Purple sweet potato steeping wine and production method thereof

A production method and technology for soaking wine, applied in the field of food processing, can solve the problems of anthocyanin biodegradation damage, long product processing cycle, complex processing technology and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

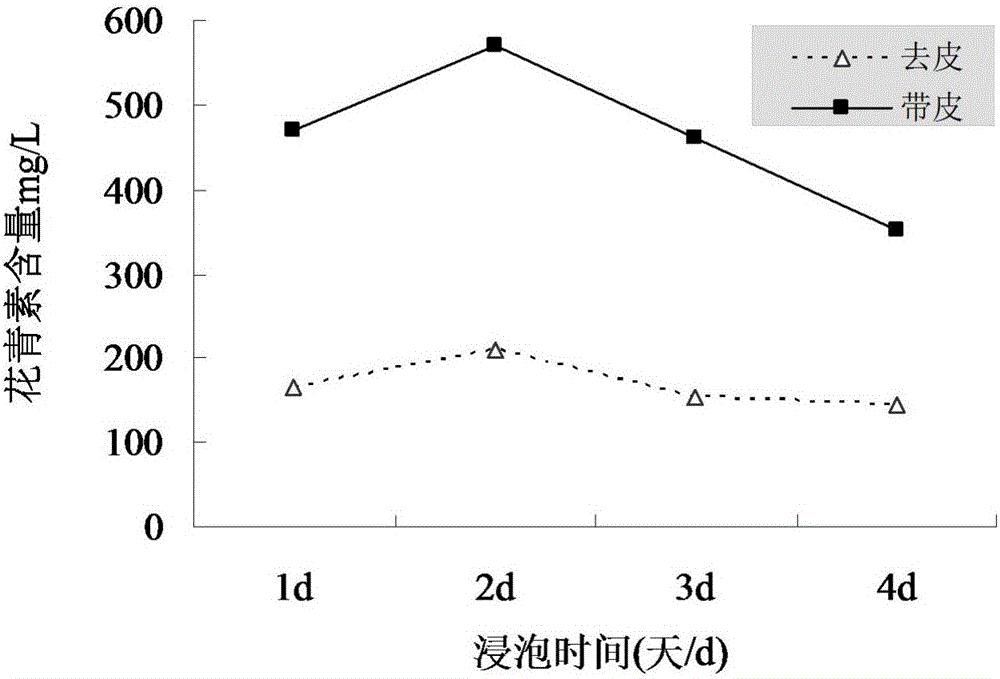

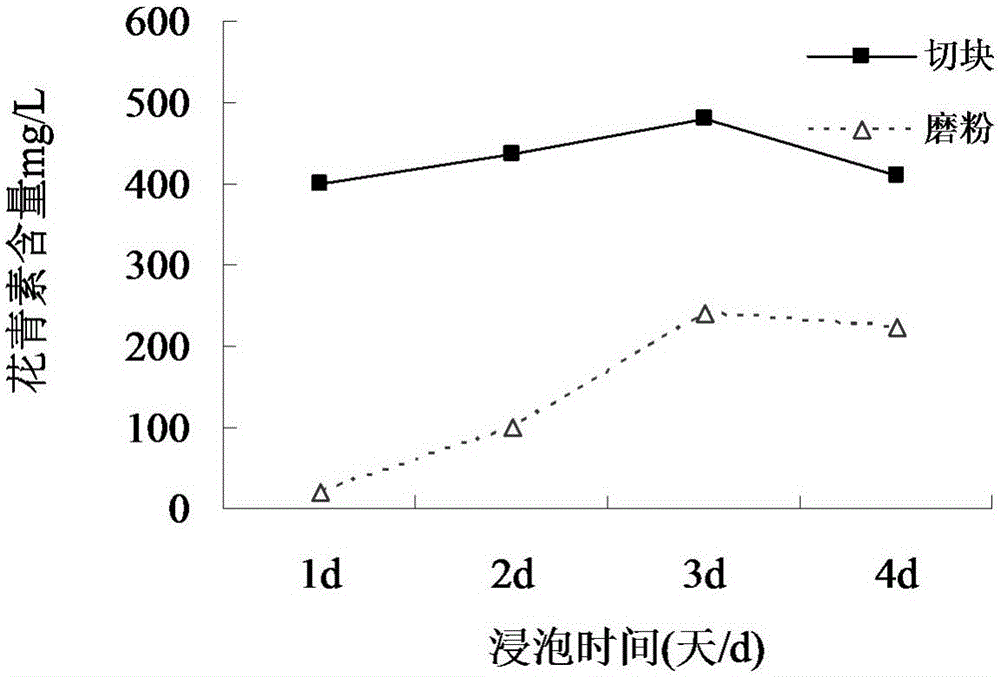

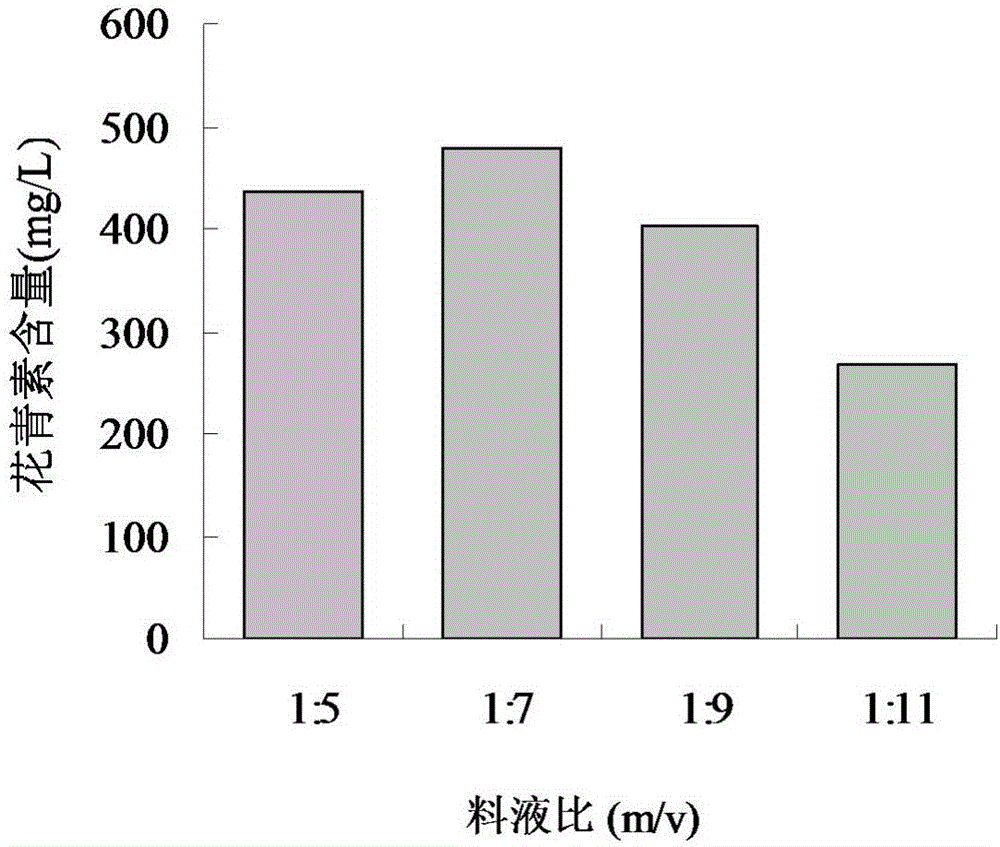

Method used

Image

Examples

Embodiment 1

[0121] Embodiment 1: Production of purple sweet potato soaked wine

[0122] The implementation steps of this embodiment are as follows:

[0123] A. Purple potato pretreatment

[0124] Wash and drain the fresh purple sweet potato, remove the deteriorated skin and potato meat tissue, then cut the purple sweet potato with skin into a size of about 10cm 3 The left and right blocks are put into deionized water for slight heat-fixing treatment (material temperature 60-70°C);

[0125] B. Alcohol reduction

[0126] Calculate the amount of water to be added according to the following formula:

[0127] Volume of base wine × alcohol content of base wine = volume of reduced alcohol × alcohol content of reduced alcohol

[0128] Add the calculated amount of water to Wuliangye Luzhou-flavor distilled liquor base liquor, reduce the alcohol content of the base liquor to 40°, and obtain a pretreated base liquor;

[0129] C. Pre-soak

[0130]According to the ratio of purple potato in grams...

Embodiment 2

[0136] Embodiment 2: produce purple sweet potato soaked wine

[0137] The implementation steps of this embodiment are as follows:

[0138] A. Purple potato pretreatment

