Hierarchical pore ZSM-5 molecular sieve with nanosheet layer structure and synthesis method thereof

A ZSM-5, nanosheet technology, applied in the field of molecular sieve synthesis, can solve the problems of complex preparation process, limited research field development and industrial application value, expensive synthesis raw materials, etc., and achieves simplified steps, high yield and reduced preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Potassium hydroxide (0.939g) was dissolved in 36.166g deionized water to form solution A, and the weighed aluminum isopropoxide (0.274g) was added to part A solution (40% of the total mass) and stirred 2h to form solution B;

[0033] (2) Slowly add an appropriate amount of ethyl tetrasilicate (5.58g) dropwise into the solution of part A (30% of the total mass) and stir for 2 hours to form solution C;

[0034] (3) Add B to C and stir for 5 hours to form solution D;

[0035] (4) Add hexadecyltrimethylammonium bromide (0.488g) into part A solution (30% of the total mass), after stirring for 1-3h, add into D solution and continue stirring for 1h to form a reaction mixture, Hydrothermal crystallization at 175°C for 15 days;

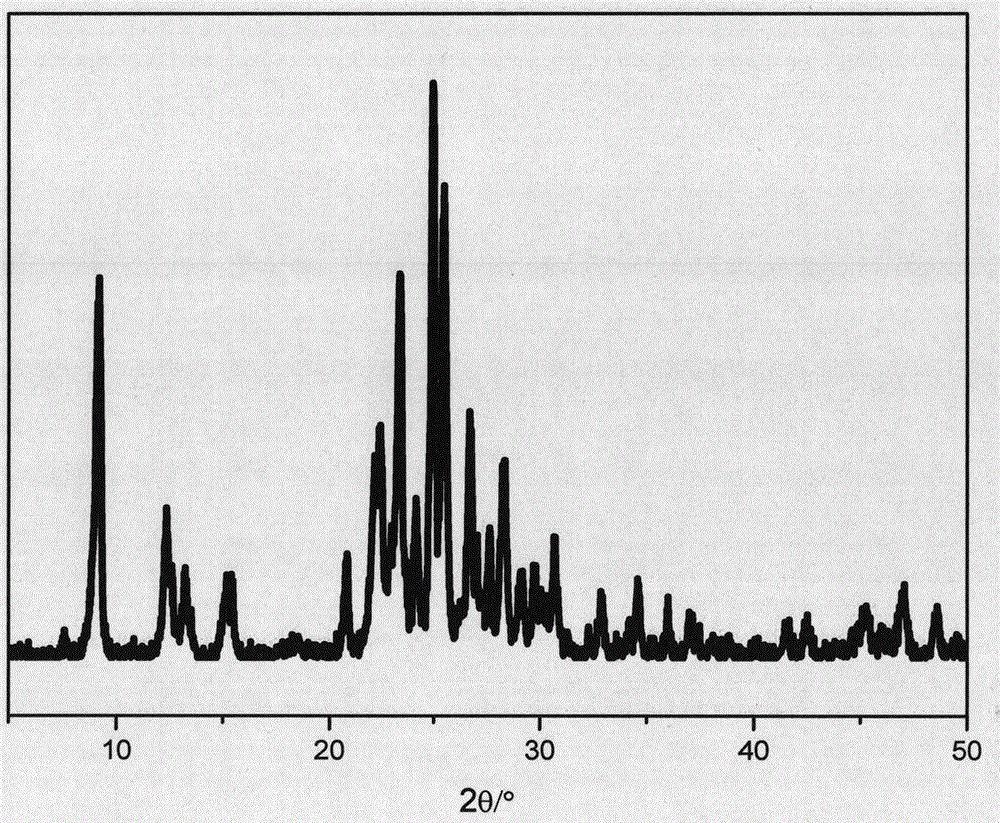

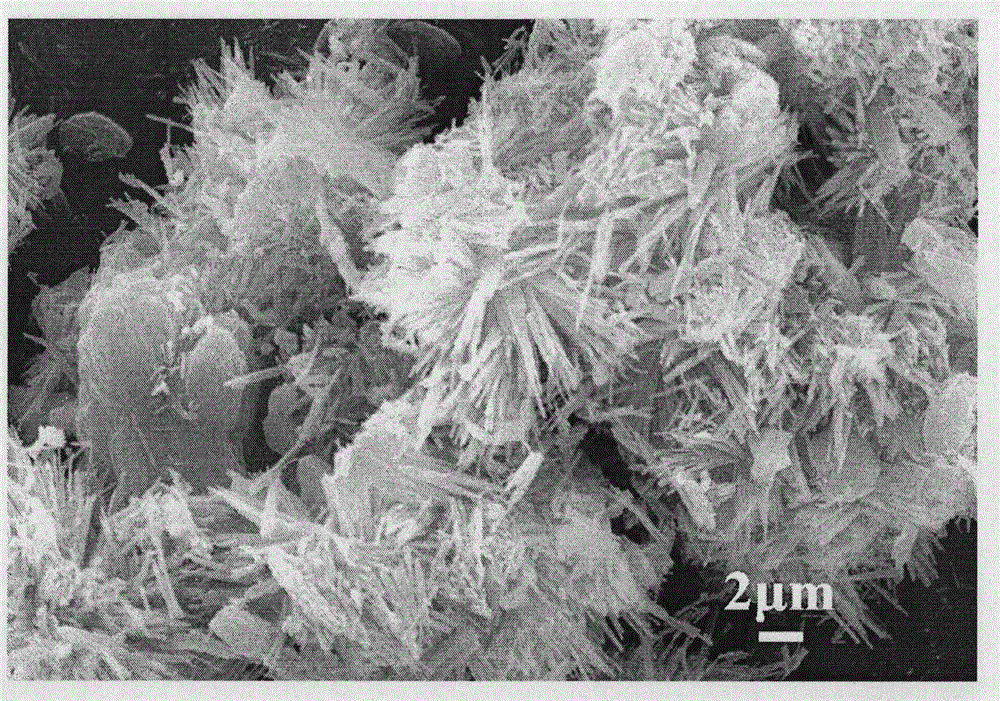

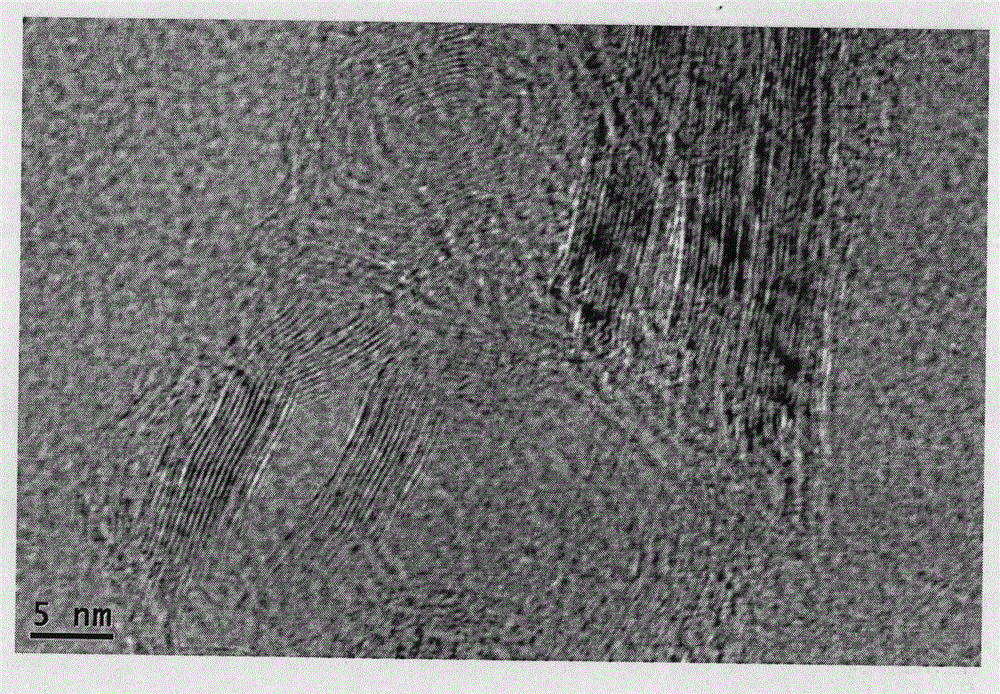

[0036] (5) After the reaction, the sample was taken out, rinsed with a large amount of water, dried overnight at 120°C, and then baked in a muffle furnace at 550°C for 6 hours. The porous grade ZSM-5 molecular sieve with nanosheet structure can b...

Embodiment 2

[0039] (1) Potassium hydroxide (0.939g) was dissolved in 36.166g deionized water to form solution A, and the weighed pseudo-boehmite (0.247g) was added to part A solution (40% of the total mass) Stir for 4h to form solution B;

