High-temperature resistance modified polyethylene glycol terephthalate

A technology of polyethylene terephthalate and polyethylene terephthalate, which is applied in the field of high-temperature-resistant modified polyethylene terephthalate, and can solve the problems of plastic quality, flame retardancy, and high-temperature resistance The mechanical strength and hardness cannot meet the needs of product use, the production cost restricts the development of polyethylene terephthalate, and the product shrinkage is large, so as to achieve the effects of excellent high temperature resistance, easy processing, and large surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

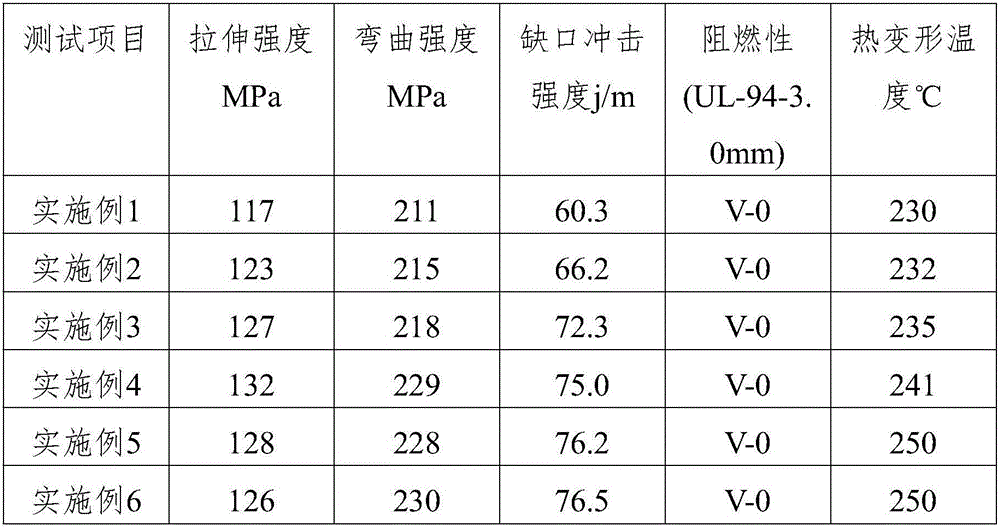

Examples

Embodiment 1

[0018] The invention provides a high-temperature-resistant modified polyethylene terephthalate, which is prepared from the following raw materials in parts by weight: polyethylene terephthalate: 20 parts, cellulose acetate butyrate : 10 parts, polybutadiene rubber: 5 parts, glyceryl monostearate: 1 part, glass microspheres: 2 parts, antioxidant: 2 parts, reinforcing fiber: 3 parts, dibutyl phthalate : 2 parts, azobisisobutyronitrile: 2 parts, oleic acid diethanolamide: 2 parts, fumed silica: 3 parts;

Embodiment 2

[0020] The invention provides a high-temperature-resistant modified polyethylene terephthalate, which is prepared from the following raw materials in parts by weight: polyethylene terephthalate: 50 parts, cellulose acetate butyrate : 20 parts, polybutadiene rubber: 12 parts, glyceryl monostearate: 9 parts, glass microspheres: 6 parts, antioxidant: 8 parts, reinforcing fiber: 5 parts, dibutyl phthalate : 10 parts, azobisisobutyronitrile: 10 parts, oleic acid diethanolamide: 8 parts, fumed silica: 10 parts;

Embodiment 3

[0022] The invention provides a high-temperature-resistant modified polyethylene terephthalate, which is prepared from the following raw materials in parts by weight: polyethylene terephthalate: 25 parts, cellulose acetate butyrate : 12 parts, polybutadiene rubber: 6 parts, glyceryl monostearate: 2 parts, glass microspheres: 4 parts, antioxidant: 3 parts, reinforcing fiber: 3 parts, dibutyl phthalate : 3 parts, azobisisobutyronitrile: 4 parts, oleic acid diethanolamide: 3 parts, fumed silica: 6 parts;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com