[0139] Wash and drain the fresh purple sweet potato, remove the deteriorated skin and potato meat tissue, then crush the peeled purple sweet potato into purple sweet potato powder with a particle size of 80 mesh, and then carry out dry steaming and micro-heating treatment (material temperature 60-70 ℃);

[0140] B. Alcohol reduction

[0141] Calculate the amount of water to be added according to the following formula:

[0142] Volume of base wine × alcohol content of base wine = volume of reduced alcohol × alcohol content of reduced alcohol

[0143] Add the calculated amount of water to Luzhou Laojiao Tequ Luzhou-flavor distilled liquor base liquor, reduce the alcohol content of the base liquor to 40°, and obtain a pretreated base liquor;

[0144] C. Pre-soak

[0145] According to the ratio of purple sw...

Embodiment 3

[0151] Embodiment 3: produce purple sweet potato soaked wine

[0152] The implementation steps of this embodiment are as follows:

[0153] A. Purple potato pretreatment

[0154] Wash and drain the fresh purple sweet potato, remove the deteriorated skin and potato flesh tissue, then cut the unpeeled purple sweet potato into a size of about 27cm 3 The purple sweet potato pieces are then dry-steamed and slightly heat-fixed (material temperature 60-70°C);

[0155] B. Alcohol reduction

[0156] Calculate the amount of water to be added according to the following formula:

[0157] Volume of base wine × alcohol content of base wine = volume of reduced alcohol × alcohol content of reduced alcohol

[0158] Add the calculated amount of water to Jiannanchun Luzhou-flavor distilled liquor base liquor, reduce the alcohol content of the base liquor to 40°, and obtain a pretreated base liquor;

[0159] C. Pre-soak

[0160] According to the ratio of purple potato in grams to the pretrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com