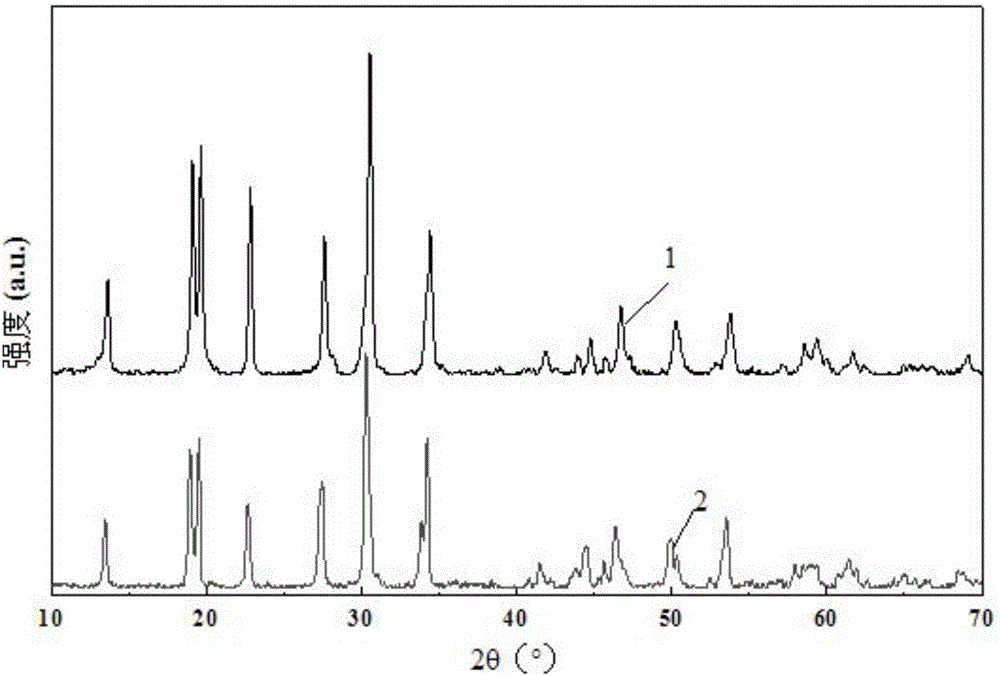

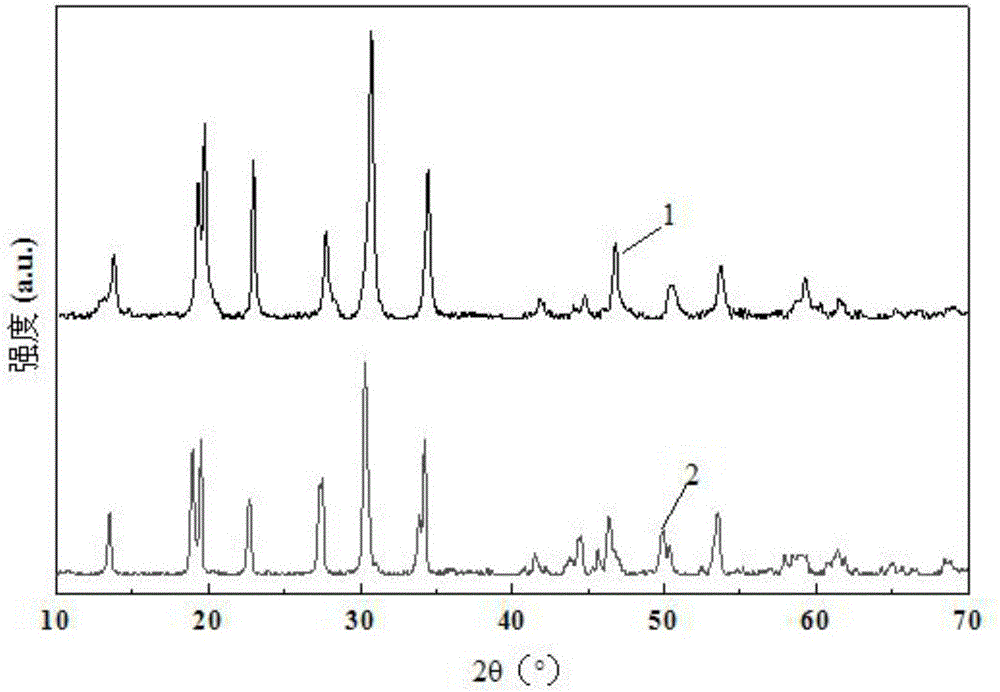

Preparation method of Na3+2xZr2-xMxSi2PO12 solid electrolyte powder material

A solid electrolyte and powder material technology, applied in electrolytes, circuits, electrical components, etc., can solve the problems of powder agglomeration, low conductivity, high reaction temperature, etc., and achieve lower sintering temperature, high reactivity, and lower reaction temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

