Method for preparing biochar/carbon nano-tubes for cathode materials for sodium ion batteries

A sodium ion battery and carbon nanotube technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of long reaction cycle, difficult control, and high energy consumption in the reaction process, and achieve short reaction time and high heating efficiency. Uniformity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

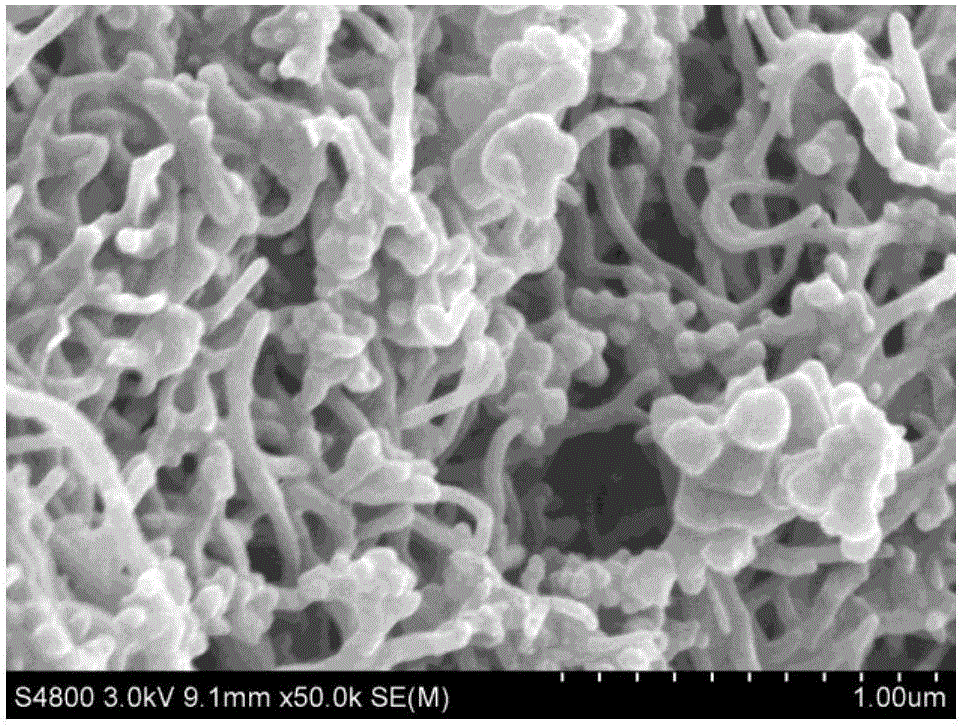

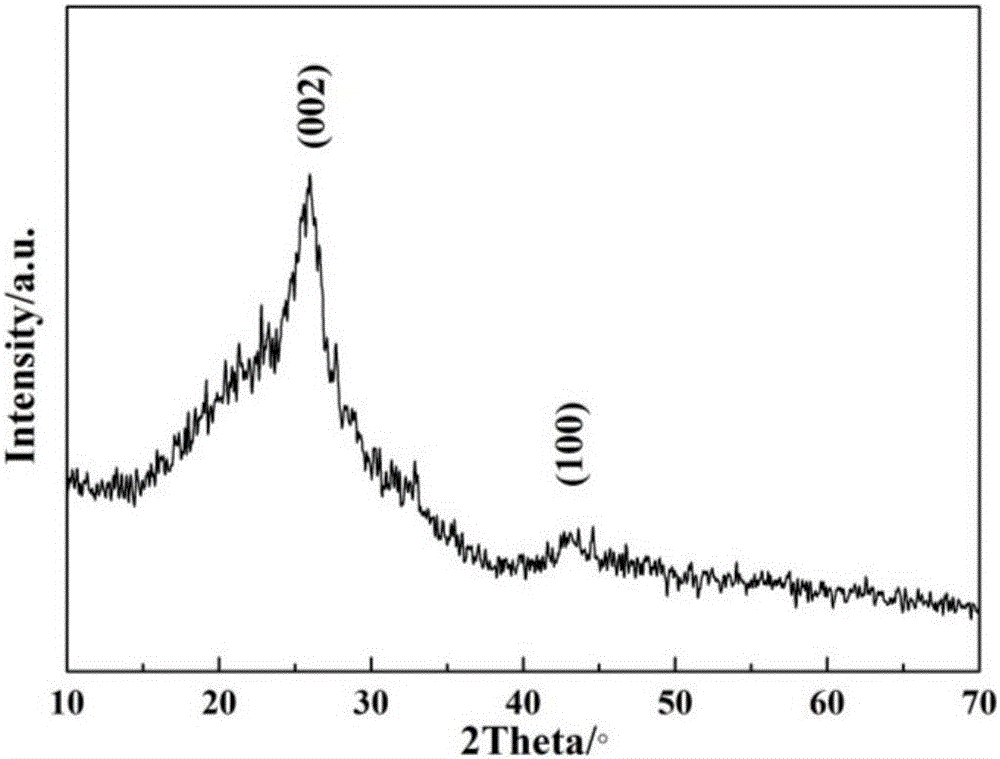

[0028] A preparation method of biological carbon / carbon nanotubes for negative electrode materials of sodium ion batteries, comprising the following steps:

