Self-support type building hoisting intelligent medium-voltage power cable and manufacturing method thereof

A power cable, self-supporting technology, applied in the field of self-supporting building hoisting intelligent medium-voltage power cable and its manufacturing, can solve the problems of large outer diameter of combined cable, large cable bending radius, large hoisting load, etc., and achieve long-term operation. Safe and reliable, small partial discharge, uniform electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

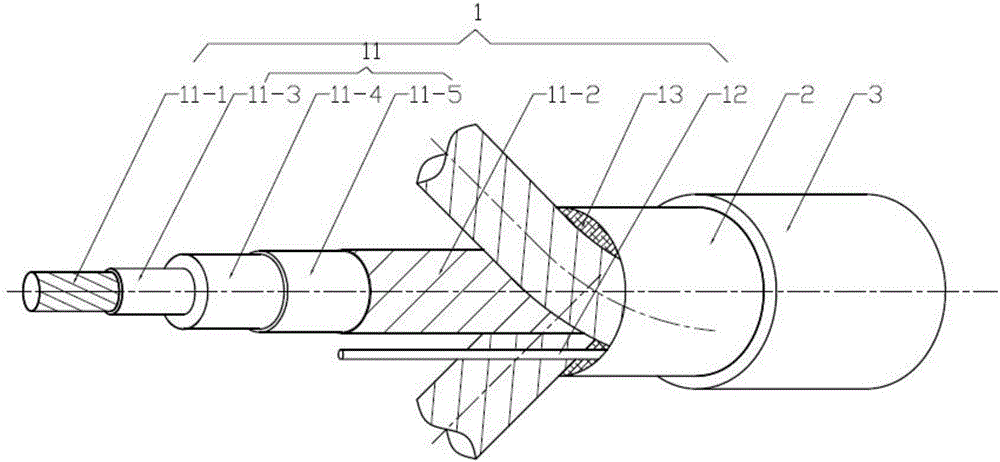

[0020] See figure 1 , a self-supporting intelligent medium-voltage power cable for building hoisting in this embodiment, from the inside to the outside is the cable core 1, the low-smoke and zero-halogen wrapping tight belt 2 and the low-smoke and zero-halogen weather-resistant outer sheath layer 3; The cable core 1 includes three insulated wire cores 11, intelligent control on-line monitoring components 12 and low-smoke and halogen-free filling 13; each insulated wire core 11 is copper-magnesium alloy conductor 11-1, composite insulation layer and copper tape shielding from inside to outside layer 11-2; the composite insulating layer is a three-layer cross-linked co-extruded conductor semi-conductive shielding layer 11-3, cross-linked polyethylene insulating layer 11-4 and insulating semi-conductive shielding layer 11-5; copper-magnesium alloy conductor 11- 1. The magnesium content is 0.01%-0.1%, the resistivity of the conductor at 20°C is ≥95% IACS, and the tensile strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com