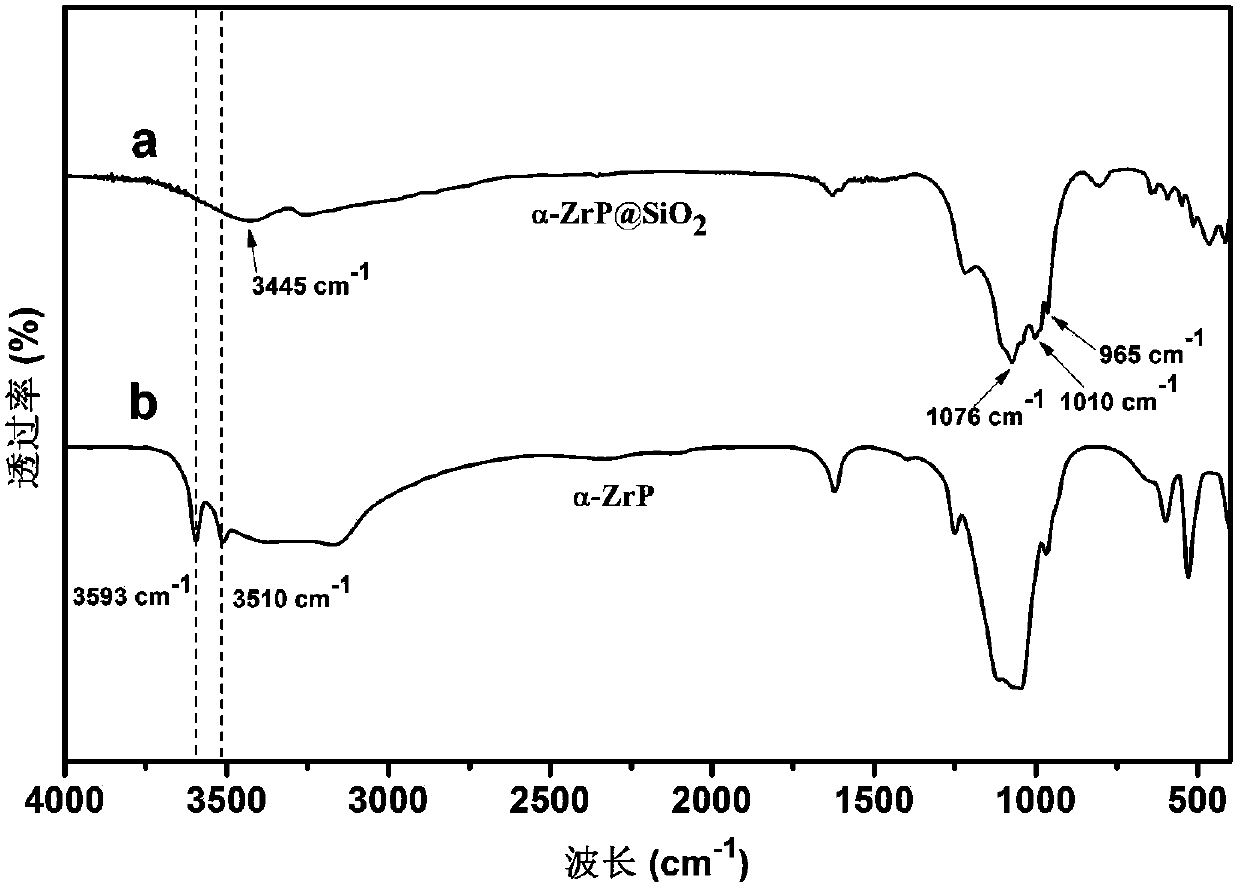

[0047] The preparation method of the phosphorus-containing composite flame retardant of core-shell structure is as follows:

[0048] Disperse 15g of zirconium phosphate with a particle size of 1.0 μm in 300ml of alcohol-water mixed solvent (obtained by mixing ethanol and water at a mass ratio of 1:10), disperse while stirring and ultrasonic treatment, and the mechanical stirring speed is 300r / min, The power of ultrasonic treatment is 100kW, the temperature is controlled at room temperature, and the dispersion time is 120min. Then add 5ml of sucrose glyceride, add ammonia water to adjust the pH to 8, then add 10g of 3-aminopropyltrimethoxysilane, and heat up to 130°C for 5h. Filter and wash with ethanol and deionized water three times, dry to constant weight, then place in a muffle furnace for 5 hours at 300°C in a nitrogen atmosphere, and cool to room temperature to obtain a pale gray powder that is the core-shell structure. Phosphorous compound flame retardant.

[0049] The ...

Embodiment 2

[0054] The preparation method of the phosphorus-containing composite flame retardant of core-shell structure is as follows:

[0055] Disperse 15g of zirconium phosphate with a particle size of 1.0 μm in 300ml of alcohol-water mixed solvent (obtained by mixing ethanol and water at a mass ratio of 1:4), and disperse while stirring and ultrasonic treatment, with a mechanical stirring speed of 300r / min. The power of ultrasonic treatment is 100kW, the temperature is controlled at room temperature, and stirred for 120min. After that, add 5ml of octylphenol polyoxyethylene ether, then add ammonia water to adjust the pH of the solution to 8, and then add 15g of aminopropylmethyldiethoxysilane , raised the temperature to 100°C, reacted for 6h, filtered and washed three times with ethanol and deionized water respectively, dried in an oven to constant weight, then placed in a muffle furnace and treated at 400°C in a nitrogen atmosphere for 4h, cooled to room temperature, the obtained off...

Embodiment 3

[0058] The preparation method of the phosphorus-containing composite flame retardant of core-shell structure is as follows:

[0059] Disperse 15g of zirconium phosphate with a particle size of 1.0 μm in 300ml of alcohol-water mixed solvent (obtained by mixing ethanol and water at a mass ratio of 1:6), and disperse while stirring and ultrasonic treatment, with a mechanical stirring speed of 300r / min. The power of ultrasonic treatment is 100kW, the temperature is controlled at room temperature, and stirred for 120min. After that, add 5ml of sorbitan monostearate, add ammonia water to adjust the pH to 8, and then add 20g of 3-(methacryloyloxy)propyltrimethoxy base silane, raise the temperature to 80°C, and react for 10h. Afterwards, filter and wash with ethanol and deionized water three times respectively, dry in an oven to constant weight, then place in a muffle furnace for high temperature treatment at 500°C and a nitrogen atmosphere for 2 hours, and cool to room temperature. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com