Polyaspartic acid for water treatment scale inhibitor, as well as preparation method and application of polyaspartic acid

A technology of polyaspartic acid and scale inhibitor, which is applied in water/sludge/sewage treatment, special treatment targets, chemical instruments and methods, etc., can solve the problems of lack of structure and performance, and achieve high degree of freedom and good The effect of scale inhibition performance and fast biodegradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

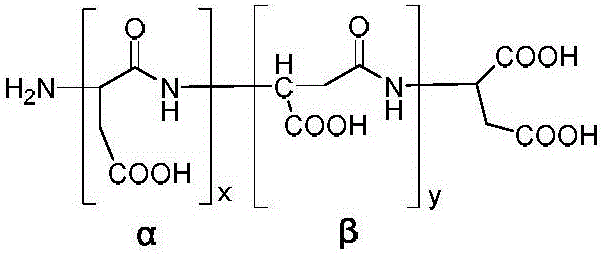

Method used

Image

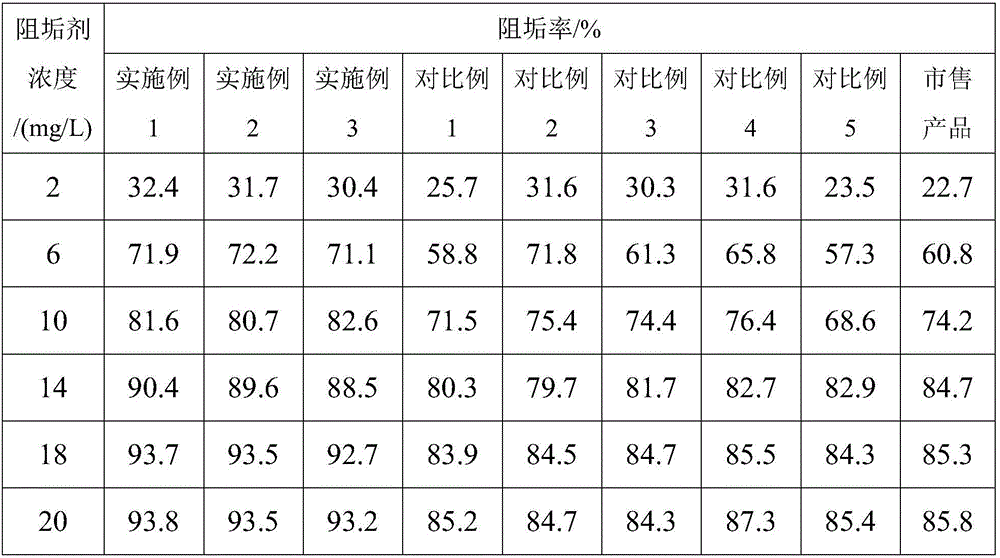

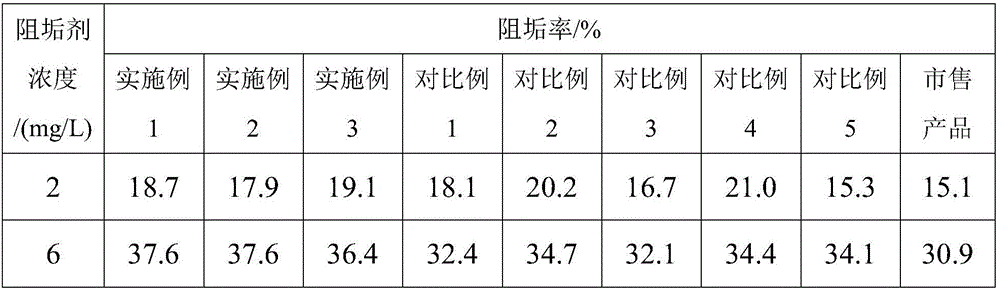

Examples

preparation example 1

[0019] Preparation of polysuccinimide

[0020] A certain amount of 1000g L-aspartic acid and 13g H 3 PO 4 Add it to liquid paraffin, heat to 200°C and react for 2 hours, separate the water produced by the reaction with a water separator, cool down to 35°C, and separate the liquid paraffin by suction filtration, wash the solid product three times with ethanol and distilled water respectively, and place at 80°C Dry in a constant temperature drying oven for 10 hours to obtain a light yellow polysuccinimide powder. After testing, the mass average molecular weight of the polysuccinimide is 6810, and it is ready for use.

preparation example 2

[0022] Preparation of polysuccinimide

[0023] A certain amount of 1000g L-aspartic acid and 15g H 3 PO 4 Add it to liquid paraffin, heat to 200°C and react for 2.5 hours, separate the water produced by the reaction with a water separator, cool down to 35°C, and separate the liquid paraffin by suction filtration, wash the solid product with ethanol and distilled water three times respectively, and place at 80°C Dry in a constant temperature drying oven for 10 hours to obtain light brown polysuccinimide powder. After testing, the mass average molecular weight of polysuccinimide is 7530, and it is ready for use.

preparation example 3

[0025] Preparation of polysuccinimide

[0026] A certain amount of 1000g L-aspartic acid and 10g H 3 PO 4 Add it to liquid paraffin, heat to 190°C and react for 3 hours, separate the water produced by the reaction with a water separator, cool down to 35°C, and separate the liquid paraffin by suction filtration, wash the solid product with ethanol and distilled water three times respectively, and place at 80°C Dry it in a constant temperature drying oven for 10 hours to obtain light yellow polysuccinimide powder. After testing, the mass average molecular weight of polysuccinimide is 7460, and it is ready for use.

[0027] In the present invention, the test of molecular weight adopts gel chromatography to carry out on Waters510 gel chromatograph, specifically: adopt differential refraction detector, polystyrene is used as standard sample, and chromatographic column adopts PlgelMIXED-B 300 * 7.5, 10 μ m, The temperature is 35°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com