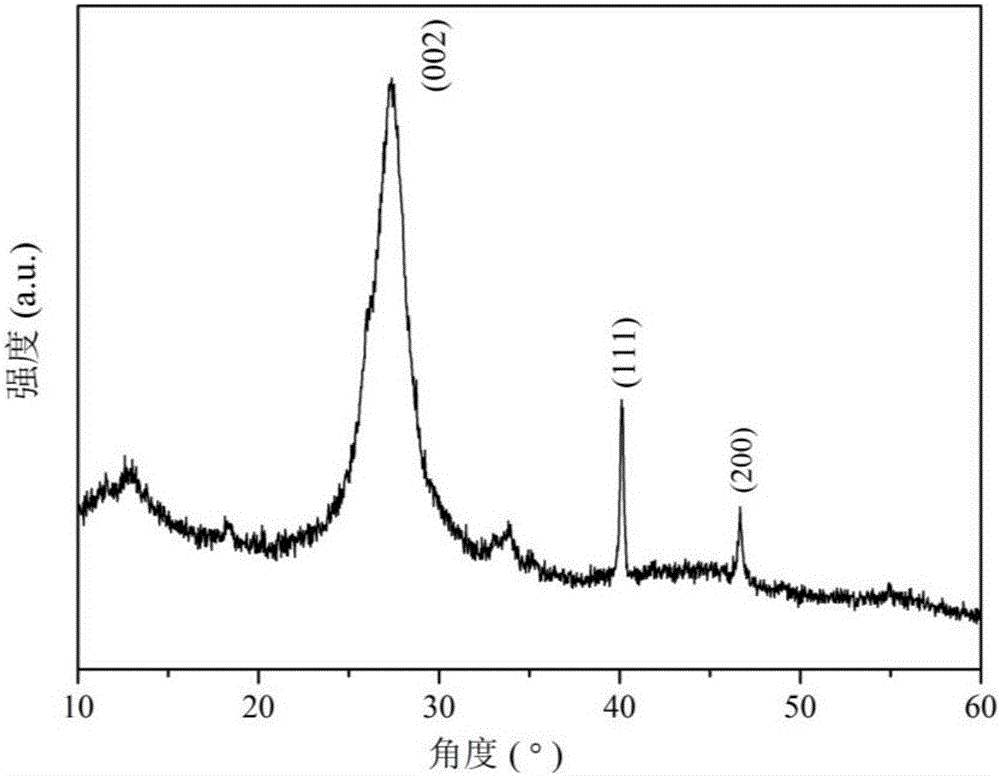

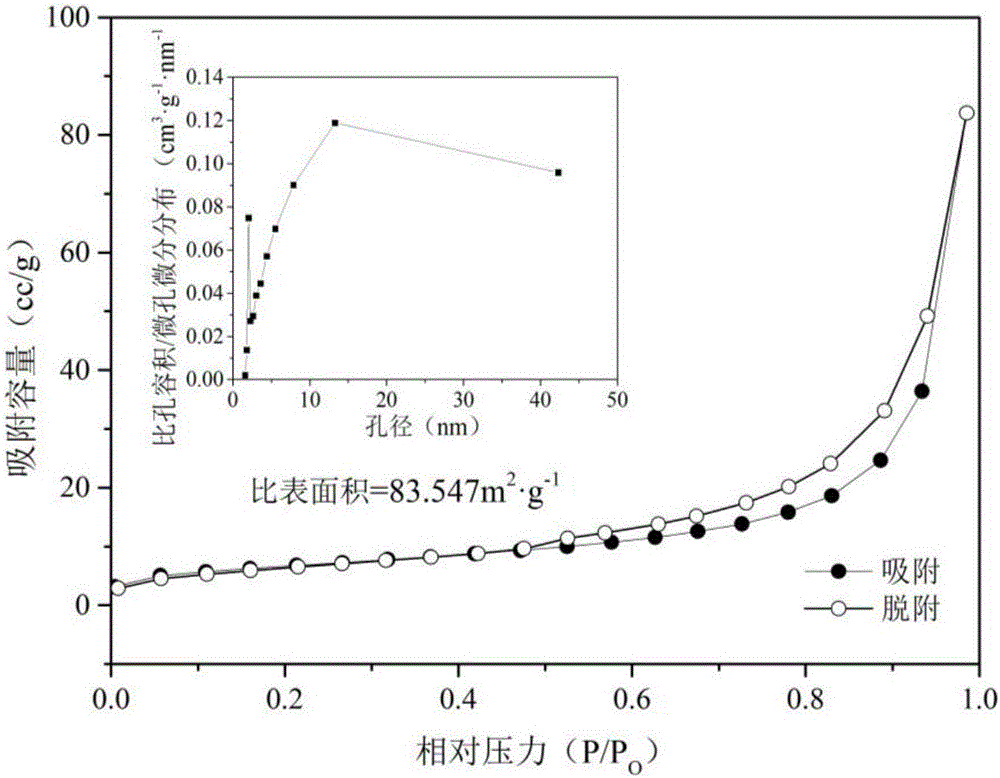

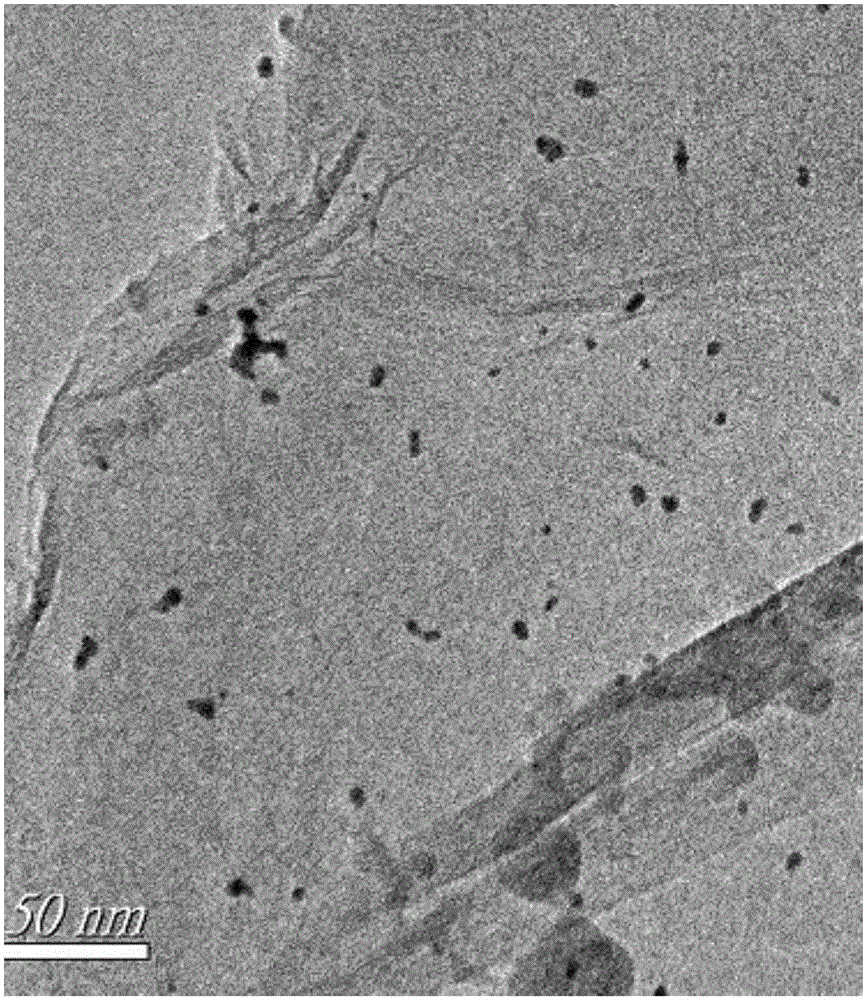

Mesoporous graphite carbon nitride/palladium composite material, preparation method and application thereof

A composite material and carbon nitride-like technology, which is applied in the field of material science to achieve the effects of low cost, few steps and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A mesoporous g-C 3 N 4 / Pd composite preparation method, the steps are as follows:

[0027]First, 10g of melamine powder was calcined at 600°C for 2 hours, and after cooling down to room temperature, 2g of yellow block g-C was obtained. 3 N 4 .

[0028] Put 2g of yellow block g-C 3 N 4 After being ground into powder, it was added to 100 mL of concentrated sulfuric acid and stirred for 12 hours, then slowly added with 1 g of sodium nitrate and 4 g of potassium permanganate, and stirred at room temperature for 5 hours. The mixed solution was then diluted into 300 mL of deionized water and 67 mL of hydrogen peroxide was added. Finally, it was dialyzed to neutral and collected by centrifugation to obtain white g-C 3 N 4 .

[0029] will collect the white g-C 3 N 4 Add to 1L methanol / water (V / V=1 / 1) solution, ultrasonic treatment for 10 hours; then disperse the system in 3000min -1 Centrifuge for 10 minutes to remove undispersed precipitates, and dry in vacuum at ...

Embodiment 2

[0032] A mesoporous g-C 3 N 4 / Pd composite preparation method, the steps are as follows:

[0033] First, 20g of melamine powder was calcined at 600°C for 2 hours, and after cooling down to room temperature, 4.5g of yellow blocky g-C was obtained. 3 N 4 .

