Preparation of castor oil-based coating material and application of castor oil-based coating material in controlled-release fertilizers

A technology of coating materials and coated controlled-release fertilizers, which is applied in the field of slow-release fertilizers, can solve problems such as difficult product separation, high catalyst prices, and unfavorable recycling, and achieve good chemical stability, high reactivity, and precise nutrients. The effect of controlled release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

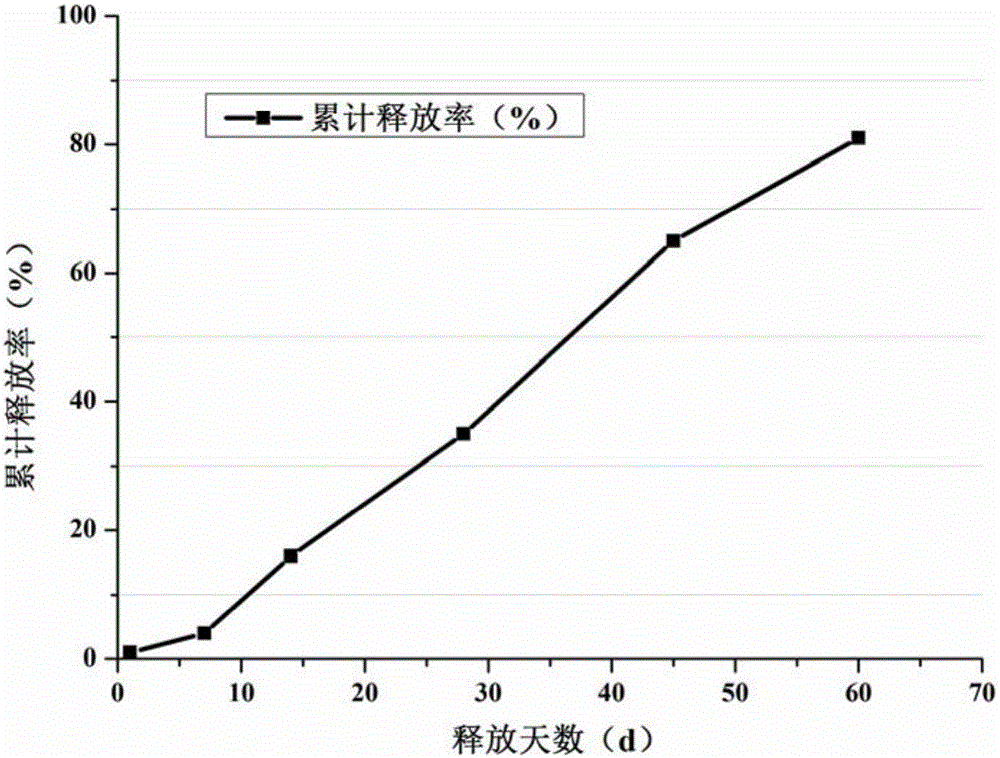

Embodiment 1

[0054] 1. Preparation of coating material based on modified castor oil

[0055] (1) In parts by weight, add 70 parts of castor oil, 7 parts of formic acid, and 0.3 parts of concentrated phosphoric acid (85wt%) into a three-necked flask, keep the temperature in the water bath at 40°C, slowly add 22.7 parts of 30wt% hydrogen peroxide solution dropwise, and the hydrogen peroxide is added dropwise Afterwards, it was raised to 60°C, and after constant temperature reaction for 4 hours, the water phase was removed by liquid separation to obtain a crude product. The crude product was washed with 1wt% sodium hydroxide aqueous solution until pH = 7, and finally the washed material was vacuum-treated at 80°C. Distillation and dehydration under reduced pressure for 1.5h at a temperature of 0.09-0.1MPa to obtain epoxy castor oil.

[0056] According to GB / T1677-2008 standard, the epoxy value of epoxy castor oil is 3.25%.

[0057] According to the GB / T 5532-2008 standard, the iodine value o...

