A kind of detection method of maldi-tof-ms of polythiocarbonate compound

A technology of MALDI-TOF-MS and polythiocarbonate, which is applied in the detection field of MALDI-TOF-MS, can solve the problems such as rarely seen polythiocarbonate compounds, achieve the best ionic strength and avoid drift and measurement errors, avoiding the effect of operating steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, the MALDI-TOF-MS detection method of polythiocarbonate compound, comprises the following steps:

[0027] a) Select the sample target Ground steel stainless steel target plate;

[0028] b) Matrix solution preparation: Dithranol (DIT) was used as the matrix, dissolved in THF at a concentration of 10 mg / mL; no ionizing reagent was added;

[0029] c) The sample is made into a THF solution of 10 mg / mL;

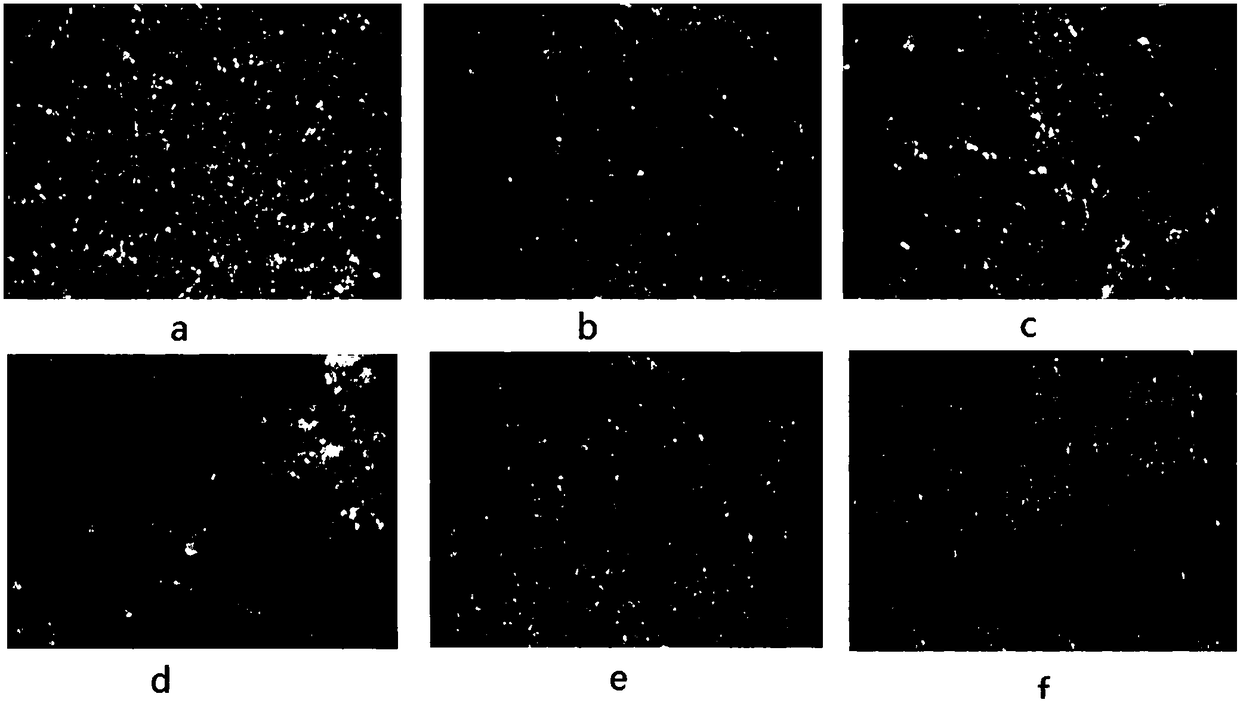

[0030] d) Optimizing the spotting ratio: Spot the matrix solution and the sample solution at a volume ratio of 10:2, take 1 μL of the mixed solution and spot it on the sample target, and let it dry naturally to obtain a thin layer of MALDI matrix and sample crystals, and perform MALDI-TOF -MS analysis.

