Functional modification method for graphene oxide

A technology of ene function and oxidized stone, which is applied in the field of functional modification of graphene oxide, can solve the problems of the influence of active metal stability, poor hydrophilicity and lipophilicity of graphene, and inability to obtain active metals, etc., and achieves simple process and easy operation Simple, high-yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

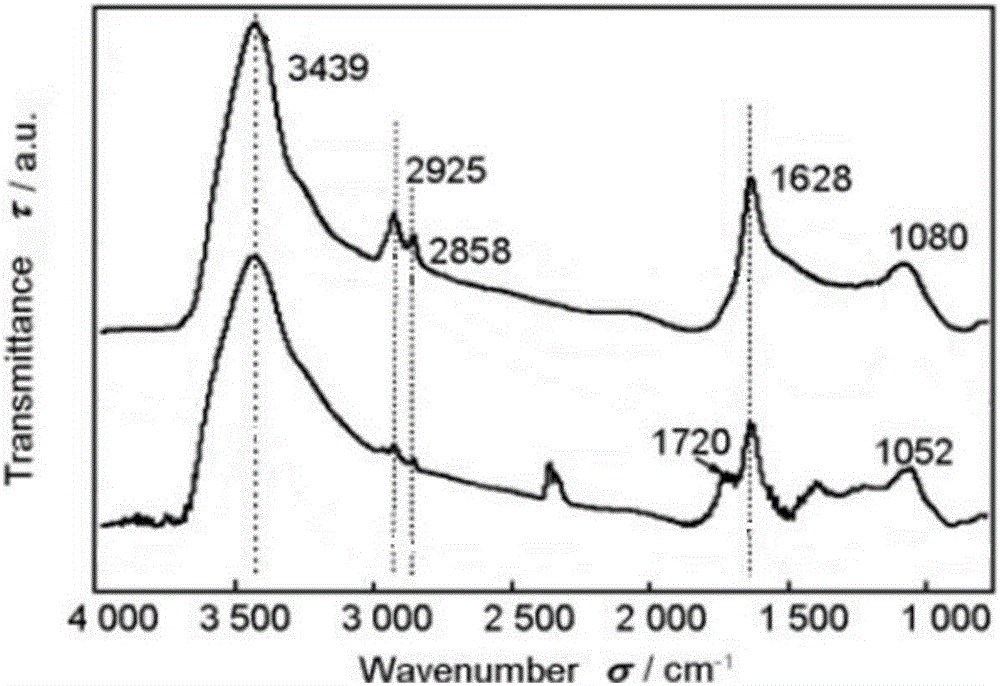

[0043] Step 1: According to the structural characteristics of functional groups of graphene oxide (GO), design grafted amine groups on its surface or edge.

[0044] Step 2: Prepare a graphene oxide aqueous solution with a concentration of 3 mg / mL, and place it in a 3-neck flask for ultrasonication and stirring until it becomes a clear solution.

[0045] Step 3: According to the designed amine functional group, the modifier ethylenediamine is selected, and the ethylenediamine is slowly dropped into the graphene oxide solution, stirred and refluxed for a period of time, wherein the mass ratio of ethylenediamine to graphene oxide is 1: 10. Control the reaction temperature to 40°C, the dropping rate to 20 drops / min, and the reflux time to 4 hours to obtain an amine-modified graphene oxide solution.

[0046] Step 4: Centrifuge the amine-modified graphene oxide solution at a speed of 5000 r / min for 20 minutes, and filter to obtain a gel-like product of amine-modified graphene oxide....

Embodiment 2

[0052] Step 1: According to the functional group structure characteristics of graphene oxide itself, design the grafted amide groups on its surface or edge.

[0053] Step 2: Prepare a graphene oxide aqueous solution with a concentration of 8 mg / mL, and place it in a 3-necked flask with ultrasonic waves and stir until it becomes a clear solution.

