Double-nerve-factor connected polypyrrole-polylactic acid parallel conductive porous composite filament membrane and preparing thereof

A nerve factor, composite silk technology, applied in filament/thread forming, medical science, non-woven fabrics, etc., to achieve the effect of simple and easy method, improved biocompatibility and nerve repair, and large number of connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

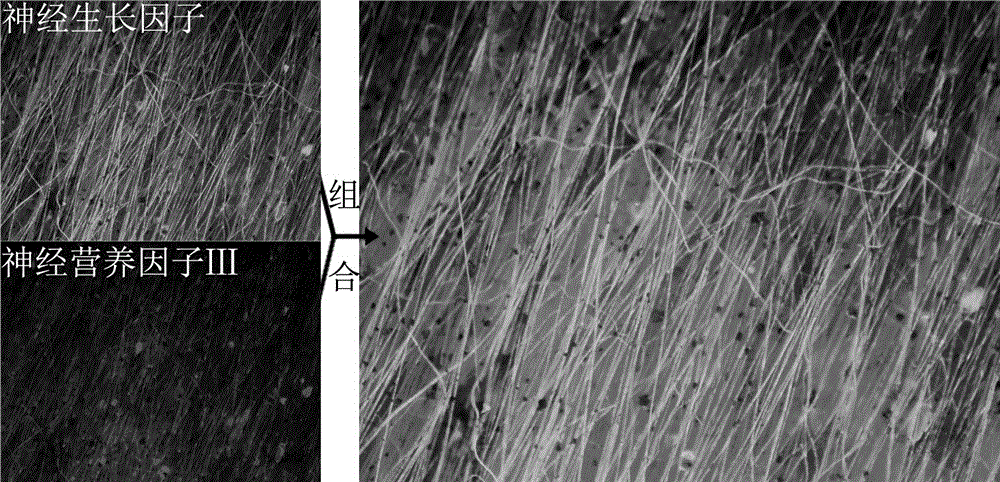

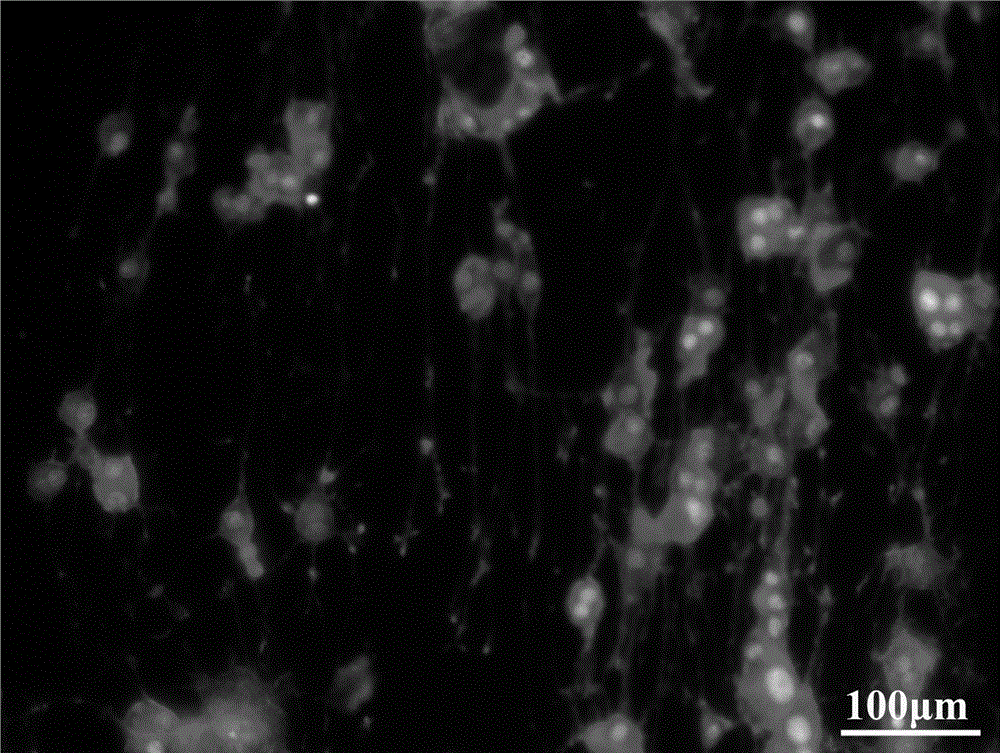

[0019] Dissolve 0.3 g of polylactic acid with a viscosity of ~2.3dL in 3.6 mL of dichloromethane, then add 0.4 mL of N,N dimethylformamide into the dissolved polylactic acid solution, sonicate for 15 minutes and continue magnetic stirring for 12 hours Make it fully miscible. Put the dissolved polylactic acid solution into the syringe pump, set the pump speed to 0.5-2.0 mL / h, the spinning voltage to 10-15 kV, the spinning distance to 8-25 cm, and the diameter of the collecting drum to be 12 cm. cm, the drum speed is 400-2000 r / min, and the electrospinning time is 3 hours, the parallel porous polylactic acid nanofilament membrane can be obtained. Prepare a mixed solution containing DBS and polyglutamic acid at a concentration of 14 mM and 14 mM, respectively, and then add 100 mL of pyrrole monomer under magnetic stirring, continue to stir and ultrasonically form a suspension, and immerse the silk film in the C pre-cooled pyrrole solution for 0.5 hours, and then slowly added dro...

Embodiment 2

[0021]Mix 3.6 mL of dichloromethane and 0.4 mL of N, N dimethylformamide evenly, then dissolve 0.3 g of polylactic acid with a viscosity of ~2.3dL in the mixture, ultrasonicate for half an hour and stir for 12 hours, then add the solution to For the syringe pump, set the corresponding parameters: pump propulsion rate is 0.5 ~ 2.0 mL / h, voltage is 10 ~ 15kV, spinning distance is controlled at 8 ~ 25 cm, collection drum diameter is 12 cm, drum speed is 400 ~ 2000 r / min, electrospinning for 3 hours. The silk film was soaked in solutions containing DBS, polyglutamic acid and pyrrole monomer concentrations of 14 mM, 28 mM and 100 mL respectively, and kept the mixed microemulsion and ferric chloride solution at 4 °C in precooling , the ferric chloride solution was added dropwise into the microemulsion and shaken for 12 hours. Activate the conductive filament membrane with a mixed solution with a pH of 5.0, EDC and NHS concentrations of 0.2 M and 0.05 M, respectively, for 0.5 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com