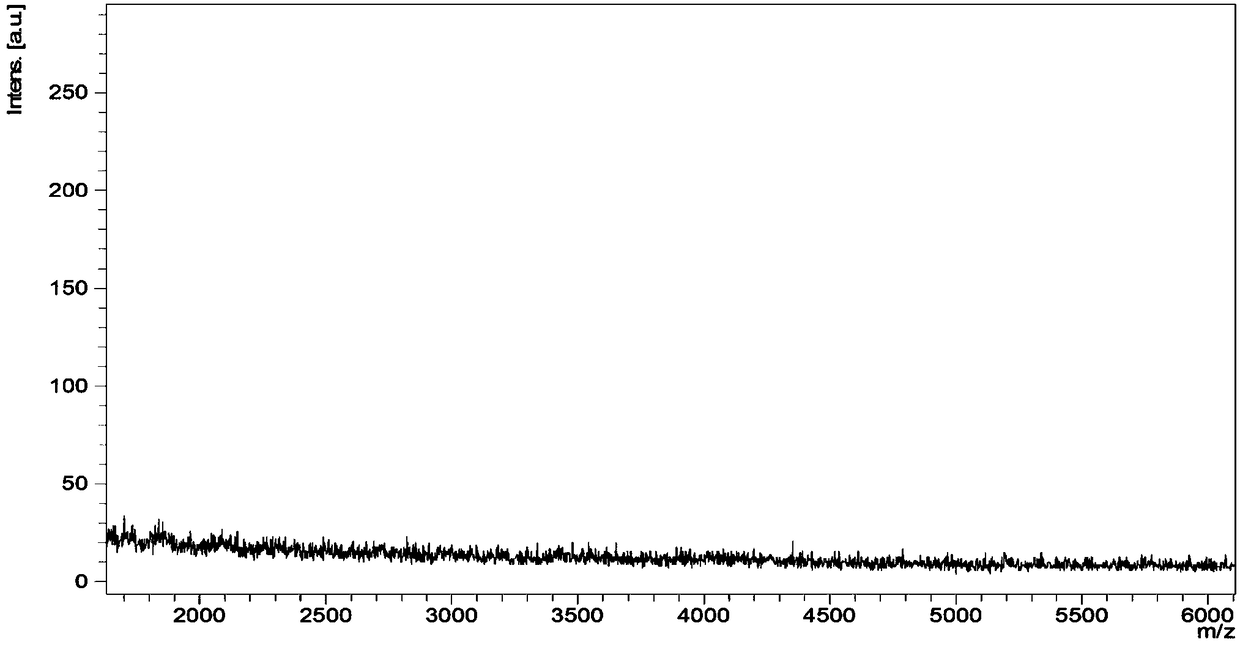

[0031] Mass spectrometry conditions: Ultraflex matrix-assisted laser desorption ionization time-of-flight mass spectrometer (MALDI-TOF-MS) (Bruker Daltonic, Germany), positive linear mode selected, accelerating voltage 20KV, scan range of m / z2000-6000, the ...

Embodiment 2

[0034] Embodiment 2, the MALDI-TOF-MS detection method of polythiocarbonate compound, comprises the following steps:

[0035] a) Select the sample target Ground steel stainless steel target plate;

[0036] b) Preparation of matrix solution: using DIT as matrix, dissolve it in THF at a concentration of 10 mg / mL; potassium trifluoroacetate is used as the ionization reagent of the sample, and prepare a 2.5 mg / mL solution;

[0037] c) The sample is made into a THF solution of 10 mg / mL;

[0038] d) Optimizing the spotting ratio: spotting the matrix solution, sample solution and salt solution at a ratio of 10:2:0.5 (volume ratio), taking 1 μL of the mixed solution to spot on the sample target, and drying naturally to obtain MALDI matrix and sample crystallization The thin layer was analyzed by MALDI-TOF-MS.

