Machine vision based liquid level sub-quality product marking method

A marking method and qualified product technology, applied in engine lubrication, machines/engines, instruments, etc., to achieve high detection efficiency, high accuracy, and novel detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

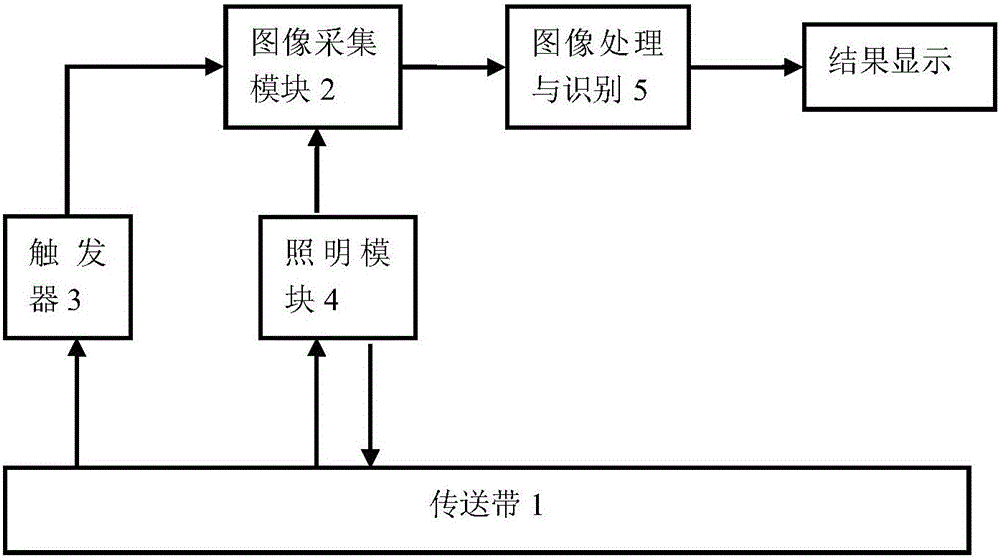

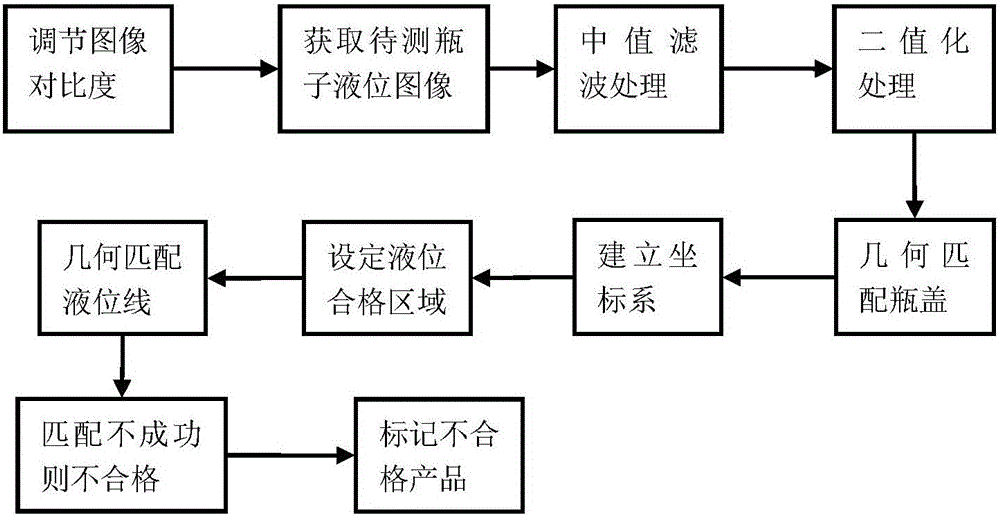

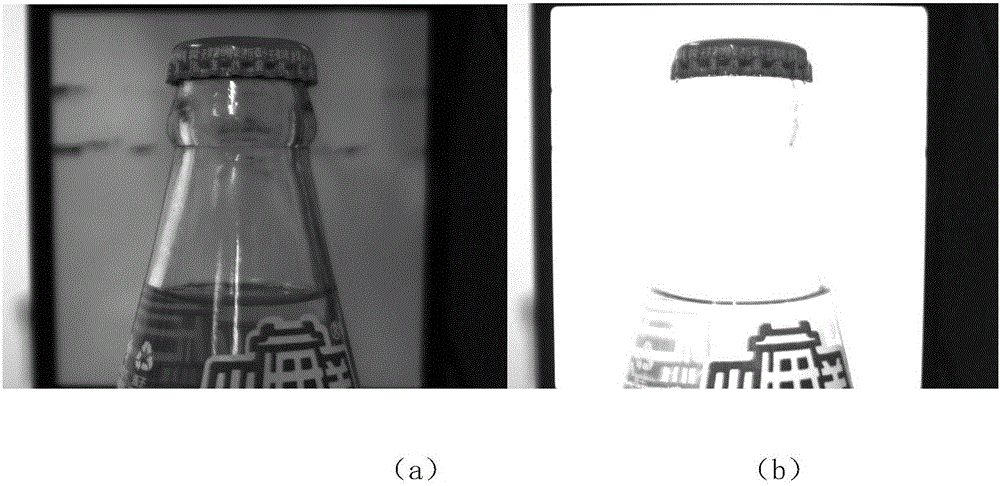

[0024] see figure 1 , a system device for marking unqualified beverage bottle liquid level based on machine vision, which is divided into 6 modules in terms of function, namely conveyor belt 1, image acquisition module 2, photoelectric trigger 3, lighting module 4, image processing and recognition 5 and output control device 6. The above-mentioned image acquisition module 2 uses a 1.2 million-pixel CCD camera, the lighting module 4 uses an LED backlight board, and the image processing and recognition module 5 uses an industrial computer. The output control device consists of a nozzle controlled by a solenoid valve. The conveyor belt 1 transports the bottle to be tested to the photographing station, and the photoelectric trigger device 3 is used to detect whether the bottle arrives at the photographing position, so as to generate a pulse signal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com