Laminated film

A film and film technology, applied in the field of laminated films, can solve the problems of reduced welding heat resistance, poor appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

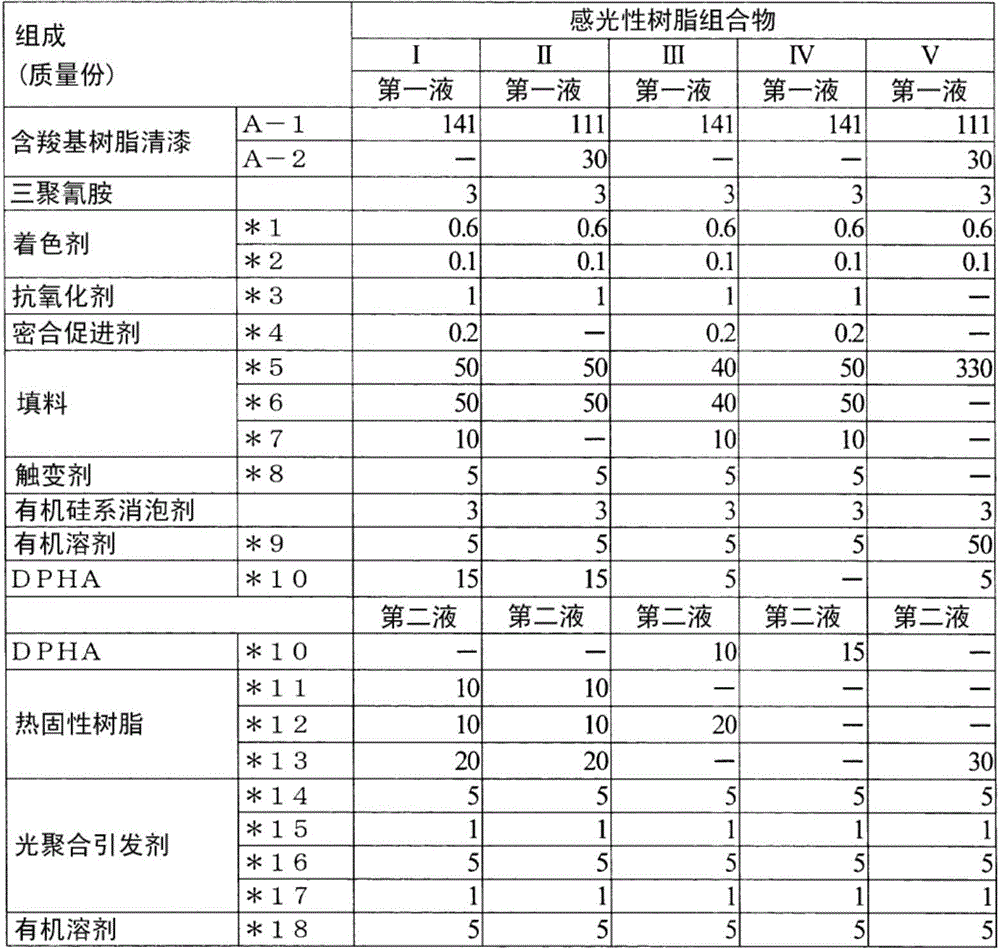

[0159] Hereinafter, examples, comparative examples, and test examples of the present invention are shown, and the present invention will be specifically described, but the present invention is not limited to the following examples. In addition, below, "part" and "%" are mass standards unless otherwise indicated.

[0160] (Synthesis of Carboxyl-containing Resin A-1)

[0161] In an autoclave equipped with a thermometer, a nitrogen gas introduction device, an alkylene oxide introduction device, and a stirring device, 119.4 g of a novolak-type cresol resin (Shonol CRG951 manufactured by Showa Denko Co., Ltd., OH equivalent: 119.4) and 1.19 g of potassium hydroxide were charged. g and 119.4 g of toluene, while stirring, nitrogen replacement was carried out in the system, and then heating was carried out to raise the temperature. Next, slowly drop 63.8g of propylene oxide, at 125-132°C, 0-4.8kg / cm 2 Allow it to react for 16 hours. Thereafter, after cooling to room temperature, 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com