[0054] Step 3: According to the designed amide functional group, the modifier acetamide is selected, and the acetamide is slowly dropped into the graphene oxide solution, stirred and refluxed for a period of time, wherein the mass ratio of acetamide to graphene oxide is 1:15, and the control The reaction temperature was 60° C., the dropping rate was 35 drops / min, and the reflux time was 3 hours to obtain an amido-modified graphene oxide solution.

[0055] Step 4: centrifuge the amido-modified graphene oxide solution at a speed of 4000r / min for 30min, and filter to obtain a gel-like product of amido-modified graphene oxide.

[0056] ...

Embodiment 3

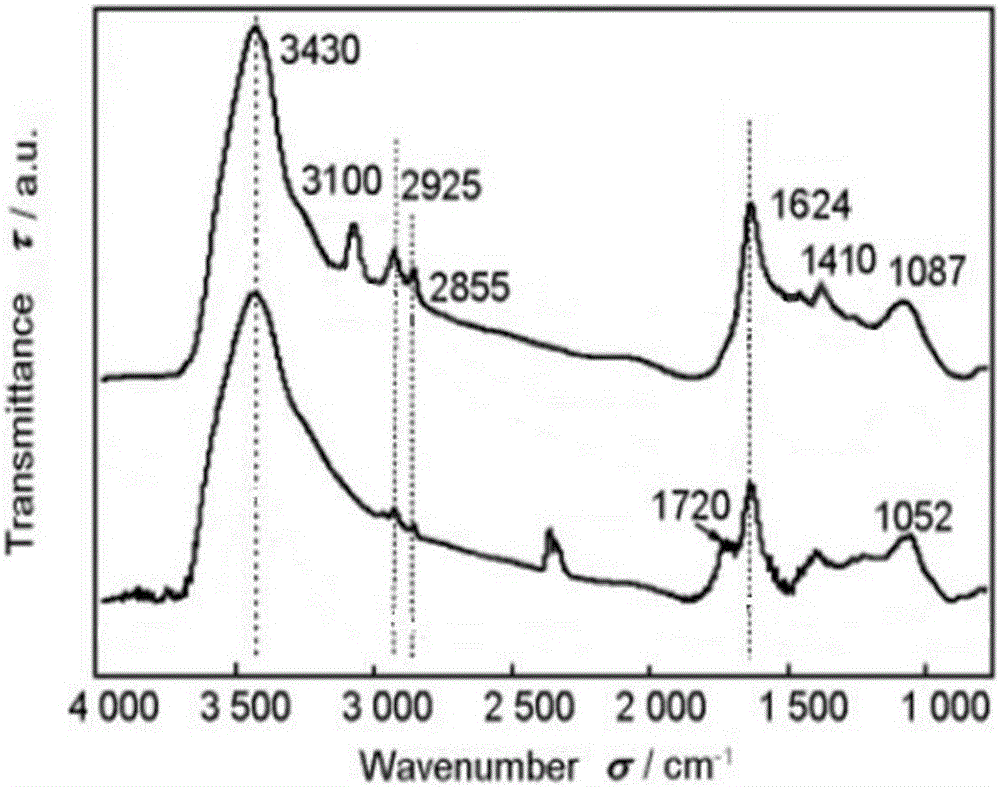

[0060] Step 1: According to the structural characteristics of functional groups of graphene oxide itself, it is designed to graft epoxy groups on its surface or edge.

[0061] Step 2: Prepare a graphene oxide aqueous solution with a concentration of 0.5 mg / mL, and place it in a 3-necked flask with ultrasonic waves and stir until it becomes a clear solution.

[0062] Step 3: According to the design of the epoxy functional group, the modifier ethylene oxide was selected, and the ethylene oxide was slowly dropped into the graphene oxide solution, stirred and refluxed for a period of time, wherein the mass of ethylene oxide and graphene oxide The ratio is 1:20, the reaction temperature is controlled at 20°C, the dropping rate is 10 drops / min, and the reflux time is 5 hours to obtain an epoxy-modified graphene oxide solution.

[0063] Step 4: Centrifuge the epoxy-modified graphene oxide solution at a high speed of 6000 r / min for 10 minutes, and filter to obtain a gel-like product o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com