Method for recycling waste photoresist stripper

A stripper and photoresist technology, which is applied in the field of recycling waste photoresist strippers, can solve problems such as costing a lot of time and money, difficult additives, and reduced process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1 to 20

[0064]

[0065] Fresh stripper liquids having the composition shown in Table 1 below were used in the electronic component manufacturing process. Solids were removed from the resulting spent photoresist stripper using a multi-stage distillation column at a temperature of 150° C. and a pressure of 100 Torr. Thereafter, the lower part of the multistage distillation column was maintained at a temperature of 150°C and a pressure of 100 Torr, and the upper part of the multistage distillation column was maintained at a temperature of 100°C and a pressure of 30 Torr to remove low-boiling point mixtures. Then, the lower portion of the multi-stage distillation column was maintained at a temperature of 150° C. and a pressure of 100 Torr, and the upper portion of the multi-stage distillation column was maintained at a temperature of 130° C. and a pressure of 100 Torr to remove high boiling point mixtures. A purified stripper liquid having the composition shown in Table 2 below was thus...

preparation example 21

[0072]

[0073] A recovered liquid having the composition shown in Table 3 below was prepared.

[0074] 【table 3】

[0075] Composition of recovered liquid

[0076] Imidazolyl-4-ethanol (wt%) 38.5 (2-aminoethoxy)-1-ethanol (wt%) 12.8 Diethylene glycol monobutyl ether (wt%) 42.3 [[(Methyl-1H-benzotriazol-1-yl)methyl]imino]bisethanol (wt%) 3.8 Benzimidazole(wt%) 1.9 Polyether modified siloxane (wt%) 0.7

Embodiment 1 to 20

[0077]

[0078] The purified stripping agent liquid obtained in Preparation Example 1 to Preparation Example 20, the recovery liquid obtained in Preparation Example 21, N-methylformamide, and diethylene glycol monobutyl ether were mixed in the weight ratio shown in Table 4 below. Place in a stirrer and stir at room temperature for 45 minutes to obtain a recovered stripper having the composition shown in Table 5 below.

[0079] 【Table 4】

[0080] Mixing ratio of purified stripping agent liquid, recovery liquid, N-methylformamide and diethylene glycol monobutyl ether

[0081]

[0082] 【table 5】

[0083] Composition of recycled stripper

[0084]

[0085] *IME: imidazolyl-4-ethanol

[0086] *AEE: (2-Amino-ethoxy)-1-ethanol

[0087] *NMF: N-methylformamide

[0088] *BDG: Diethylene glycol monobutyl ether

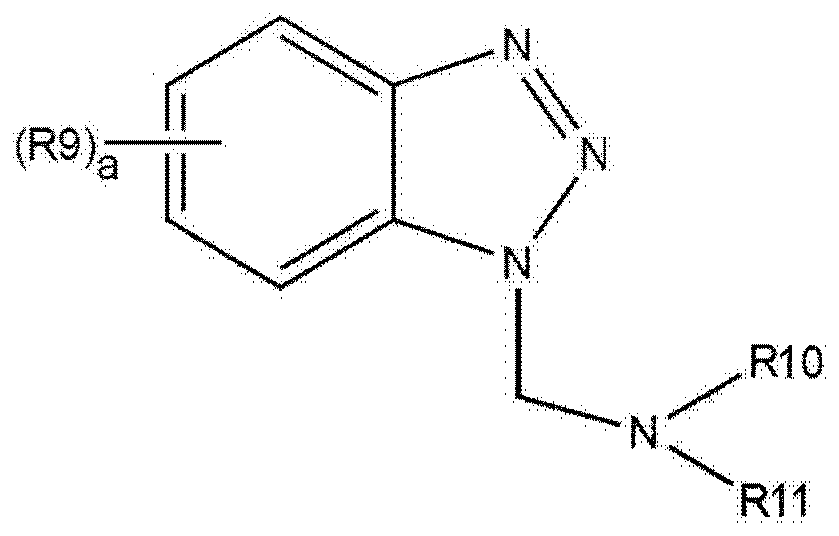

[0089] *First corrosion inhibitor: [[(methyl-1-benzotriazol-1-yl)methyl]imino]bisethanol

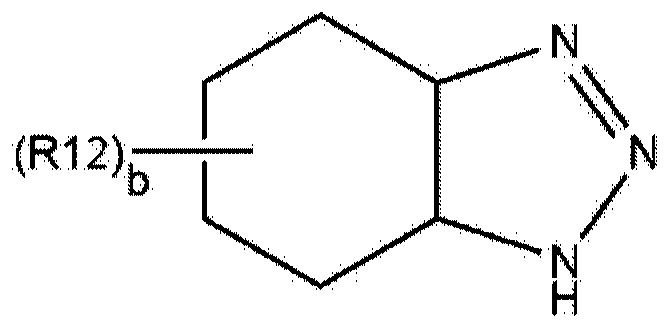

[0090] *Second corrosion inhibitor: benzimidazole

[0091] *Surfactant:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com