Larotaxel water-soluble powder injection preparation and application

A technology of water-soluble powder and larotaxel, which can be applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, powder delivery, etc., and can solve the problem of larotaxel nano-polymer micelles Relevant preparation research and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

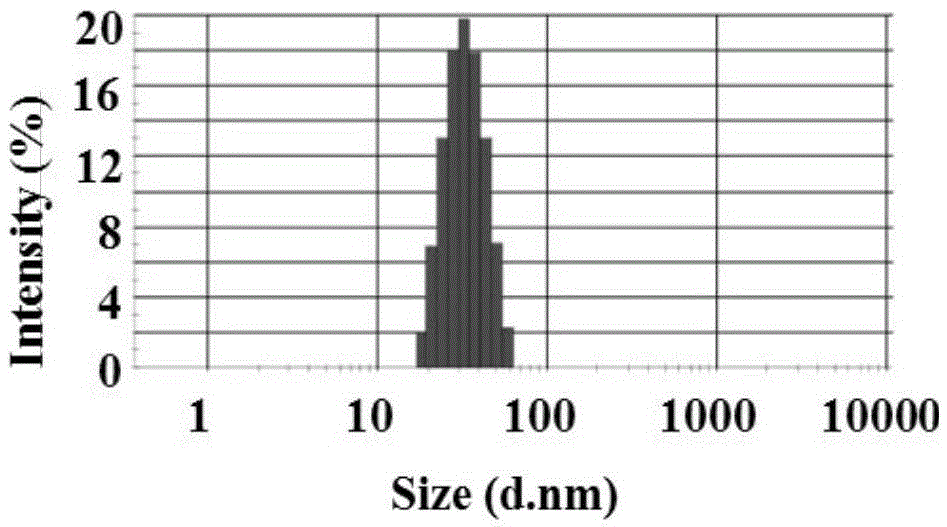

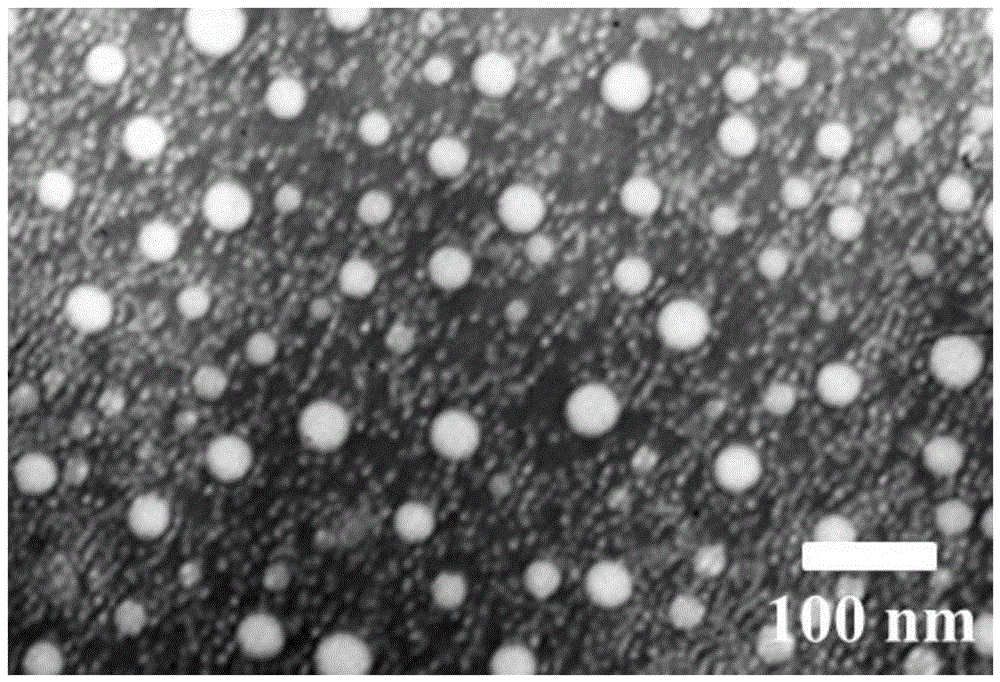

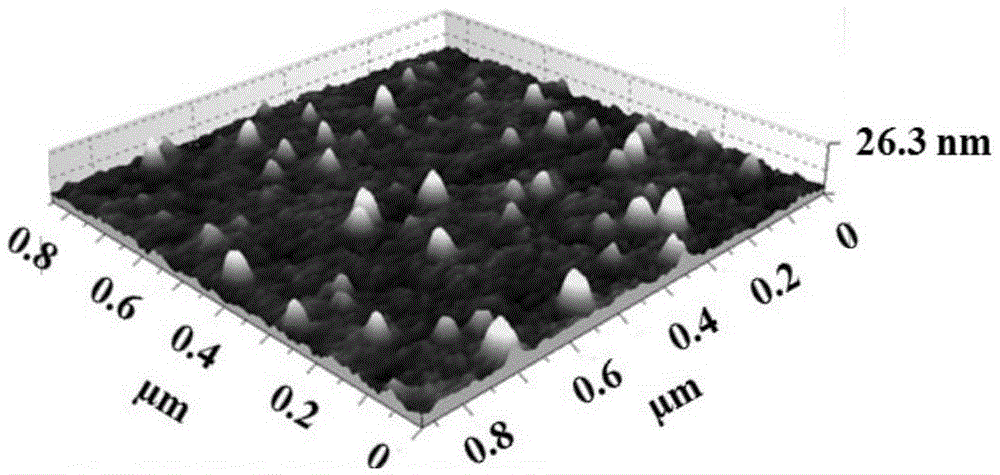

[0031] Weigh 180mg carrier material (mPEG 2000 -PDLLA 1700 ) and 20 mg of larotaxel were placed in a round bottom flask, 10 mL of absolute ethanol was added, and the carrier material and the drug were fully dissolved by ultrasonication. The solution was placed in a rotary evaporator at 40° C. for 60 minutes to evaporate the organic solvent completely to obtain a dry and transparent mixed film matrix. Then add 10mL of water for injection preheated at 60°C, hydrate to form micelles under stirring conditions, add mannitol, first pass through a 0.45μm filter membrane for coarse filtration, and then pass through a 0.22μm sterile filter membrane for fine filtration to sterilize, the filtrate freeze-dried to obtain a sample.

Embodiment example 2

