Solar selective absorption composite coating

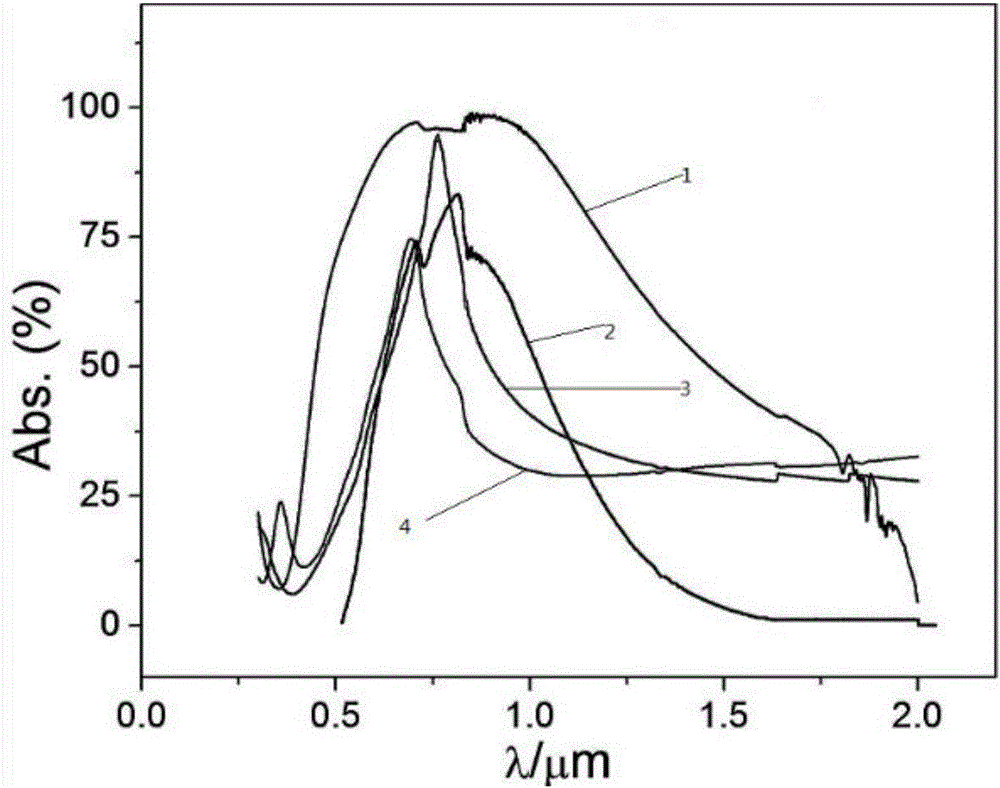

A selective absorption and composite coating technology, applied in solar thermal power generation, coatings, solar thermal devices, etc., can solve the problems of low radiation loss, coating absorption efficiency loss, emissivity increase, etc., to achieve good repeatability and reliability Controllability, simple and convenient operation, excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Instrument preparation

[0019] A magnetron sputtering apparatus model JGP500A, equipped with three Φ75mm permanent magnet magnetron targets, with a maximum sputtering power of 500W; a four-station sample turntable with revolution function, which can realize co-sputtering of three targets Experiment; samples can be heated or water-cooled, the maximum temperature can reach 700°C, and the heating rate can be adjusted from 10°C / min to 50°C / min, which is suitable for preparing films of various materials; the vacuum system is equipped with a 2XZ- 8 (8L / S) mechanical pump and FF-200 / 1200 turbo molecular pump, the highest vacuum degree can reach 7.0×10 -6 Pa.

[0020] Material preparation

[0021] The sputtering targets are Al, 99.99wt% Ag and 99.9wt% Ta with a purity of 99.9wt%, and the diameters are all 75mm; the substrate is a polished metal Cu sheet.

