Method for producing lactoferrin and lactoperoxidase

A technology of lactoperoxidase and lactoferrin, which is applied in the field of production of lactoferrin and lactoperoxidase, can solve the problems of unsatisfactory recovery rate, unfavorable industrial production, complicated steps and the like, and achieves low difficulty in sewage treatment. , Conducive to industrial application and storage and transportation, the effect of low solution salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

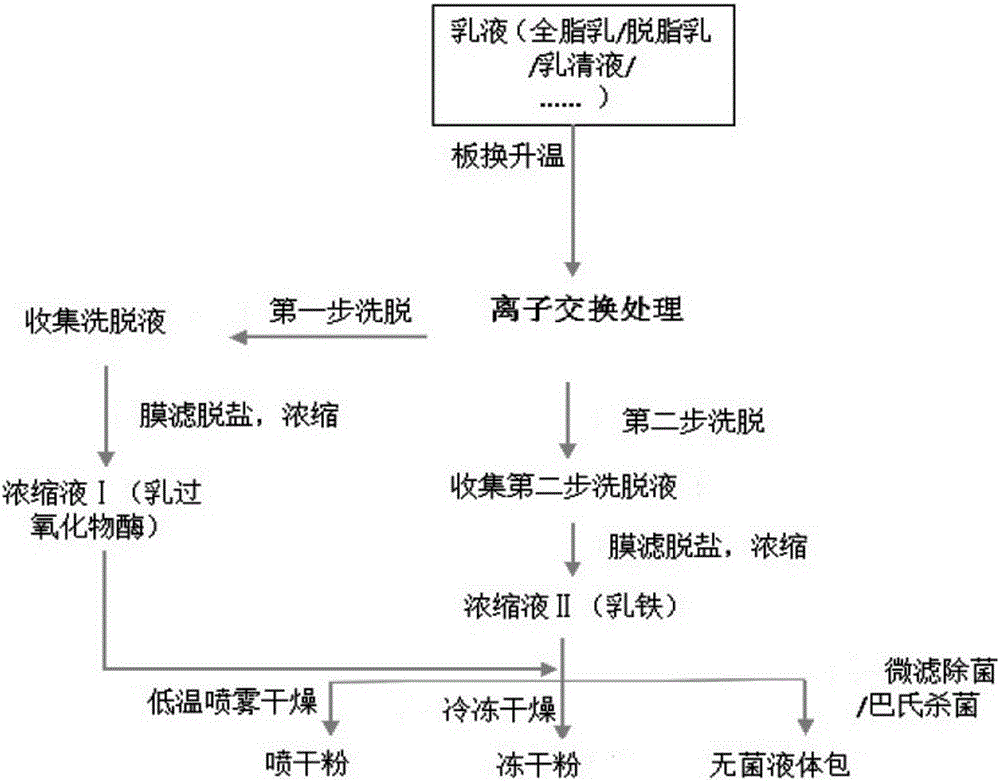

[0063] refer to figure 1 Shown technological process, prepare lactoferrin and lactoperoxidase according to the following steps:

[0064] Take an emulsion (skimmed milk) with a fat content of less than 0.2% and a particle size of less than 8 microns, at a temperature between 4°C and 10°C, and use an ion exchange resin to perform ion exchange treatment on the emulsion in order to peroxidize lactoferrin and lactoferrin The enzyme is adsorbed on the ion exchange resin, the retention time of the milk in the resin column is 2min, and then the emulsion is pushed out with water.

[0065] In the first step of elution, about 4 column volumes of 1% sodium chloride solution are used for elution, and the eluate is collected to obtain a lactoperoxidase salt solution;

[0066] In the second step of elution, about 4 column volumes of 4.5% sodium chloride solution are used for elution, and the eluate is collected to obtain a lactoferrin salt solution;

[0067] Concentrate the eluted lactofer...

Embodiment 2

[0072] refer to figure 1 Shown technological process, prepare lactoferrin and lactoperoxidase according to the following steps:

[0073] Take an emulsion with a fat content of less than 0.5% and a particle size of less than 8 microns, and use an ion exchange resin to perform ion exchange treatment on the emulsion at a temperature between 15°C and 20°C, so that lactoferrin and lactoperoxidase can be adsorbed on the emulsion. On the ion exchange resin, the retention time of milk in the resin column is 2min, and then the emulsion is pushed out with water.

[0074] The first step of elution is carried out by using about 4 column volumes of 1.2% potassium chloride solution to obtain lactoperoxidase salt solution;

[0075] In the second step of elution, about 4 column volumes of 5% potassium chloride solution are used for elution to obtain a lactoferrin salt solution;

[0076] Concentrate the eluted lactoferrin salt solution and lactoperoxidase salt solution by 10 times using a me...

Embodiment 3

[0079] refer to figure 1 Shown technological process, prepare lactoferrin and lactoperoxidase according to the following steps:

[0080] Take a full-fat emulsion with a particle size of less than 8 microns at a temperature between 52 ° C and 55 ° C, and use an ion exchange resin to perform ion exchange treatment on the emulsion so that lactoferrin and lactoperoxidase can be adsorbed to the ion exchange resin Above, the retention time of milk in the resin column is 1min, and then the emulsion is pushed out with water.

[0081] The first step of elution is carried out by using about 4 column volumes of 2.5% sodium chloride solution to obtain lactoperoxidase salt solution;

[0082] In the second step of elution, about 4 column volumes of 10% sodium chloride solution are used for elution to obtain a lactoferrin salt solution;

[0083] Concentrate the eluted lactoferrin salt solution and lactoperoxidase salt solution by 10 times using a membrane with a pore size of 50 kDa, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com