[0033] Weigh 150mg carrier material (mPEG 2000 -PCL 2000 ) and 50 mg of larotaxel were placed in a lyophilized bottle, 5 ml of tert-butanol was added, and the carrier material and the drug were fully dissolved by ultrasonication. The solution is lyophilized and the organic solvent is completely removed to obtain a mixed matrix of drug and carrier material. Then add 10mL of water for injection preheated at 60°C, hydrate to form micelles under the condition of stirring, add sucrose, first pass through a 0.45μm filter membrane for coarse filtration, and then pass through a 0.22μm sterile filter membrane for fine filtration to sterilize, and the filtrate is frozen Dry to get a sample.

Embodiment example 3

[0035] Weigh 180mg carrier material (mPEG 5000 -PGA 6000 ) and 20 mg of larrotaxel were placed in a round bottom flask, 5 ml of tetrahydrofuran was added, and the carrier material and the drug were fully dissolved by ultrasonication. The solvent was distilled under reduced pressure to completely remove the organic solvent to obtain a dry and transparent mixed film matrix. Then add 10 mL of water for injection preheated at 50°C, vortex for 3 minutes, add trehalose, pass the hydration solution through a 0.45 μm filter membrane for coarse filtration, and then pass through a 0.22 μm filter membrane for fine filtration to sterilize, and the filtrate is freeze-dried to obtain sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com