High-temperature-resistant gelling agent in acid liquid and method for preparing high-temperature-resistant gelling agent

A gelling agent and high temperature resistant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost and poor high temperature resistance, and achieve the effects of stable performance, convenient construction and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

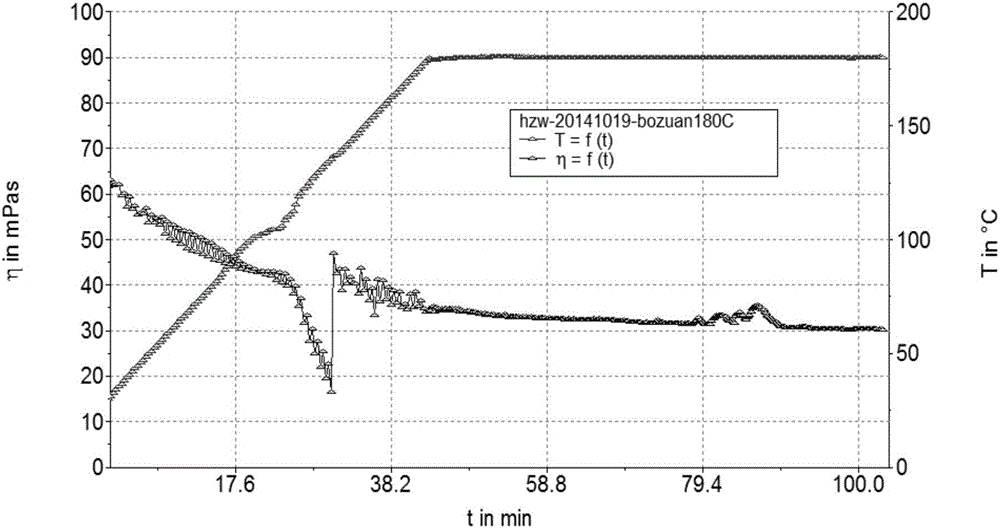

Image

Examples

Embodiment 1

[0024] (1) Prepare reaction mother liquor: dissolve 66g of acrylamide monomer, 75g of acryloyloxyethyltrimethylammonium chloride monomer (80% aqueous solution), 2g of acrylic acid into 300g of deionized water, stir evenly, and then add Na 2 CO 3 Adjust the pH value of the solution to a pH value of 11, stir evenly to obtain a reaction mother liquor, and place the mother liquor into a polymerization device;

[0025] (2) When the temperature of the mother liquor is 8°C, feed high-purity N into the mother liquor 2 ;

[0026] (3) Polymerization reaction: add 0.11g azobisisobutylimidazoline hydrochloride, 0.03g sodium formate, 0.06g potassium persulfate, 0.06g sodium bisulfite, 0.03g three Pentasodium ethylene tetraamine pentaacetate, react fully for 1 hour, then keep warm for 3 hours;

[0027] (4) The polymer obtained after the polymerization reaction in step (3) was taken out and granulated, dried at 60° C. for 5 hours, and pulverized to make a gelling agent.

Embodiment 2

[0029] (1) Prepare reaction mother liquor: dissolve 50g of acrylamide monomer, 56.7g of acryloyloxyethyltrimethylammonium chloride monomer (80% aqueous solution), 5g of itaconic acid into 186.5g of deionized water, and stir Uniformly, then add Na 2 CO 3 Adjust the pH value of the solution to a pH value of 12, stir evenly to obtain a reaction mother liquor, and place the mother liquor into a polymerization device;

[0030] (2) When the temperature of the mother liquor is 8°C, feed high-purity N into the mother liquor 2 ;

[0031] (3) Polymerization reaction: Add 0.07g azobisisobutyronitrile, 0.03g sodium formate, 0.07g potassium persulfate, 0.07g sodium bisulfite, 0.01g ethylenediammonium tetraacetic acid to the mother liquor in step (2) successively , fully reacted for 1 hour, and then kept warm for 3 hours;

[0032] (4) The polymer obtained after the polymerization reaction in step (3) was taken out and granulated, dried at 60° C. for 5 hours, and pulverized to make a gel...

Embodiment 3

[0034] (1) Preparation of reaction mother liquor: dissolve 38.5g of acrylamide monomer, 43.7g of acryloyloxyethyltrimethylammonium chloride monomer (80% aqueous solution), and 10g of acrylic acid into 155g of deionized water, and stir evenly. Then add Na 2 CO 3 Adjust the pH value of the solution to a pH value of 12, stir evenly to obtain a reaction mother liquor, and place the mother liquor into a polymerization device;

[0035] (2) When the temperature of the mother liquor is 8°C, feed high-purity N into the mother liquor 2 ;

[0036] (3) Polymerization reaction: add 0.06g azobisisobutylimidazoline hydrochloride, 0.02g sodium formate, 0.04g potassium persulfate, 0.04g sodium bisulfite, 0.01g ethyl alcohol successively in the mother liquor in step (2) Diammonium tetraacetic acid, fully reacted for 1 hour, then kept warm for 3 hours;

[0037] (4) The polymer obtained after the polymerization reaction in step (3) was taken out and granulated, dried at 60° C. for 5 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com