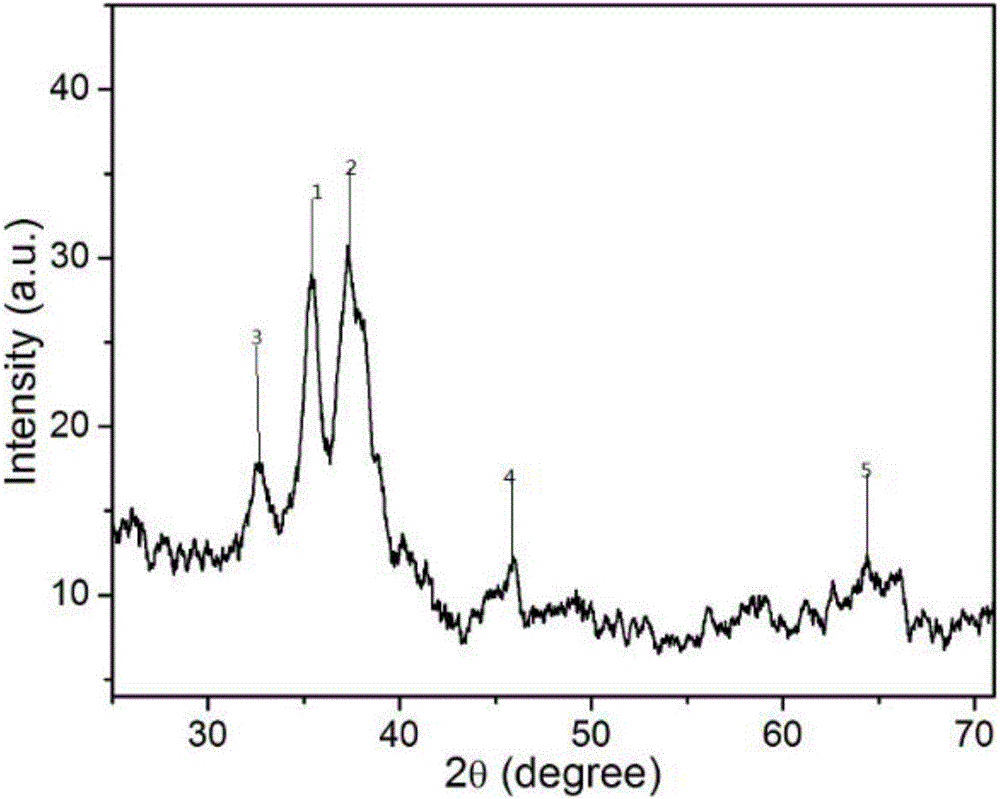

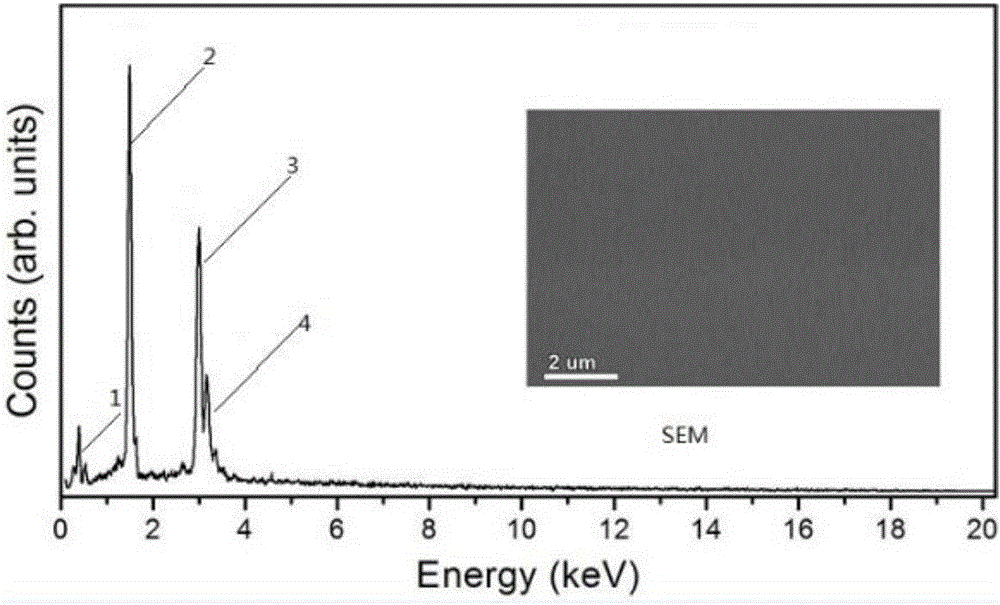

[0022] Coating preparation: Two sets of identical nano-multilayer gradient solar spectrum selective absorption coatings...

Embodiment 2

[0031] According to the method described in Example 1, the nanometer multilayer gradient solar spectrum selective absorption coating is prepared, wherein when the absorption layer is deposited, three layers of gradient absorption layers are selected: take AlN-Ag as a deposition period, set the period value to 3, select Determine the ratio of the sub-layers, deposit the AlN layer and the Ag layer sequentially according to the single-layer absorption layer deposition method, and the deposited three-layer gradient film absorption layers are AlN20nm-Ag5nm / AlN30nm-Ag5nm / AlN40nm-Ag5nm respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com