Degumming method of boehmeria nivea for mulching films

A degumming method and ramie technology are applied in the field of ramie biological degumming technology, which can solve the problems of stagnant fresh hemp degumming technology, low transportation cost, low processing engineering storage cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Raw materials such as raw hemp of ramie mentioned in the present invention, urea, molasses, chitosan, pectinase all are conventional production and can be purchased in the market. The technical solutions provided by the present invention are all carried out at normal temperature (12-35° C.), and the clear water is tap water, river water, well water, etc. at normal temperature and without pollution. The following descriptions are only preferred implementation examples of the present invention, and do not constitute limitations to the present invention.

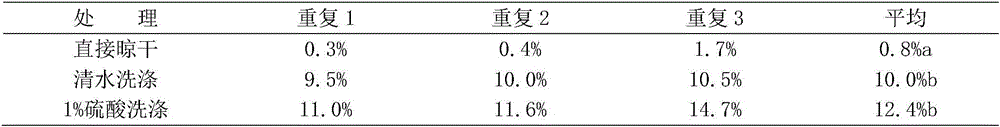

[0022] In this implementation case, the quantitative analysis method of the chemical composition of ramie is carried out with reference to the national standard GB5889-86. The steps are:

[0023]1. In the cement pool, 8kg urea, 3kg molasses, 2kg oxalic acid, 0.3kg calcium chloride, 0.20kg chitosan, 0.25kg pectinase and 0.20kg xylanase were dissolved in 500kg of normal temperature tap water by weight In, stir well.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com