Kaoline-2-pyrazine carboxylic acid intercalation compound and preparation method thereof

A technology of pyrazine carboxylic acid and compound, applied in the field of new compound and preparation thereof, can solve the problems of unsatisfactory intercalation effect, time-consuming and labor-intensive and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Add 600ml of distilled water to 10g of kaolin raw soil, and ultrasonically clean it for 1 hour to obtain water-washed kaolin; add 5g of water-washed kaolin, 50ml of dimethyl sulfoxide and 5ml of deionized water into a 100ml round-bottomed flask, and stir at room temperature for 12 hours to obtain K- DMSO precursor; 1g of the precursor and 1g of 2-pyrazinecarboxylic acid were sealed in a 25ml stainless steel reactor, reacted at 90°C for 5 hours, added 10ml of sodium hydroxide aqueous solution, centrifuged, washed, and dried to obtain K-2-PA .

Embodiment 2

[0019] Embodiment 2: Add 600ml distilled water to 10g kaolin raw soil, and ultrasonically clean it for 2 hours to obtain water-washed kaolin; add 5g water-washed kaolin, 50ml dimethyl sulfoxide and 5ml deionized water to a 100ml round-bottomed flask, stir at room temperature for 12 hours, and obtain K- DMSO precursor; 1g of the precursor and 1g of 2-pyrazinecarboxylic acid were sealed in a 25ml stainless steel reactor, and after 8 hours of reaction at 120°C, 20ml of sodium hydroxide aqueous solution was added, centrifuged, washed, and dried to obtain K-2-PA .

Embodiment 3

[0020] Embodiment 3: Add 600ml distilled water to 10g kaolin raw soil, and ultrasonically clean it for 0.5 hours to obtain water-washed kaolin; add 5g water-washed kaolin, 50ml dimethyl sulfoxide and 5ml deionized water to a 100ml round-bottomed flask, stir at room temperature for 24 hours, and obtain K- DMSO precursor; 1g of the precursor and 1g of 2-pyrazinecarboxylic acid were sealed in a 25ml stainless steel reactor, and after 10 hours of reaction at 160°C, 15ml of sodium hydroxide aqueous solution was added, centrifuged, washed, and dried to obtain K-2-PA .

