Novel PDC drill bit with stable function

A drill bit and functional technology, applied in the field of new PDC drill bits with stabilizing functions, can solve problems such as wellbore deviation, compound sheet chipping, poor formation support stability, etc., to ensure the quality of the wellbore, improve the service life, and save drilling cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

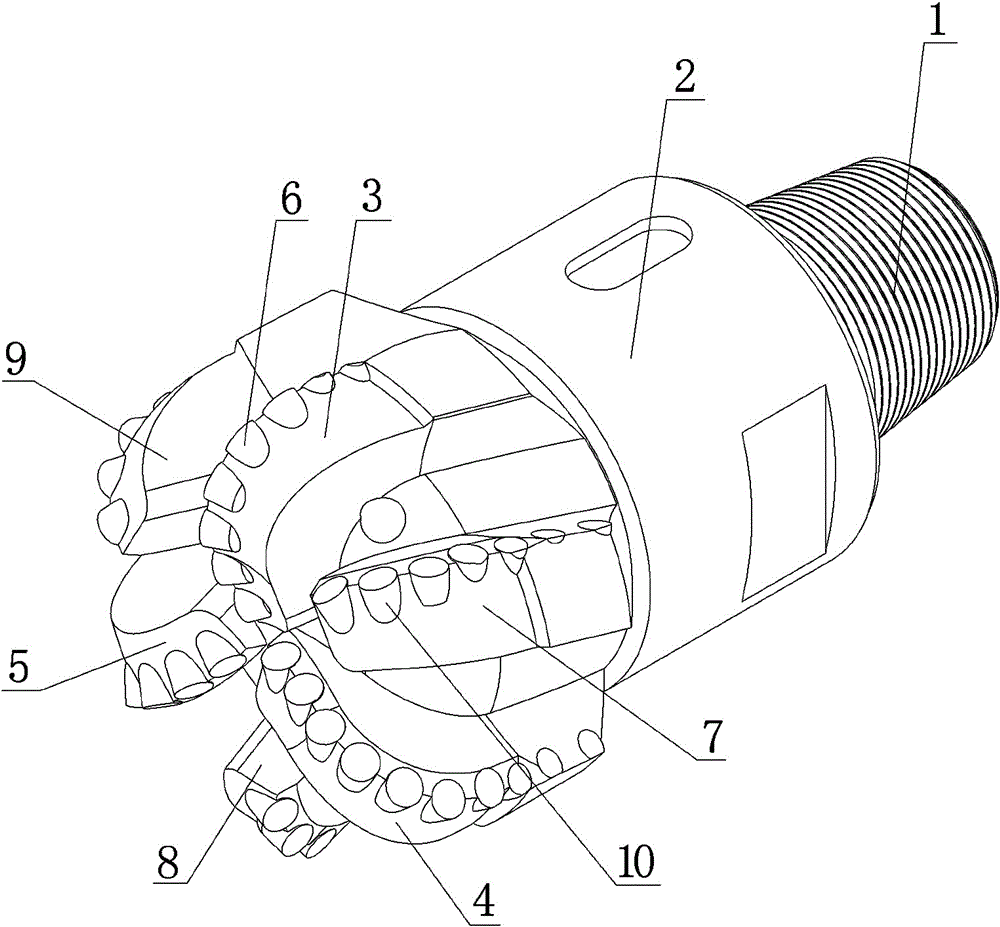

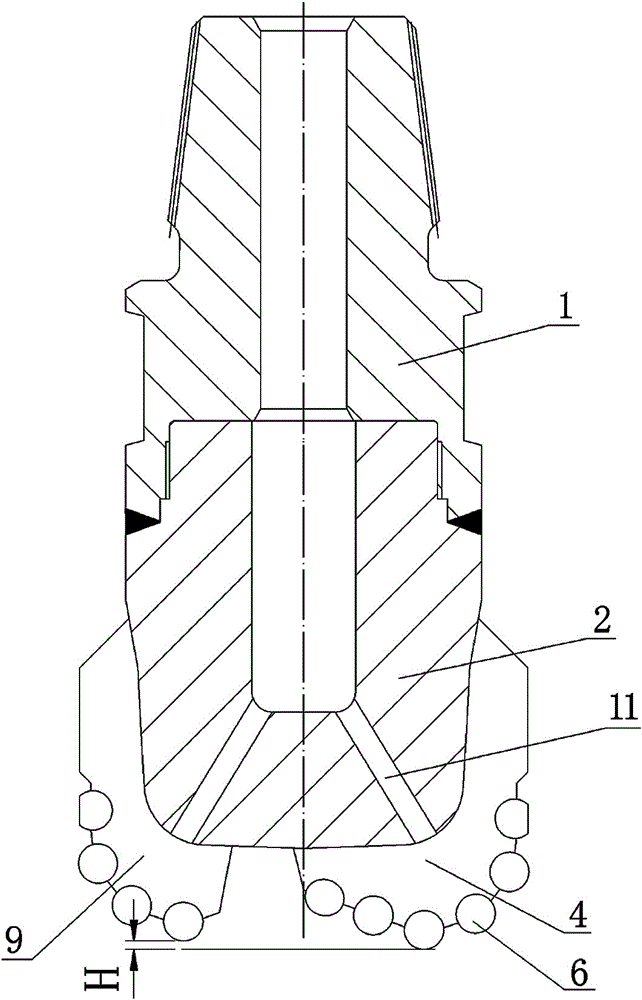

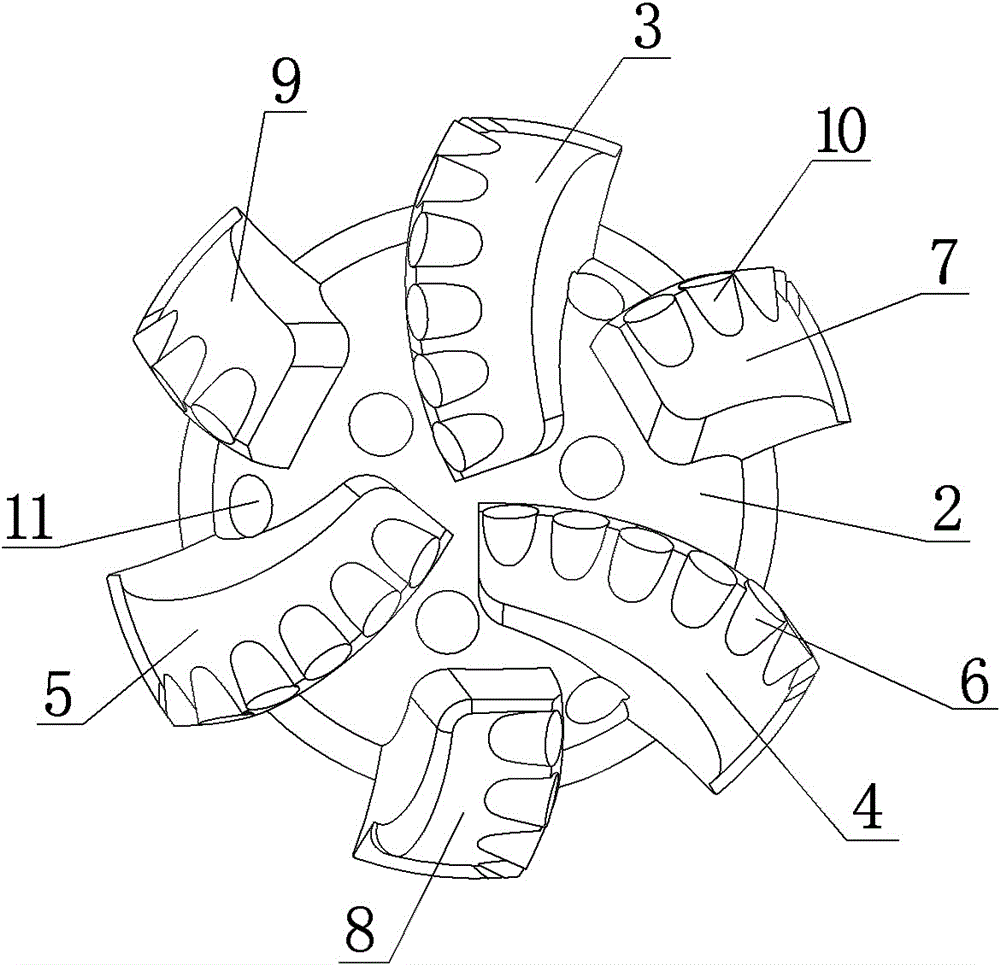

[0013] Such as Figure 1-3 As shown, a new type of PDC drill with stabilizing function includes a drill base 1 and a drill crown 2 arranged on the drill base 1. The drill base 1 adopts a rigid body or a tungsten carbide matrix drill, and the drill base 1 and the drill crown 2 is formed by welding, the drill bit crown 2 is provided with the main blade A3, the main blade B4, the main blade C5, the main blade A3, the main blade B4 and the main blade C5 are evenly distributed, the main blade A3, the main blade B4 The cutting teeth I6 are distributed on the main blade C5, and the cutting teeth I6 on the main blade adopt the conventional method to design the tooth layout, that is, the tooth layout method of the circumferential equidistant helix, and use the equidistant helix distributed with the equal dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com