Modeling feed for constructing hyperhomocysteinemia animal model and preparation method thereof

A technology of cysteinemia and animal models, which is applied in the field of building animal models for medical experiments, can solve the problems of animal phenotype changes, unfavorable clarification of experimental results, changes, etc., to achieve increased methionine content, simple production process, and easy modeling good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

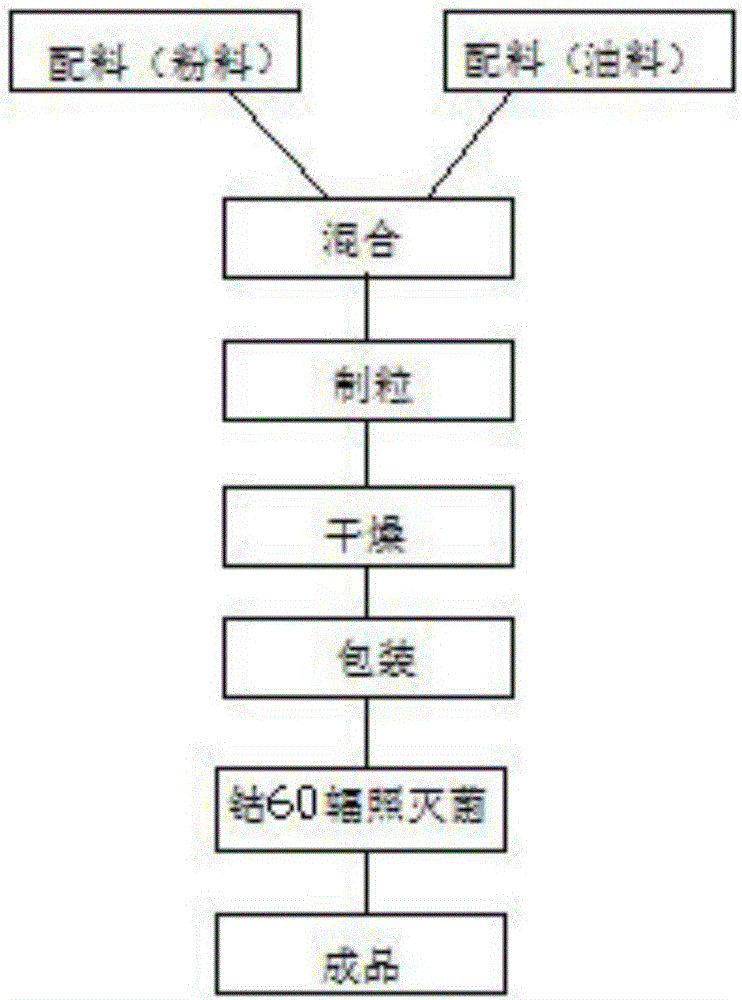

[0047] The preparation method includes the following steps:

[0048] 1), raw material pretreatment,

[0049] Weigh casein, corn starch, sucrose, cellulose, DL-methionine, L-cystine, complex minerals, complex vitamins and dihydrocholine citrate in proportion;

[0050] Weigh 6%-10% of the vegetable oil, add water to the vegetable oil, the amount of water added is 2-9% of the total weight of the raw materials, and continue to stir evenly to form a semi-liquid fat;

[0051] 2), prepare the mixture,

[0052] Mix the weighed raw materials, stir evenly, for 1 to 2 minutes, then gradually add the above semi-liquid fat, continue to stir and mix for 3 to 5 minutes;

[0053] 3) Prepare products,

[0054] At 15~30℃, evenly add the above-mentioned mixed materials to the ring die pelletizer, extrude the materials from the ring die aperture through the ring die pelletizer rollers to form the semi-finished feed, and then transfer the semi-finished feed through the blade Cut into feed pellets with a diam...

specific Embodiment 1

[0057] 1), raw material pretreatment,

[0058] Proportionally weigh 20% casein, 40% corn starch, 10% sucrose, 3% cellulose, 1% DL-methionine, 0.1% L-cystine, 2% complex minerals, 0.5% complex vitamins and citric acid Dihydrocholine 0.1%, weigh 6% vegetable oil, add 2% water to the vegetable oil, stir it evenly, and present a semi-liquid fat;

[0059] 2), prepare the mixture,

[0060] Mix the weighed raw materials, stir evenly, for 1 to 2 minutes, then gradually add the above semi-liquid fat, continue to stir and mix for 3 to 5 minutes;

[0061] 3) Prepare products,

[0062] At 15~30℃, evenly add the above-mentioned mixed materials to the ring die pelletizer, extrude the materials from the ring die aperture through the ring die pelletizer rollers to form the semi-finished feed, and then transfer the semi-finished feed through the blade Cut into feed pellets with a diameter of 10-12mm and a length of 15-20mm. Pass the feed pellets through a dehumidifier at a temperature of 18-25°C and t...

specific Embodiment 2

[0065] 1), raw material pretreatment,

[0066] Weigh 30% casein, 50% corn starch, 20% sucrose, 9% cellulose, 3% DL-methionine, 1% L-cystine, 5% complex minerals, 3% complex vitamins and citric acid according to the proportions. Dihydrocholine 1%, weigh 10% of vegetable oil, add 9% of water to the vegetable oil, stir evenly, and become a semi-liquid fat;

[0067] 2), prepare the mixture,

[0068] Mix the weighed raw materials and stir them evenly for 2 minutes, then gradually add the above semi-liquid fats and continue mixing for 3 minutes;

[0069] 2), prepare the mixture,

[0070] Mix the weighed raw materials, stir evenly, for 1 to 2 minutes, then gradually add the above semi-liquid fat, continue to stir and mix for 3 to 5 minutes;

[0071] 3) Prepare products,

[0072] At 15~30℃, evenly add the above-mentioned mixed materials to the ring die pelletizer, extrude the materials from the ring die aperture through the ring die pelletizer rollers to form the semi-finished feed, and then tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com