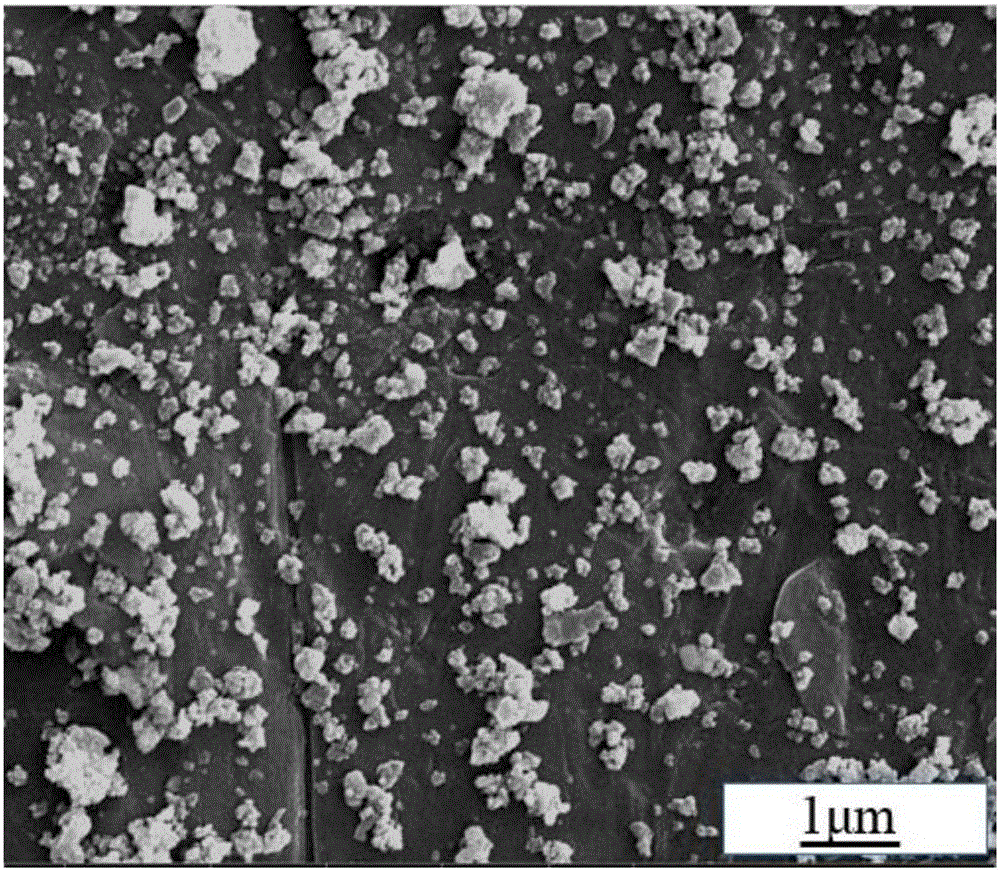

[0025] Specific embodiment one: a kind of Na of this embodiment 3+2x Zr 2–x m x Si 2 PO 12 The preparation method of solid electrolyte powder material is carried out according to the following steps:

[0026] 1. NaNO 3 , ZrO(NO 3 ) 2 2H 2 O, M (NO 3 ) 2 ·nH 2 O and (NH 4 ) 2 HPO 4 Dissolve in deionized water respectively to obtain NaNO with a concentration of 1.5mol / L~6mol / L 3 Solution, ZrO(NO 3 ) 2 Solution, M(NO 3 ) 2 Solution and concentration of 0.25mol / L~1mol / L (NH 4 ) 2 HPO 4 solution; the M(NO 3 ) 2 ·nH 2 M=Co in O 2+ 、Ni 2+ , Zn 2+ or Mg 2+ ;

[0027] 2. Add deionized water and dispersant to absolute ethanol, stir until the dispersant is completely dissolved to obtain a dispersant solution, then add TEOS to the dispersant solution, use a magnetic stirrer at a speed of 15r / min to 25r / min Stir under the condition of mixing until uniform, then drop the catalyst to adjust the pH to 0.5-3.5, and then hydrolyze for 1h-5h at a temperature of 40-60...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the dispersant in step 2 is citric acid, PEG1000 or CTAB. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the catalyst described in step 2 is concentrated nitric acid, oxalic acid or acetic acid. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com