Pre-crosslinking swellable profile control agent, preparation method and application

A technology of profile control agent and body expansion type, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high expansion speed, achieve reasonable distribution, high strength, and improve the effect of water absorption profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

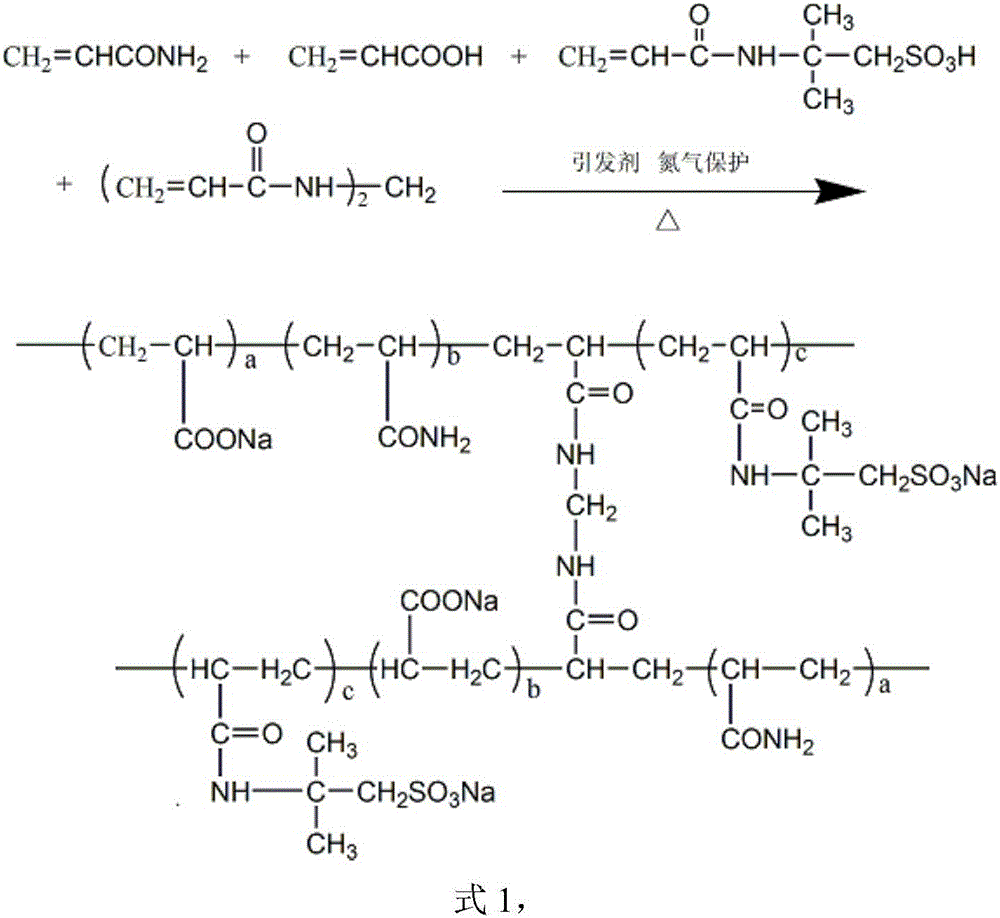

[0032] In terms of parts by mass, the raw materials of the pre-crosslinked bulking profile control agent include: mixed monomers (acrylamide, acrylic acid and 2-acrylamido-2-methylpropanesulfonic acid in a mass ratio of 1.5:2.4:8) 20 parts, 0.01 parts of crosslinking agent (N,N'-methylene bisacrylamide), 3 parts of reinforcing agent (sodium bentonite), 0.02 parts of initiator (ammonium persulfate), a small amount of sodium hydroxide, 80 parts of water .

[0033] The preparation steps of the pre-crosslinked swelling type profile control agent are as follows:

[0034] 1) Add acrylic acid (AA) to 40 parts of water to prepare a solution with a mass concentration of 9.2%, adjust the pH of the solution to 8 with sodium hydroxide, and set aside;

[0035] The enhancer was added to 36 parts of water to prepare a slurry with a mass concentration of 7.7%, and left to stand for 24 hours to obtain a prehydrated enhancer slurry;

[0036] 2) adding acrylamide, 2-acrylamido-2-methylpropanes...

Embodiment 2

[0040] In terms of mass percentage, the raw materials of the pre-crosslinked bulking profile control agent include: mixed monomers (acrylamide, acrylic acid and 2-acrylamido-2-methylpropanesulfonic acid in a mass ratio of 2.1:2:7.5)40 0.05 parts of crosslinking agent (N,N'-methylenebisacrylamide), 5 parts of reinforcing agent (sodium bentonite), 0.01 part of initiator (potassium persulfate), a small amount of sodium hydroxide, and 160 parts of water.

[0041] The preparation steps of the pre-crosslinked swelling type profile control agent are as follows:

[0042] 1) Add acrylic acid (AA) to 100 parts of water to prepare a solution with a mass concentration of 6.45%, adjust the pH of the solution to 9 with sodium hydroxide, and set aside;

[0043]Add the enhancer to 55 parts of water, prepare a slurry with a mass concentration of 8.3%, and let it stand for 24 hours to obtain a prehydrated enhancer slurry;

[0044] 2) adding acrylamide, 2-acrylamido-2-methylpropanesulfonic acid...

Embodiment 3

[0048] In terms of mass percentage, the raw materials of the pre-crosslinked bulking profile control agent include: mixed monomers (acrylamide, acrylic acid and 2-acrylamido-2-methylpropanesulfonic acid at a mass ratio of 1.8:1.5:7.9)30 0.04 parts of crosslinking agent (N,N'-methylenebisacrylamide), 8 parts of reinforcing agent (sodium bentonite), 0.04 parts of initiator (ammonium persulfate), a small amount of sodium hydroxide, and 120 parts of water.

[0049] The preparation steps of the pre-crosslinked swelling type profile control agent are as follows:

[0050] 1) Add acrylic acid (AA) to 60 parts of water to prepare a solution with a mass concentration of 6.27%, adjust the pH of the solution to 9 with sodium hydroxide, and set aside;

[0051] Add the enhancer to 56 parts of water, prepare a slurry with a mass concentration of 12.5%, and let it stand for 24 hours to obtain a prehydrated enhancer slurry;

[0052] 2) adding acrylamide, 2-acrylamido-2-methylpropanesulfonic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com