Nitrogen-doped graphene loaded Pd/Co catalyst and preparation method thereof

A nitrogen-doped graphene and catalyst technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of dispersion, poor stability, catalytic activity to be improved, and composite catalysts are easy to agglomerate, so as to promote dispersion and desorption Accompanied by further reaction, the effect of strengthening the catalytic performance of oxygen reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

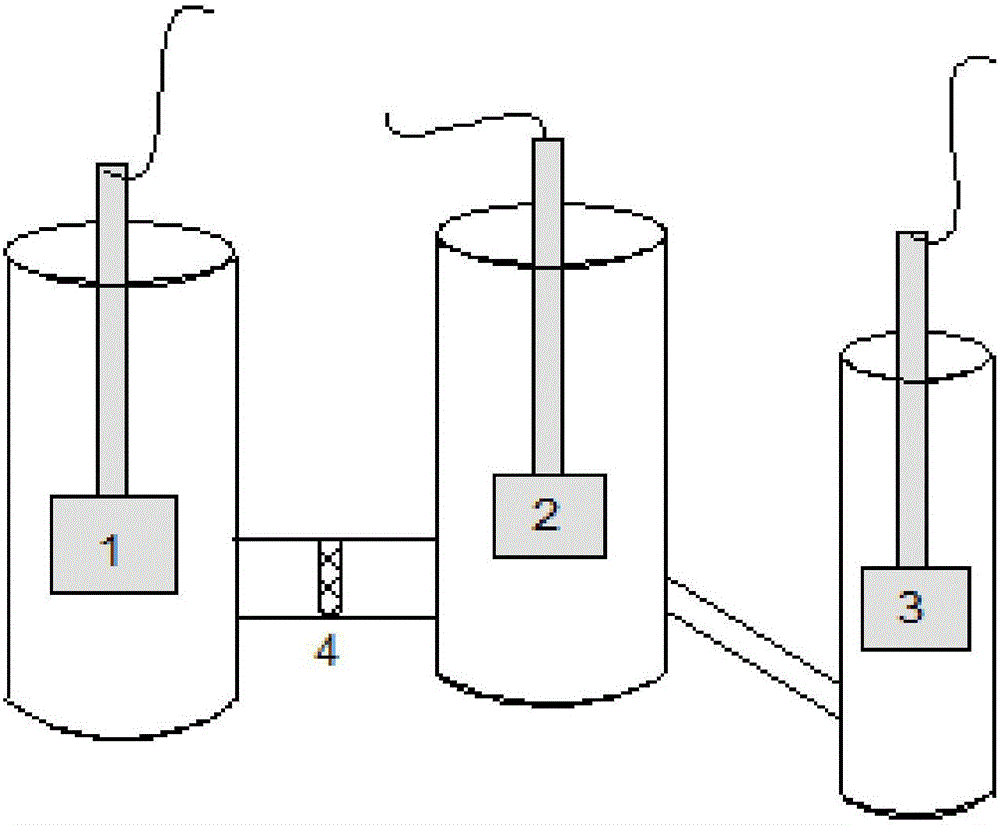

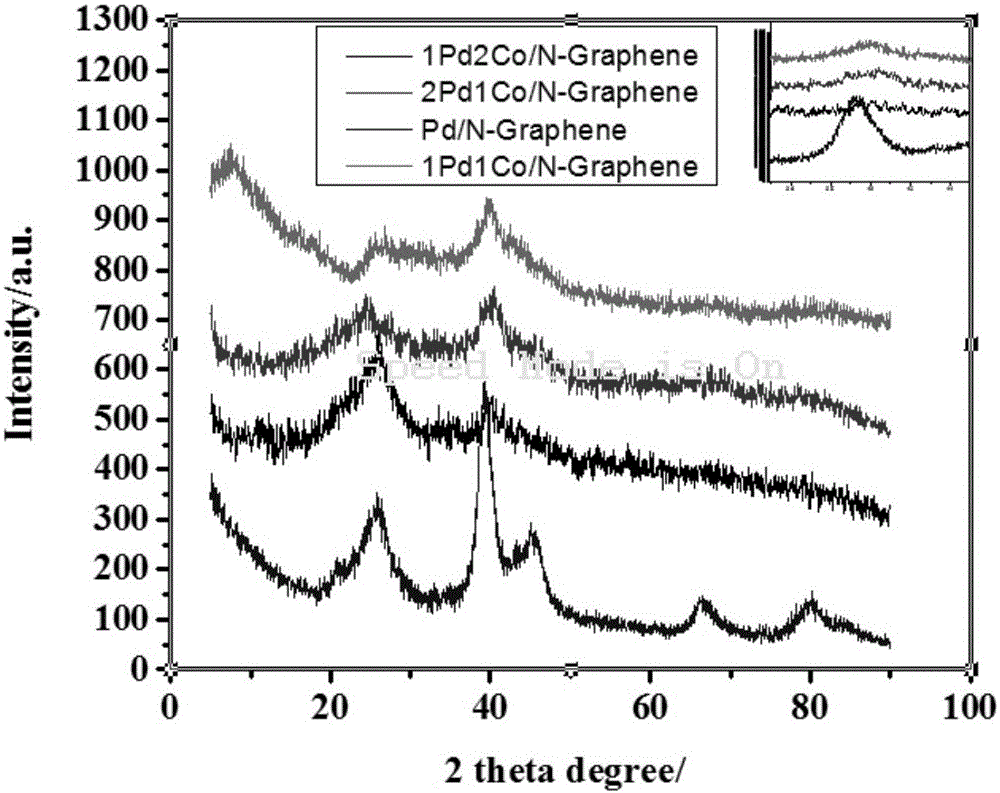

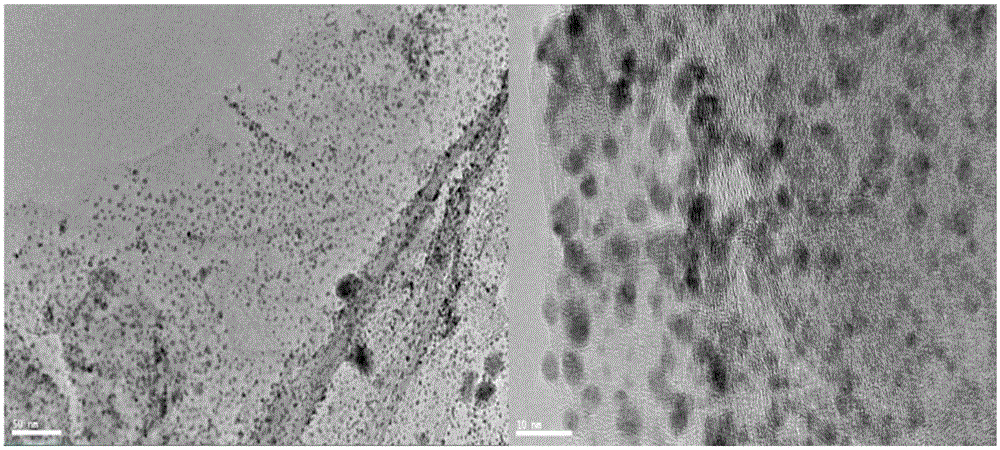

[0035] A nitrogen-doped graphene-supported Pd / Co catalyst is prepared from the following raw materials in parts by weight: Co(NO 3 ) 2 ·6H 2 100 parts of O, 200 parts of nitrogen-doped graphene, 1175 parts of potassium borohydride; also includes an appropriate amount of 0.05mol / L of PdCl 2 solution, so that the molar ratio of Pd to Co is 1:2;

[0036] Wherein, the nitrogen-doped graphene is obtained by the following method: 1 part by weight of graphene oxide is added to 1350 parts by weight of ammonia water, ultrasonically dispersed for 10 minutes to the ink state, and then 2700 parts by weight are added ammonia water, and moved into a hydrothermal reaction kettle of suitable size, so that the volume of the reactant was 2 / 3 of the volume of the hydrothermal reaction kettle, reacted at 200°C for 4.5 hours, cooled to room temperature after the reaction and washed with deionized water until the product was Ammonia-containing water, and then dried at 60°C to obtain nitrogen-doped...

Embodiment 2

[0043] A nitrogen-doped graphene-supported Pd / Co catalyst is prepared from the following raw materials in parts by weight: Co(NO 3 ) 2 ·6H 2 100 parts of O, 250 parts of nitrogen-doped graphene, 1250 parts of potassium borohydride; also includes an appropriate amount of 0.05mol / L of PdCl 2 solution, so that the molar ratio of Pd to Co is 2:1;

