Treatment method of arsenic-containing wastewater in tungsten smelting

A treatment method and wastewater technology, applied in metallurgical wastewater treatment, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of few applications, and achieve the effect of simple process and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

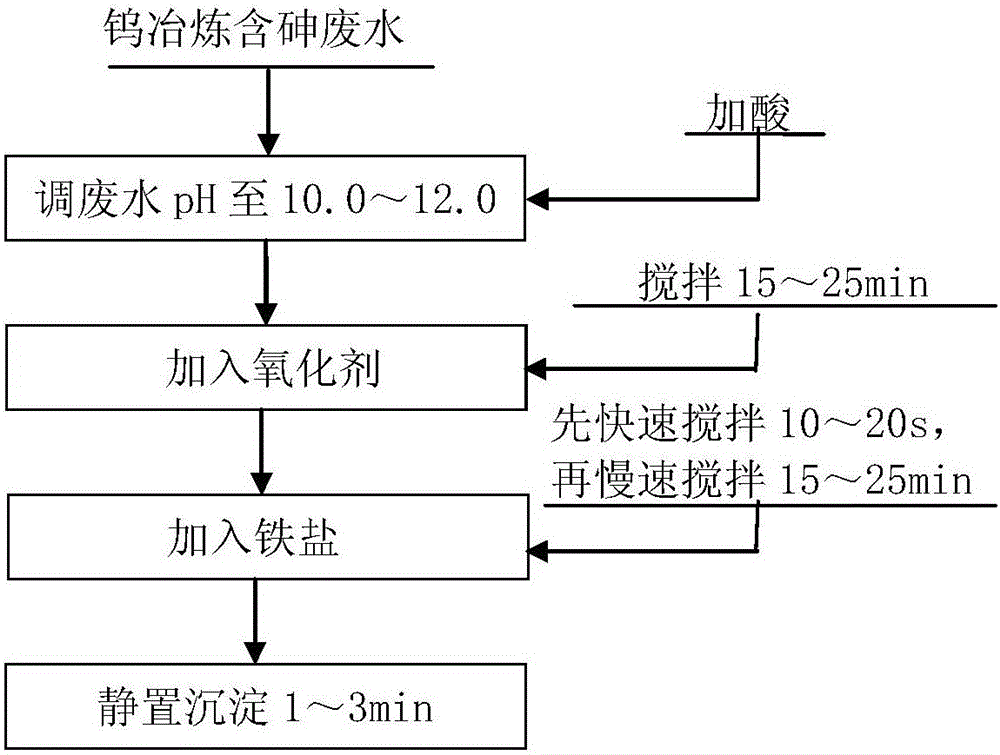

Image

Examples

Embodiment 1

[0033] A tungsten mine selects arsenic-containing wastewater (total arsenic mass concentration is 10.0mg / L), and the treatment steps for the arsenic-containing wastewater are as follows:

[0034] Step 1) Under normal temperature, pretreat the arsenic-containing wastewater generated during the tungsten smelting process, adjust the pH of the wastewater after pretreatment, slowly add sulfuric acid to the wastewater, and adjust the pH of the wastewater to 10.0-12.0;

[0035] Step 2) Add 3.0% hydrogen peroxide to the wastewater in step 1), the concentration of hydrogen peroxide is 0.4g / L, then stir for 15min, the stirring speed is 60r / min;

[0036] Step 3) continue to add 3.3% ferric chloride in the waste water of step 2), the concentration of ferric chloride is 3.2g / L, while adding ferric chloride, carry out rapid stirring, stirring speed is 300r / min, Stirring time is 10s; then carry out slow stirring, stirring speed is 20r / min, stirring time is 15min;

[0037] Step 4) Finally, t...

Embodiment 2

[0040] For a tungsten smelting arsenic-containing wastewater (total arsenic mass concentration is 10.5mg / L), the treatment steps for the arsenic-containing wastewater are as follows:

[0041] Step 1) Under normal temperature, pretreat the arsenic-containing wastewater generated during the tungsten smelting process, adjust the pH of the wastewater after pretreatment, slowly add hydrochloric acid to the wastewater, and adjust the pH of the wastewater to 10.0-12.0;

[0042] Step 2) Add sodium percarbonate to the wastewater in step 1), the concentration of sodium percarbonate is 0.38g / L, then stir for 18min, the stirring speed is 75r / min;

[0043] Step 3) continue to add ferrous chloride in the waste water of step 2), the concentration of ferrous chloride is 0.2g / L, while adding ferrous chloride, carry out rapid stirring, stirring speed is 400r / min, stirring time for 15s; then carry out slow stirring, the stirring speed is 30r / min, and the stirring time is 20min;

[0044] Step 4)...

Embodiment 3

[0047] For a tungsten smelting arsenic-containing wastewater (total arsenic mass concentration is 46.95 mg / L), the treatment steps for the arsenic-containing wastewater are as follows:

[0048] Step 1) Under normal temperature, pretreat the arsenic-containing wastewater generated during the tungsten smelting process, adjust the pH of the wastewater after pretreatment, slowly add nitric acid to the wastewater, and adjust the pH of the wastewater to 10.0-12.0;

[0049] Step 2) Add sodium hypochlorite to the wastewater in step 1), the concentration of sodium hypochlorite is 1.64g / L, then stir for 25min, the stirring speed is 80r / min;

[0050] Step 3) continue to add ferrous sulfate in the waste water of step 2), the concentration of ferrous sulfate is 0.83g / L, while adding ferrous sulfate, carry out rapid stirring, stirring speed is 500r / min, and stirring time is 20s; Carry out slow stirring again, the speed of stirring is 50r / min, and stirring time is 25min;

[0051] Step 4) Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com