Preparation method and application of foamed nickel-based Ni3Se2 nano material

A technology of nanomaterials and nickel foam, which is applied in the field of electrocatalytic material preparation technology and new energy, can solve the problems of inapplicability to large-scale production, complicated preparation process, and expensive electrode materials, and achieves the advantages of rapid and direct transfer and simple preparation process The effect of easy operation and good photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

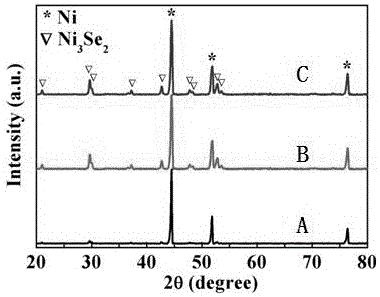

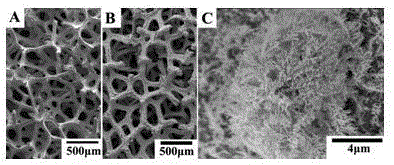

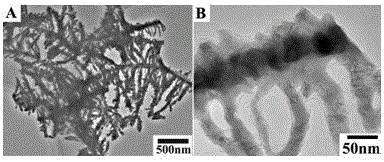

Examples

Embodiment 1

[0037] Step 1: Cut out a piece with a size of 3cm×3cm×1.5mm and a surface density of 300 g m -2 The foamed nickel was cleaned in an ultrasonic cleaner with acetone, hydrochloric acid, acetic acid, deionized water and ethanol respectively;

[0038] Step 2: Use a precision electronic balance to weigh 0.05 mmol (about 0.0055 g) of selenium dioxide into a container; use a pipette gun to measure 42 ml of benzyl alcohol into the container, and magnetically stir to disperse at 25 ° C;

[0039] Step 3: Add the cleaned nickel foam and the prepared mixed solution together into the reaction kettle, seal the reaction kettle, place it in a blast drying oven, heat to 170°C, and react for 13 hours;

[0040] Step 4, after the reaction is over, the reactor is naturally cooled to room temperature, and the Ni 3 Se 2 The nanomaterials were cleaned with deionized water and ethanol, respectively, and dried in a vacuum oven at 40 °C for 8 h to obtain Ni foam-based Ni 3 Se 2 nanomaterials.

Embodiment 2

[0042] Step 1: Cut out a piece with a size of 3cm×3cm×1.5 mm and a surface density of 300 g m-2 The foamed nickel was cleaned in an ultrasonic cleaner with acetone, hydrochloric acid, acetic acid, deionized water and ethanol respectively;

[0043] Step 2, using a precision electronic balance to weigh 0.10 mmol (about 0.0111g) of selenium dioxide into the inner container; using a pipette gun to measure 45ml of benzyl alcohol into the inner container, and magnetic stirring at 25°C to disperse;

[0044] Step 3, add the above-mentioned cleaned foamed nickel and the prepared mixed solution into a 60 ml hydrothermal reaction kettle, seal the hydrothermal reaction kettle, place it in a blast drying oven, heat to 180°C, and react for 15 hours;

[0045] Step 4, after the reaction is over, the hydrothermal reactor is naturally cooled to room temperature, and the Ni 3 Se 2 The nanomaterials were cleaned with deionized water and ethanol, respectively, and dried in a vacuum oven at 50 °C ...

Embodiment 3

[0047] Step 1: Cut out a piece with a size of 3cm×3cm×1.5 mm and a surface density of 300 g m -2 The foamed nickel was cleaned in an ultrasonic cleaner with acetone, hydrochloric acid, acetic acid, deionized water and ethanol respectively;

[0048] Step 2, use a precision electronic balance to weigh 0.15 mmol (about 0.0166g) of selenium dioxide into the inner container; use a pipette gun to measure 48ml of benzyl alcohol into the inner container, and disperse with magnetic stirring at 25°C;

[0049] Step 3, add the above-mentioned cleaned foamed nickel and the prepared mixed solution into a 60 ml hydrothermal reaction kettle, seal the hydrothermal reaction kettle, place it in a blast drying oven, heat to 190°C, and react for 17 hours;

[0050] Step 4, after the reaction is over, the hydrothermal reactor is naturally cooled to room temperature, and the Ni 3 Se 2 The nanomaterials were cleaned with deionized water and ethanol respectively, and dried in a vacuum oven at 70 °C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com