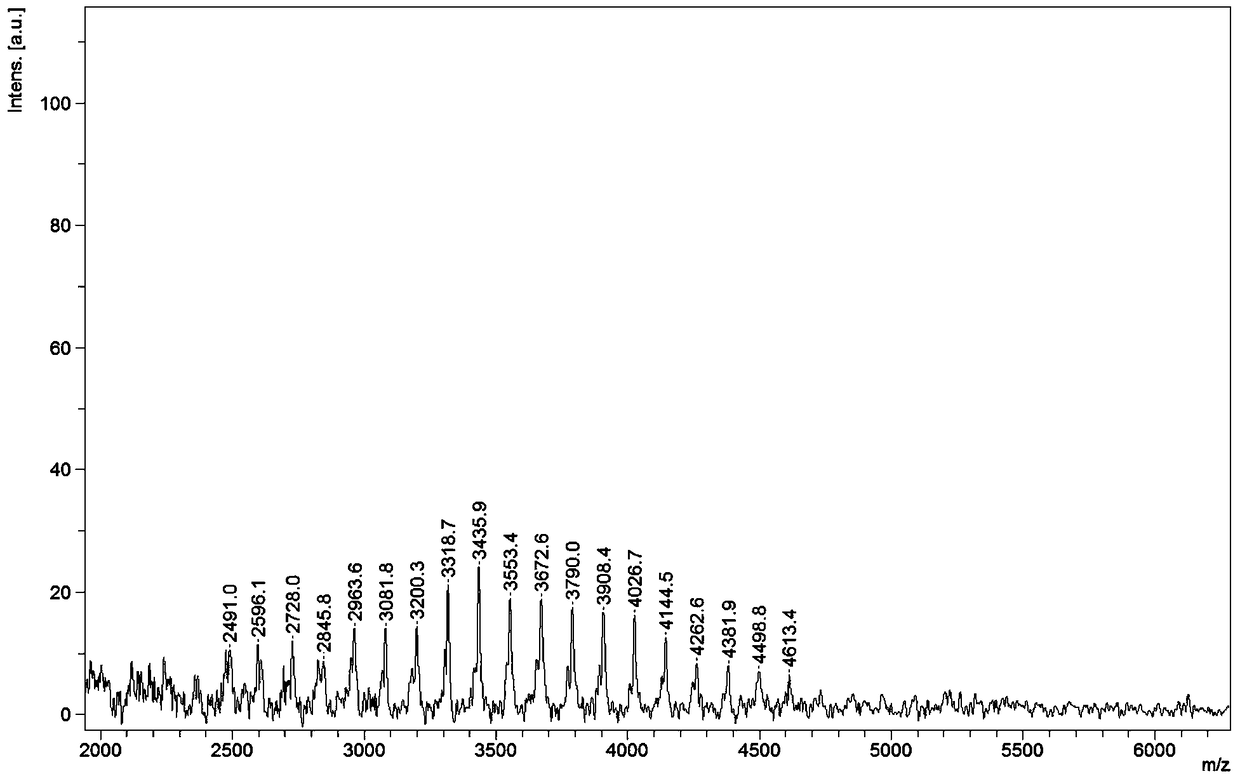

[0039] Mass spectrometry conditions: Ultraflex matrix-assisted laser desorption ionization time-of-flight mass spectrometer (MALDI-TOF-MS) (Bruker Daltonic, Germany), positiv...

Embodiment 3

[0041] Embodiment 3, the MALDI-TOF-MS detection method of polythiocarbonate compound, comprises the following steps:

[0042] a) Select the sample target Ground steel stainless steel target plate;

[0043]b) Matrix solution preparation: use DIT as the matrix, dissolve it in THF at a concentration of 10 mg / mL; use potassium trifluoroacetate as the ionization reagent of the sample, and prepare a THF solution of 2.5 mg / mL;

[0044] c) The sample is made into a THF solution of 10 mg / mL;

[0045] d) Optimizing the spotting ratio: Spotting the matrix solution, sample solution and salt solution at a ratio of 10:2:1 (volume ratio), taking 1 μL of the mixed solution to spot on the sample target, and drying naturally to obtain MALDI matrix and sample crystallization The thin layer was analyzed by MALDI-TOF-MS.

[0046] Mass spectrometry conditions: Ultraflex matrix-assisted laser desorption ionization time-of-flight mass spectrometer (MALDI-TOF-MS) (Bruker Daltonic, Germany), positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com