[0044] Wherein, the nitrogen-doped graphene is obtained by the following method: 1 part by weight of graphene oxide is added to ammonia water of 1400 parts by weight, ultrasonically dispersed for 15 minutes to the ink state, and then 2800 parts by weight are added ammonia water, and moved into a hydrothermal reactor of suitable size, so that the volume of the reactant was 2 / 3 of the volume of the hydrothermal reactor, reacted at 230°C for 5.5 hours, cooled to room temperature after the reaction and washed with deionized water until the product was Ammonia-containing water, then dried at 75°C to obtain nitrogen-doped graphene;

[004...

Embodiment 3

[0051] A nitrogen-doped graphene-supported Pd / Co catalyst is prepared from the following raw materials in parts by weight: Co(NO 3 ) 2 ·6H 2 100 parts of O, 227 parts of nitrogen-doped graphene, 1197 parts of potassium borohydride; also includes an appropriate amount of 0.05mol / L of PdCl 2 solution, so that the molar ratio of Pd to Co is 1:1;

[0052] Wherein, the nitrogen-doped graphene is obtained by the following method: 1 part by weight of graphene oxide is added to 1365 parts by weight of ammonia water, ultrasonically dispersed for 13 minutes to ink-like, and then 2730 parts by weight are added Ammonia, and moved into a suitable size hydrothermal reactor, so that the volume of the reactant is 2 / 3 of the volume of the hydrothermal reactor, reacted at 210 ° C for 5 hours, cooled to room temperature after the reaction and washed with deionized water until the product Ammonia-containing water, then dried at 70°C to obtain nitrogen-doped graphene;

[0053] Graphene oxide i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com