Full-spectral response type ammonium tungsten bronze-titanium dioxide composite photocatalyst

A technology of titanium dioxide and tungsten bronze, which is applied in the field of photocatalytic materials, can solve the problem of not considering the photocatalytic effect, etc., and achieve the effects of improved catalytic activity, low equipment requirements, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

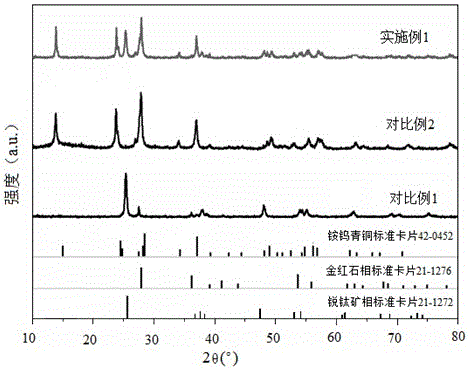

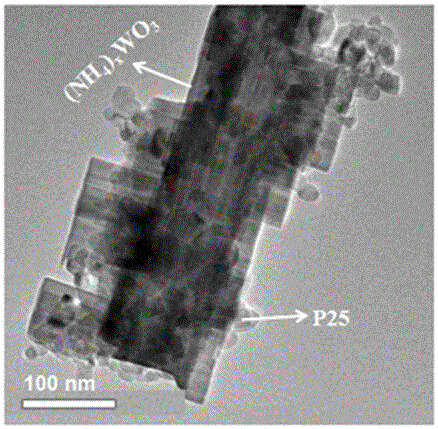

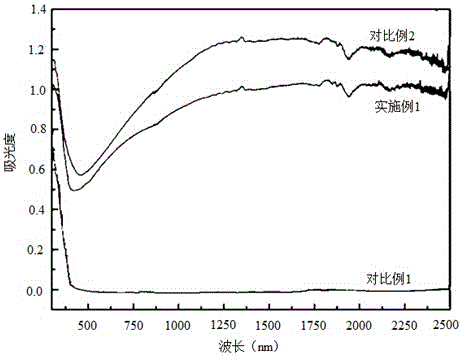

[0023] Weigh 0.25g of ammonium paratungstate, add it to 40mL of ethylene glycol, and stir magnetically at 190°C for 60 minutes to fully dissolve to obtain a clear and transparent liquid; after the liquid is cooled to room temperature, add 0.4g of nano-titanium dioxide with photocatalytic activity, after ultrasonic dispersion Stir for 100 minutes to obtain a suspension; add 20 mL of acetic acid to the suspension, stir for 30 minutes to obtain a mixed liquid, transfer the mixed liquid to a hydrothermal kettle, and conduct a hydrothermal reaction at a temperature of 200 °C for 40 hours; Ionized water and ethanol were used to centrifuge and wash the precipitate respectively, and dry to obtain the ammonium tungsten bronze-titanium dioxide composite photocatalyst. The X-ray diffraction spectrum of the photocatalyst, such as figure 1 as shown, figure 1 It shows that the X-ray diffraction peak of the photocatalyst is composed of the diffraction peaks of titanium dioxide and ammonium ...

Embodiment 2

[0041] Add 0.1g of ammonium tungstate to 20mL of ethylene glycol, stir magnetically at 80°C for 90min, fully dissolve to obtain a clear and transparent liquid; add 0.1g of P25 commercial titanium dioxide powder after cooling to room temperature, and stir for 20min after ultrasonic dispersion to obtain a suspension Turbid liquid; add 10mL of acetic acid to the suspension and stir for 10min to obtain a mixed liquid, transfer the mixed liquid to a hydrothermal kettle, and conduct a hydrothermal reaction at 240°C for 10h; successively wash with deionized water and ethanol by centrifugation The precipitate was dried to obtain ammonium tungsten bronze-titanium dioxide composite photocatalyst.

Embodiment 3

[0043] Add 1.0g of ammonium metatungstate to 80mL of ethylene glycol, stir magnetically at 200°C for 75 minutes, and fully dissolve to obtain a clear and transparent liquid; after cooling to room temperature, add 1.0g of nano-titanium dioxide with photocatalytic activity, and stir after ultrasonic dispersion 60min to obtain a suspension; add 80mL of acetic acid to the suspension and stir for 60min to obtain a mixed liquid, transfer the mixed liquid to a hydrothermal kettle, and conduct a hydrothermal reaction at 160°C for 72h; sequentially use deionized water and The precipitates were centrifuged and washed with ethanol, and dried to obtain the ammonium tungsten bronze-titanium dioxide composite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com