Ethyl cellulose drug-loading nanofiber membrane and preparation method and application thereof

A technology of ethyl cellulose and nanofiber membranes, which is applied in the fields of medical formula, fiber chemical characteristics, drug delivery, etc., can solve the problems of side effects, ulcers, bleeding, gastrointestinal irritation, etc., and achieve easy operation and prolonged administration time , the effect of mild experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Weigh 0.402 g of EC solid powder with a balance and dissolve it in 2 mL of hexafluoroisopropanol.

[0035] (2) Add 0.04 g of the ketoprofen drug to the above solution and make it completely dissolved, and stir for 48 hours with a magnetic stirrer until the two are completely dissolved in the solvent and mixed uniformly.

[0036] (3) Put 5mL of the prepared spinning solution into the electrospinning device, adjust the spinning parameters for electrospinning, the spray flow rate is 0.3mL / h, the static voltage is 13kV, the receiving distance is 15cm, and the ambient temperature The temperature is 25°C, the humidity is 40-50%, and the spinning time is 5 hours; the collected fiber membranes are placed in a vacuum drying box and dried at room temperature for 24 hours to obtain ethyl cellulose drug-loaded nanofiber membranes.

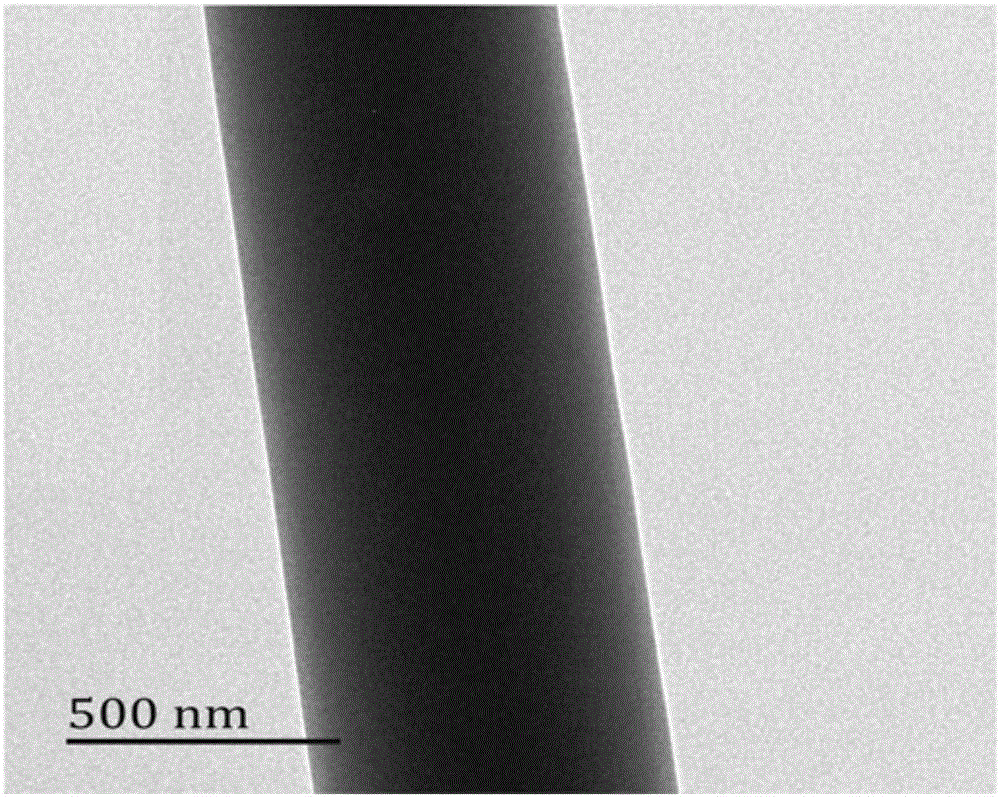

[0037] (4) Collect a few nanofibers with a copper mesh during the spinning process, dry the collected nanofibers at room temperature for 24 hours, and the...

Embodiment 2

[0039] (1) Weigh 0.601 g of EC solid powder with a balance and dissolve it in 3 mL of hexafluoroisopropanol.

[0040] (2) Add 0.06 g of the ketoprofen drug to the above solution and make it completely dissolved, and stir for 48 hours with a magnetic stirrer until the two are completely dissolved in the solvent and mixed uniformly.

[0041] (3) Put 3mL of the configured spinning solution into the electrospinning device, adjust the spinning parameters for electrospinning, the spray flow rate is 0.2mL / h, the static voltage is 12kV, the receiving distance is 17cm, and the ambient temperature The temperature is 25°C, the humidity is 40-50%, and the spinning time is 6h.

[0042] (4) Put the collected nanomembrane into a vacuum drying box and dry at room temperature for 24 hours to obtain an ethylcellulose drug-loaded nanofiber membrane.