[0029] 1) Wash the pomelo peel to remove surface impurities, and cut it into uniform block A with a diameter of 4-6mm;

[0030] 2) Freeze-drying uniform block A at a temperature of -9°C to -5°C for 12 to 36 hours to obtain block B;

[0031] 3) Add the concentration of 1~5mol·L to block B -1 After adjusting the pH to 1-3 with concentrated sulfuric acid, add carbon nanotubes with a diameter of 50-100 nm and ultrasonically treat them for 12-24 hours, and then put them into the homogeneous equipment and raise the temperature from room temperature to 150 °C at a rate of 6-15 °C / min. ℃~200℃ and keep warm for 12~24h, then naturally cool to room temperature, the temperature is measured by platinum resistance, and the reaction product C is obtained, wherein the mass ratio of block B to carbon nanotube is 5:1~9:1;

[0032] 4) Aft...

Embodiment 1

[0036] (1) Wash the pomelo peel to remove surface impurities, and cut it into pieces A with a diameter of 4 mm;

[0037] (2) Freeze-dry the uniform block A at a temperature of -9°C for 12 hours to obtain block B;

[0038] (3) Add 2mol·L to block B -1 Concentrated sulfuric acid, adjust the pH to 1, and add carbon nanotubes with a diameter of 50nm according to the mass ratio of B: carbon nanotubes of 5:1, ultrasonic for 12h, and then perform a homogeneous reaction, with a heating rate of 6°C / min. The temperature was raised from room temperature to 150°C and kept for 12 hours, and then naturally cooled to room temperature to obtain reaction product C;

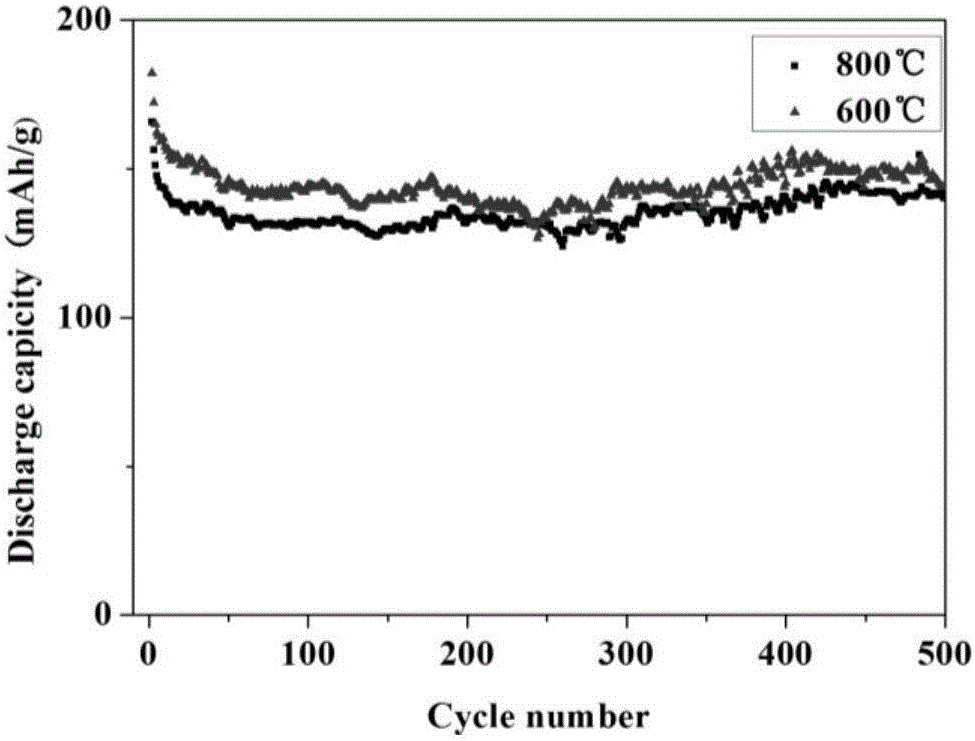

[0039] (4) After the reaction product C was filtered and dried by suction, it was moved into a tubular atmosphere furnace for carbonization with nitrogen gas. The carbonization temperature was raised to 50°C in 10 minutes, and then to 500°C in 75 minutes. ;

[0040] (5) The carbonized product D was first soaked in deionized wat...

Embodiment 2

[0042] (1) Wash the pomelo peel to remove surface impurities, and cut it into pieces A with a diameter of 6 mm;

[0043] (2) Freeze-dry the uniform block A at a temperature of -8°C for 18 hours to obtain block B;

[0044] (3) Add 3mol·L to block B -1 concentrated sulfuric acid, adjust the pH to 2, and add carbon nanotubes with a diameter of 60nm according to the mass ratio of B: carbon nanotubes of 6:1, ultrasonication for 16h, followed by a homogeneous reaction, with a heating rate of 8°C / min. The room temperature was raised to 160°C and kept for 16 hours, and then naturally cooled to room temperature to obtain the reaction product C;

[0045] (4) After the reaction product C was filtered and dried by suction, it was moved into a tubular atmosphere furnace for carbonization with nitrogen gas. The carbonization temperature was raised to 50°C in 10 minutes, and then to 600°C in 75 minutes. It was kept for 2 hours, and then naturally cooled to room temperature to obtain the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com