[0034] 4.5g of yellow block g-C 3 N 4 After being ground into powder, it was added to 225mL of concentrated sulfuric acid and stirred for 15 hours, then slowly added 3g of sodium nitrate and 12g of potassium permanganate, and stirred at room temperature for 8 hours. The mixed solution was then diluted into 675 mL of deionized water and 150 mL of hydrogen peroxide was added. Finally, it was dialyzed to neutral and collected by centrifugation to obtain white g-C 3 N 4 .

[0035] will collect the white g-C 3 N 4 Add to 2.25L ethanol / water (V / V=2 / 1) solution, ultrasonic treatment for 15 hours; then disperse the system in 3000min -1 Centrifuge for 10 minutes to remove undispersed precipitates, and dry in vacuum at 40...

Embodiment 3

[0038] A mesoporous g-C 3 N 4 / Pd composite preparation method, the steps are as follows:

[0039] First, 30g of melamine powder was calcined at 600°C for 2 hours, and after cooling down to room temperature, 7g of yellow block g-C was obtained. 3 N 4 .

[0040] 7g of yellow block g-C 3 N 4 After being ground into powder, it was added to 350mL of concentrated sulfuric acid and stirred for 24 hours, then slowly added 7g of sodium nitrate and 35g of potassium permanganate, and stirred at room temperature for 10 hours. The mixed solution was then diluted into 1050 mL of deionized water and 233 mL of hydrogen peroxide was added. Finally, it is dialyzed to neutrality and collected by centrifugation.

[0041] will collect the white g-C 3 N 4 Add to 3.5L isopropanol / water (V / V=3 / 1) solution, ultrasonic treatment for 20 hours; -1 Centrifuge for 10 min to remove the undispersed precipitate, and dry in vacuum at 40°C for 12 h to obtain 6.5 g of off-white solid powder, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com