Preparation method of antioxidant

An antioxidant and co-solvent technology, applied in cosmetic preparations, skin care preparations, cosmetics and other directions, can solve problems such as the application limitation of rosemary, and achieve the effects of saving equipment investment, simple equipment investment and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

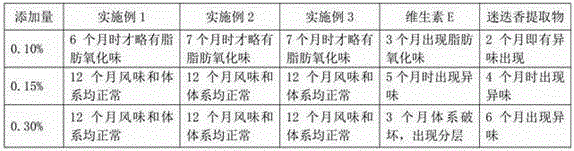

Examples

Embodiment 1

[0020] (1) Take 3g of decaglycerol monooleate and dissolve it in 80g of glycerin at 40°C, then add 6g of rosemary extract, stir and dissolve evenly, then add 8g of deionized water and stir evenly to prepare the water phase;

[0021] (2) Cut the water phase at a speed of 12000rpm, weigh 8g of natural vitamin E, slowly add it to the water phase, and cut it until the average particle size of the emulsion is 0.209μm to obtain the antioxidant product;

[0022] The rosemary extract is prepared according to the following method: take 10 g of rosemary, add 100 g of water, stir and extract at 60 ° C for 1 h, filter to remove residue, and use a PDMS / PTFE composite membrane for pervaporation separation of the filtrate at 10 ° C. Discard the permeate, take the side material that has not passed through the separation membrane and filter it with a ceramic membrane, and concentrate the filtrate by reverse osmosis until the Brix reaches 20%, which is the rosemary extract.

Embodiment 2

[0024] (1) Take 8g of octaglycerol monostearate and dissolve it in 60g of propylene glycol at 60°C, then add 3g of rosemary extract, stir and dissolve evenly, then add 12g of deionized water and stir evenly to prepare the water phase;

[0025] (2) Cut the water phase at 4000rpm, weigh 12g of natural vitamin E, slowly add it to the water phase, and cut until the average particle size of the emulsion is 0.592μm, and then the antioxidant product is obtained.

[0026] Wherein, the rosemary extract is prepared according to the following method: take 10 g of rosemary, add 20 g of water, stir and extract at 40°C for 3 hours, filter to remove residue, and use PDMS / PVDF pervaporation membrane to permeate the filtrate at 20°C Separation by vaporization, discarding the permeate, taking the material that has not passed through the separation membrane and filtering it with a ceramic membrane, and concentrating the filtrate by reverse osmosis until the Brix reaches 40%, which is the rosemary...

Embodiment 3

[0028] (1) Take 2g of decaglycerol decapalmitate and 4g of octaglycerol monooleate, dissolve it in 70g of sorbitol at 50°C, then add 4g of rosemary extract, stir to dissolve evenly, and then add 10g of deionized water Stir evenly to prepare an aqueous phase;

[0029] (2) Cut the water phase at 9000rpm, weigh 10g of natural vitamin E, slowly add it to the water phase, and cut until the average particle size of the emulsion is 0.492μm, to obtain the antioxidant product.

[0030] Wherein, the rosemary extract is prepared according to the following method: take 10 g of rosemary, add 60 g of water, stir and extract at 50 ° C for 2 h, filter to remove residue, and carry out pervaporation of the filtrate at 15 ° C with a PDMS / PAN composite membrane Separation, discarding the permeate, taking the side material that has not passed through the separation membrane and filtering it with a ceramic membrane, and the filtrate is concentrated by reverse osmosis until the Brix reaches 30%, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com