[0040] (2) Slowly add an appropriate amount of ethyl tetrasilicate (5.58g) dropwise into the solution of part A (30% of the total mass) and stir for 2 hours to form solution C;

[0041] (3) Add B to C and stir for 5 hours to form solution D;

[0042] (4) Hexadecyltrimethylammonium bromide (0.488g) was added to part A solution (30% of the total mass), stirred for 2h, then added to D solution and continued to stir for 1h to form a reaction mixture, at 175 Hydrothermal crystallization at ℃ for 15d;

[0043](5) After the reaction, the sample was taken out, rinsed with a large amount of water, dried overnight at 120°C, and then baked in a muffle furnace at 550°C for 6 hours. The porous grade ZSM-5 molecular sieve with nanosheet structure can be obtained....

Embodiment 3

[0045] (1) Dissolve potassium hydroxide (0.939g) in 36.166g deionized water to make solution A, add weighed aluminum powder (0.147g) to part A solution (40% of the total mass) and stir for 2h to form Solution B;

[0046] (2) Slowly add an appropriate amount of tetraethyl orthosilicate (5.58 g) dropwise into the solution of part A (30% of the total mass) and stir for 3 hours to form solution C;

[0047] (3) Add B to C and stir for 5 hours to form solution D;

[0048] (4) Hexadecyltrimethylammonium bromide (0.488g) was added to part A solution (30% of the total mass), stirred for 2h, then added to D solution and continued to stir for 1h to form a reaction mixture, at 175 Hydrothermal crystallization at ℃ for 15d;

[0049] (5) After the reaction, the sample was taken out, rinsed with a large amount of water, dried overnight at 120°C, and then baked in a muffle furnace at 550°C for 6 hours. The porous grade ZSM-5 molecular sieve with nanosheet structure can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com