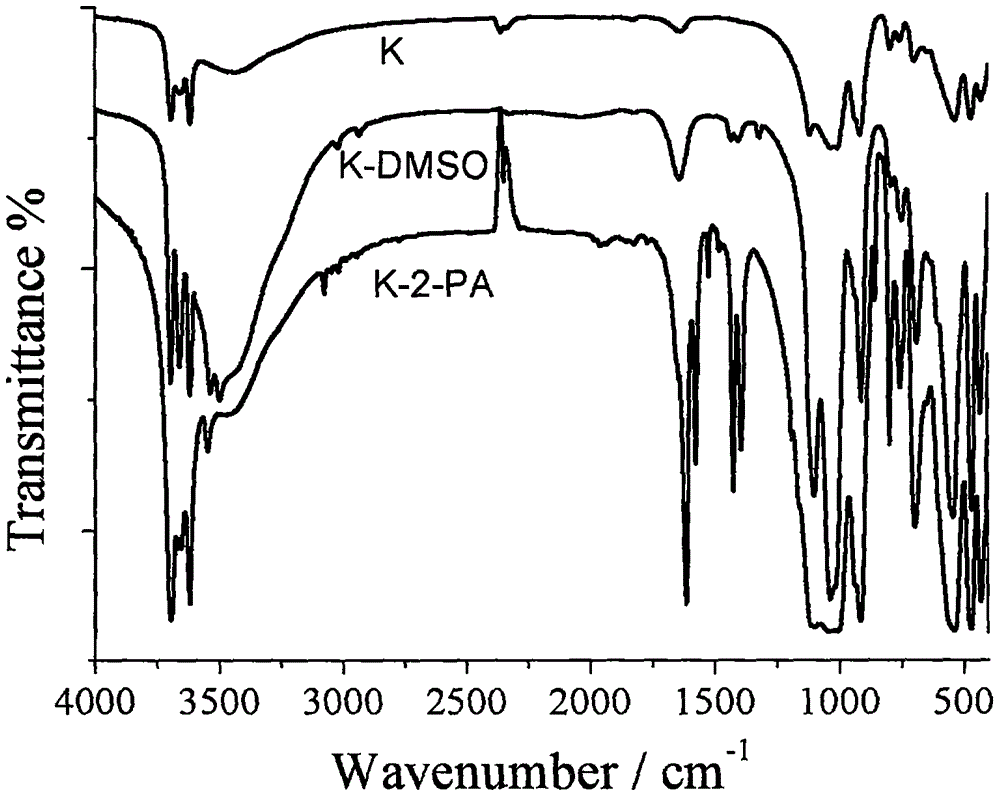

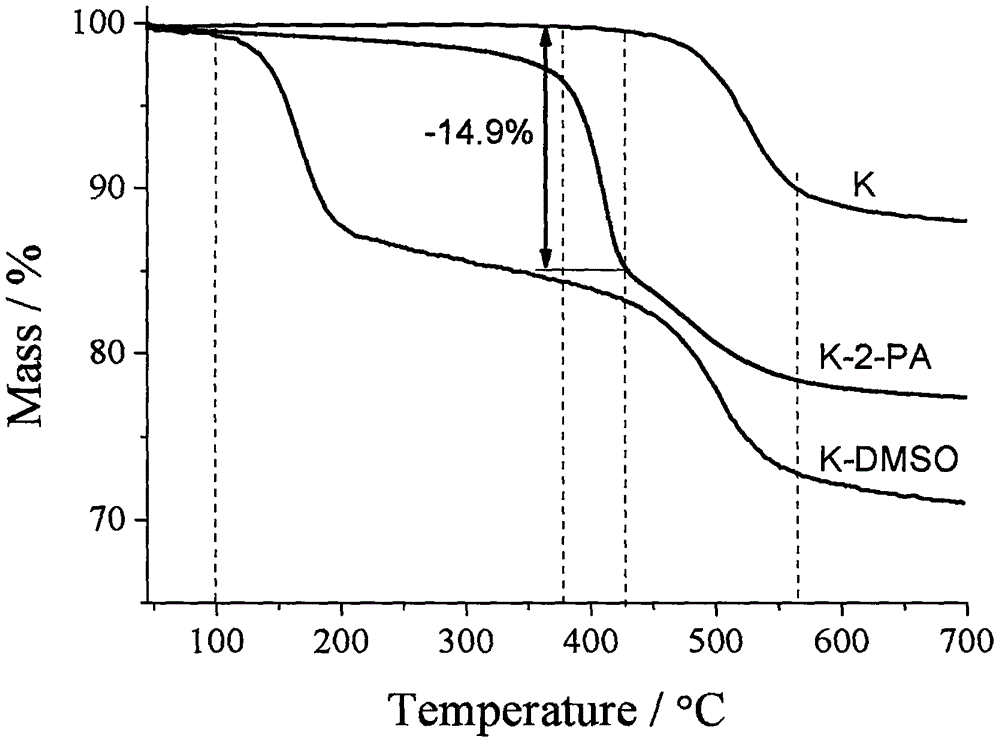

[0021] The characterization of kaolin-2-pyrazinecarboxylic acid intercalation compound of the present invention:

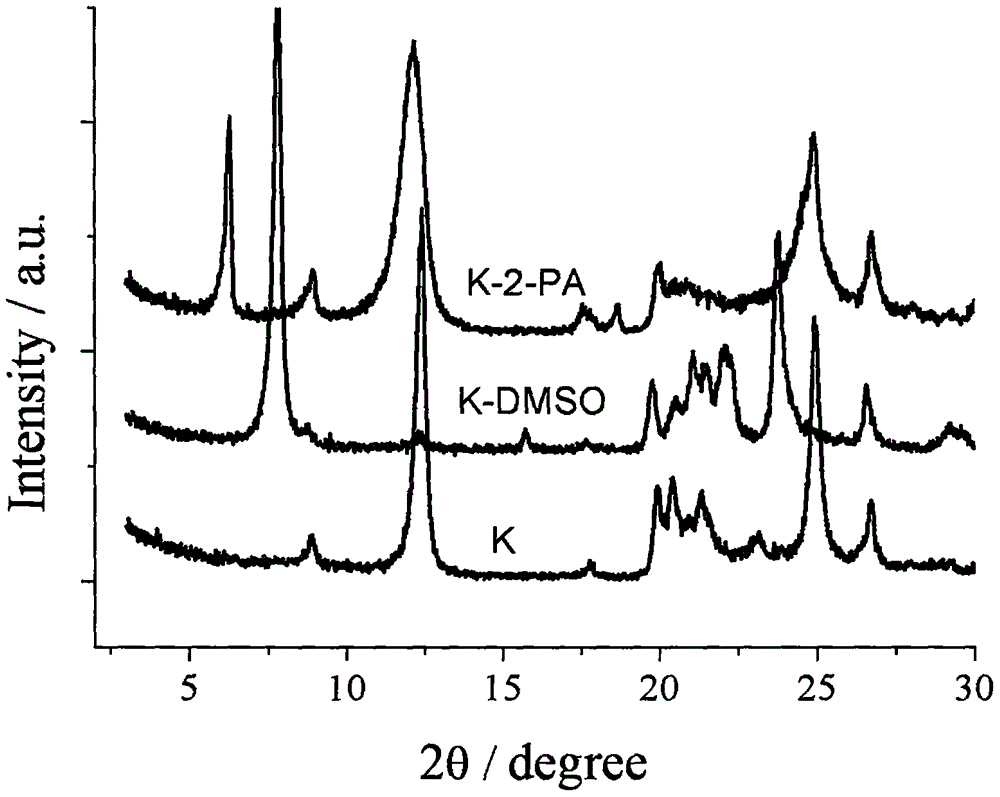

[0022] (1) X-ray diffraction characterization

[0023] Powder diffraction data were collected on a Bruker D8 ADVANCE diffractometer operating at a current of 40 mA and a voltage of 40 kV. Copper target X-rays using graphite monochromatization. Data collection was done using 2q / q scan mode, with contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com