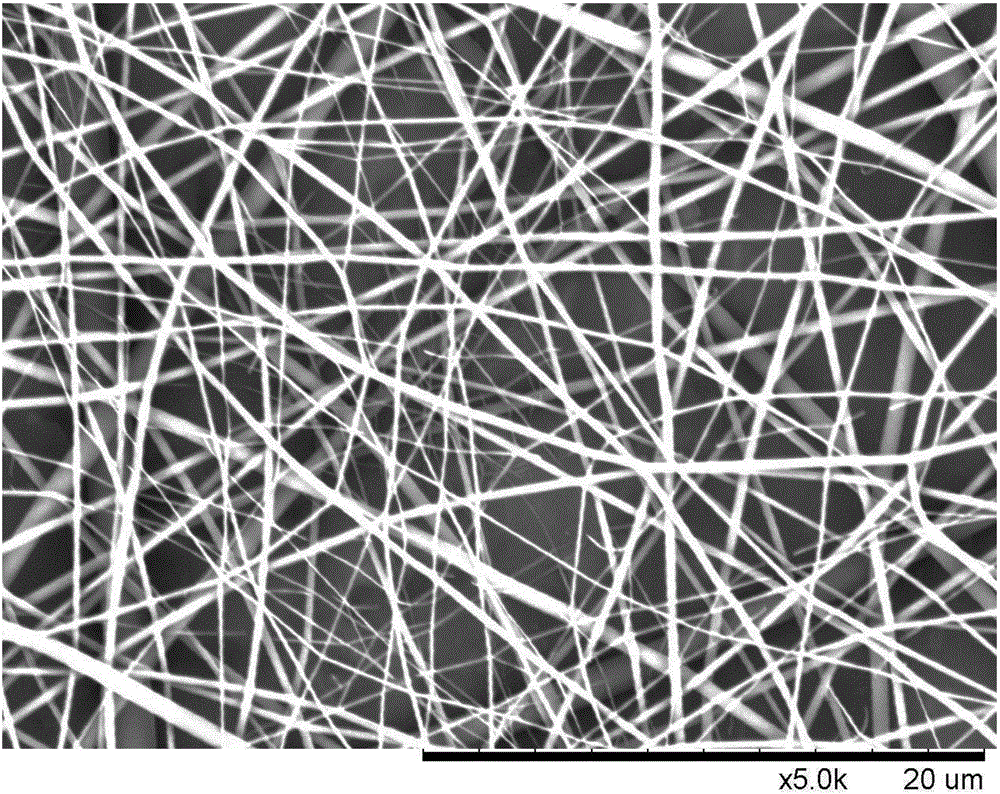

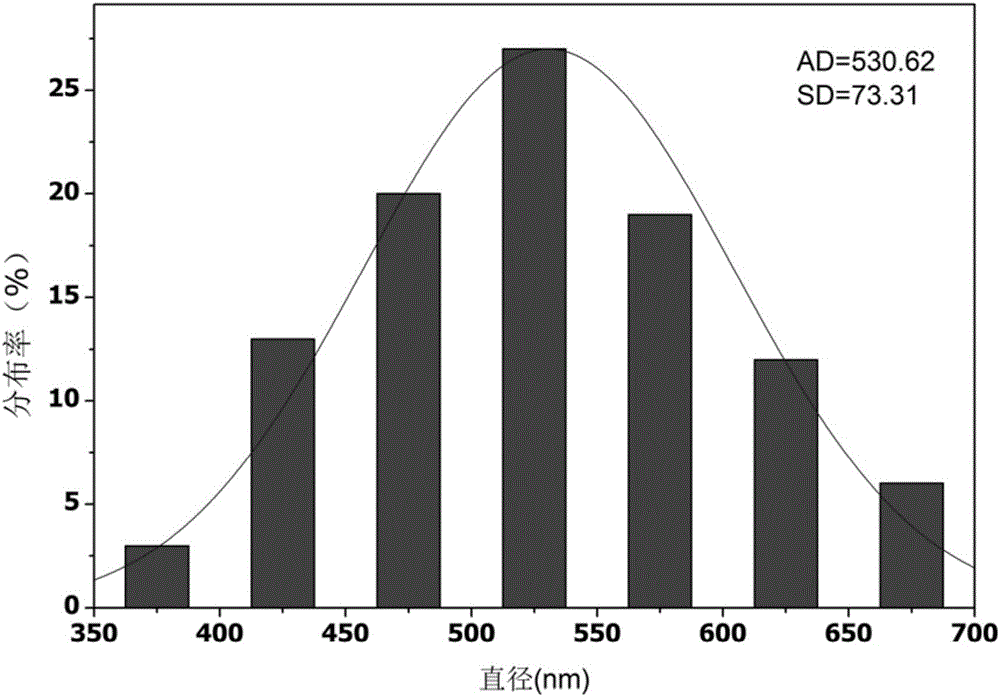

[0043] (5) SEM characterization of ethyl cellulose drug-loaded nanofiber membrane Figure 2A As shown, the fibers are uniformly distributed in a network s...

Embodiment 3

[0045] (1) Weigh 0.799 g of EC solid powder with a balance, and dissolve it in 4 mL of hexafluoroisopropanol.

[0046] (2) Add 0.08 g of the ketoprofen drug to the above solution and make it completely dissolved, and stir for 48 hours with a magnetic stirrer until the two are completely dissolved in the solvent and mixed uniformly.

[0047] (3) Put 4mL of the configured spinning solution into the electrospinning device, adjust the spinning parameters for electrospinning, the spray flow rate is 0.4mL / h, the static voltage is 13kV, the receiving distance is 16cm, and the ambient temperature The temperature is 25°C, the humidity is 40-50%, and the spinning time is 7h.

[0048] (4) Put the collected nanomembrane into a vacuum drying oven at 25° C. and dry for 24 hours to obtain an ethylcellulose drug-loaded nanofiber membrane.

[0049] (5) Cut out the 1×1cm fiber membrane and conduct Fourier transform infrared spectroscopy test.

[0050] (6) The FTIR spectra of ketoprofen, ethylcellulose n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com