Oil and gas production robot comprehensive monitoring system based on Internet of things and cloud computing

A monitoring system and robot technology, applied in general control systems, control/regulation systems, transmission systems, etc., can solve the problems of long maintenance cycle, equipment damage, physical health injury of staff, etc., to ensure safe production, simple structure, A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

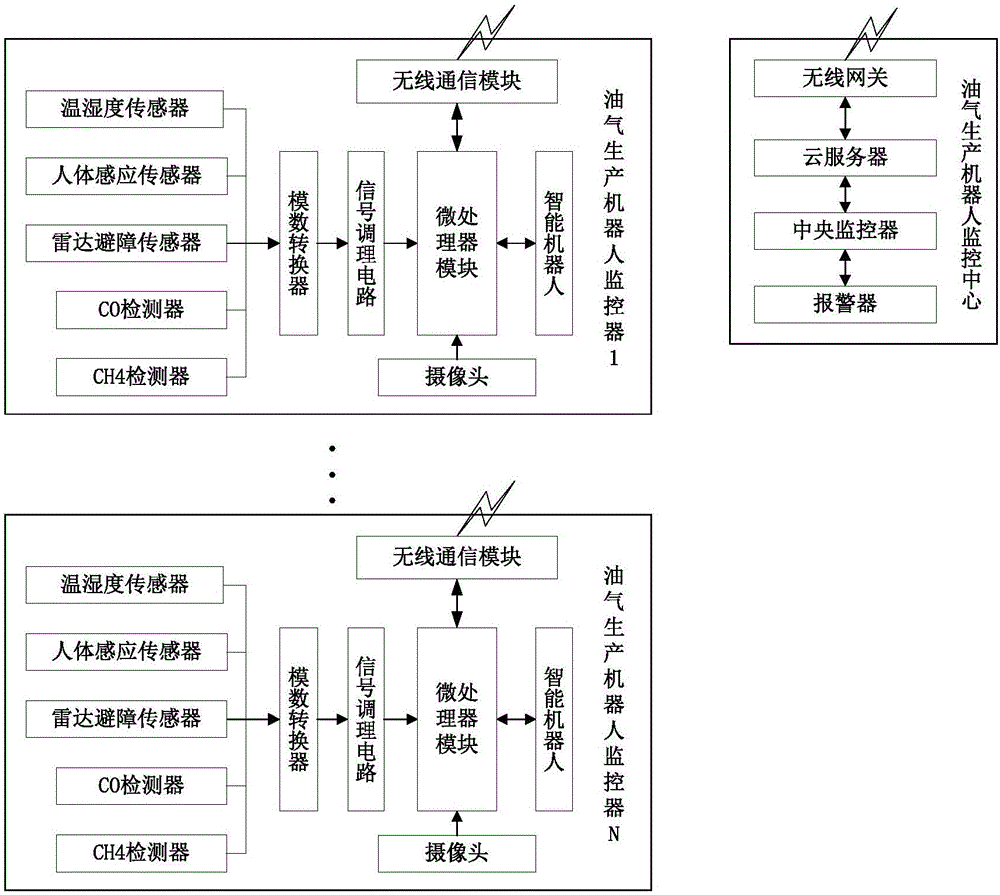

[0013] Such as figure 1 As shown, the omnidirectional monitoring system for oil and gas production robots based on the Internet of Things and cloud computing is composed of multiple oil and gas production robot monitors and an oil and gas production robot monitoring center. The oil and gas production robot monitors include wireless communication modules, micro Processor module, temperature and humidity sensor, human body sensor, radar obstacle avoidance sensor, CO detector, CH 4 Detector, analog-to-digital converter, signal conditioning circuit, camera and intelligent robot; described microprocessor module includes signal input port, microprocessor, memory, power supply interface and signal output port; described oil and gas production robot monitoring center Including wireless gateway, cloud server, central monitor and alarm. Temperature and humidity sensors, human body induction sensors, radar obstacle avoidance sensors, CO detectors, CH 4 The detector is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com