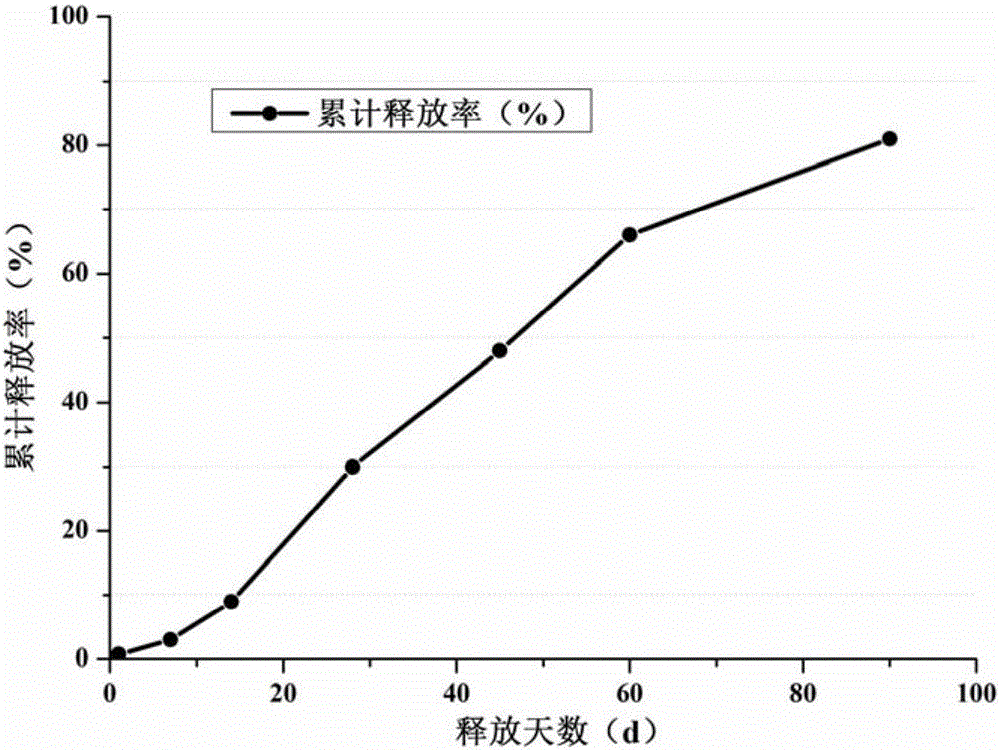

Embodiment 2

[0065] 1. Preparation of coating material based on modified castor oil

[0066] (1) In parts by weight, add 70 parts of castor oil, 7 parts of formic acid, and 0.3 parts of concentrated phosphoric acid (85wt%) into a three-necked flask, keep the temperature in the water bath at 40°C, slowly add 22.7 parts of 30wt% hydrogen peroxide solution dropwise, and the hydrogen peroxide is added dropwise Afterwards, it was raised to 60°C, and after constant temperature reaction for 4 hours, the water phase was removed by liquid separation to obtain a crude product. The crude product was washed with 1wt% sodium hydroxide aqueous solution until pH = 7, and finally the washed material was vacuum-treated at 80°C. Distillation and dehydration under reduced pressure for 1.5h at a temperature of 0.09-0.1MPa to obtain epoxy castor oil.

[0067] According to GB / T1677-2008 standard, the epoxy value of epoxy castor oil is 3.25%.

[0068] According to GB / T 5532-2008 standard, the iodine value of ep...

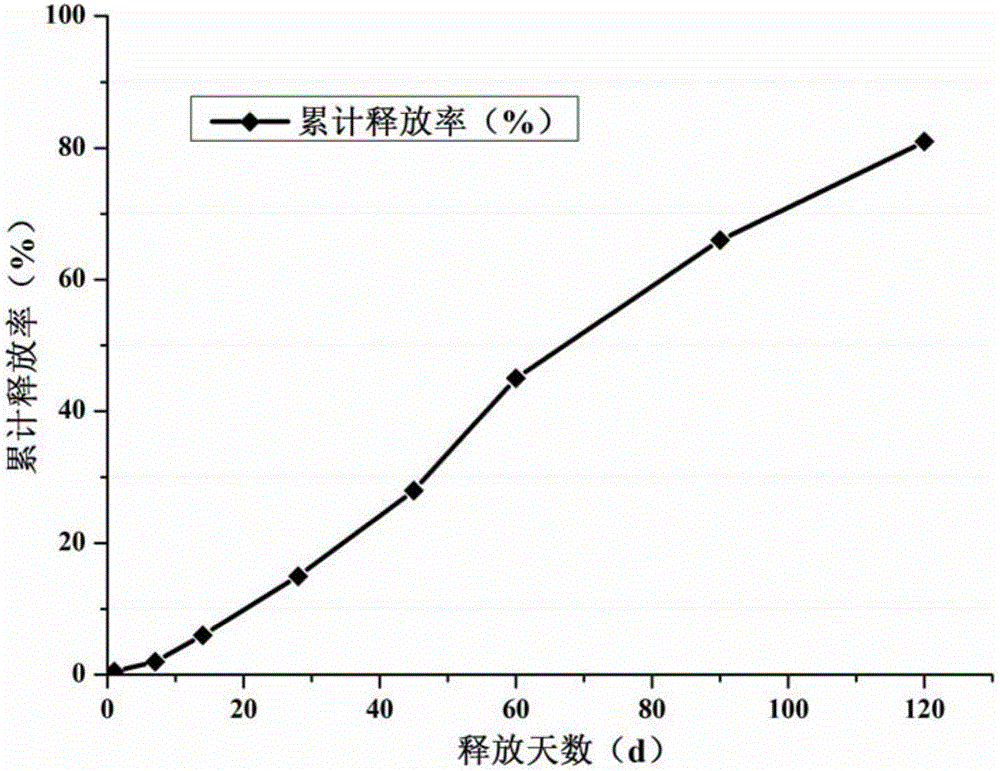

Embodiment 3

[0076] 1. Preparation of coating material based on modified castor oil

[0077] (1) In parts by weight, add 70 parts of castor oil, 7 parts of formic acid, and 0.3 parts of concentrated phosphoric acid (85wt%) into a three-necked flask, keep the temperature in the water bath at 40°C, slowly add 22.7 parts of 30wt% hydrogen peroxide solution dropwise, and the hydrogen peroxide is added dropwise Afterwards, it was raised to 60°C, and after constant temperature reaction for 4 hours, the water phase was removed by liquid separation to obtain a crude product. The crude product was washed with 1wt% sodium hydroxide aqueous solution until pH = 7, and finally the washed material was vacuum-treated at 80°C. Distillation and dehydration under reduced pressure for 1.5h at a temperature of 0.09-0.1MPa to obtain epoxy castor oil.

[0078] According to GB / T1677-2008 standard, the epoxy value of epoxy castor oil is 3.25%.

[0079] According to GB / T 5532-2008 standard, the iodine value of ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com