Preparation method of cellulose and fibroin composite small-caliber artificial blood vessel material

A technology of artificial blood vessels and cellulose, applied in the fields of medical formula, medical science, prosthesis, etc., can solve the problems of easy formation of thrombus, strong hydrophobicity, poor tissue compatibility, etc., and achieve the effect of expanding the range of raw materials and overcoming poor compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

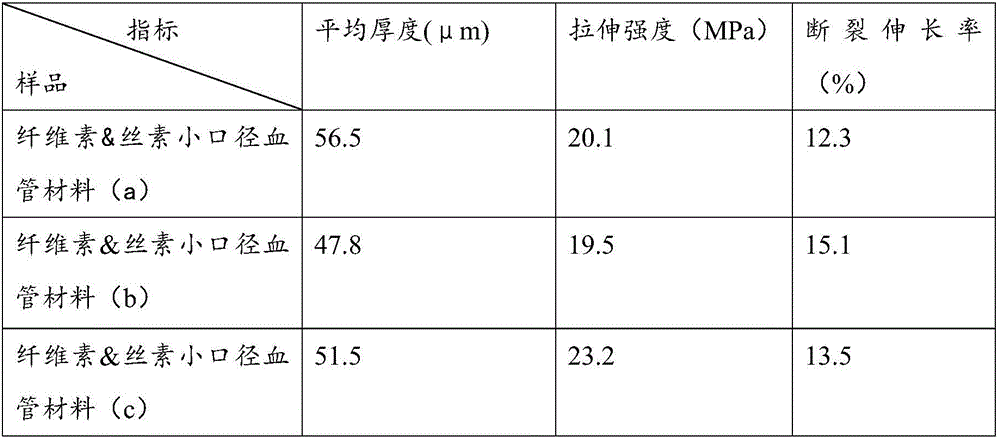

Embodiment 1

[0026] 1) After the bamboo pulp is dried, it is pulverized by a plant pulverizer and filtered through a 180-mesh screen to obtain the bamboo pulp powder with a particle size of 0.08 mm.

[0027] 2) Put the moso bamboo pulp powder obtained in step 1) under the action of mechanical stirring, and place it in a 1wt% cellulase solution at 60°C to react for 360 minutes. The mass ratio of the moso bamboo pulp powder to the cellulase solution is 1:1. 10 times the volume of the above-mentioned cellulase solution in distilled water to terminate the reaction, then centrifuged to wash away the residual enzyme, and at room temperature, the reacted mixture was packed into a dialysis bag with a molecular weight cut-off of 120k Da, and dialyzed in distilled water until the dialysis was Neutral solution, freeze-dried to obtain nano-microcrystalline cellulose.

[0028] 3) Dissolving the nano-microcrystalline cellulose obtained in step 2) in sodium hydroxide / urea solution, the mass fraction rati...

Embodiment 2

[0032] 1) After the bamboo pulp is dried, it is pulverized by a plant pulverizer and filtered through a 180-mesh screen to obtain the bamboo pulp powder with a particle size of 0.07 mm.

[0033] 2) Put the moso bamboo pulp powder obtained in step 1) under the action of mechanical stirring, and place it in 0.5wt% cellulase solution at 50°C to react for 450min, the mass ratio of moso bamboo pulp powder to cellulase solution is 1:1, Use room temperature distilled water 10 times the volume of the above-mentioned cellulase solution to terminate the reaction, then centrifuge to wash away the residual enzyme, and put the reacted mixture into a dialysis bag with a molecular weight cut-off of 120kDa at room temperature, and dialyze in distilled water until the dialysis It is a neutral solution and freeze-dried to obtain nanocrystalline cellulose.

[0034] 3) Dissolving the nano-microcrystalline cellulose obtained in step 2) in sodium hydroxide / urea solution, the mass fraction ratio of so...

Embodiment 3

[0038] 1) After the bamboo pulp is dried, it is pulverized by a plant pulverizer and filtered through a 180-mesh screen to obtain the bamboo pulp powder with a particle size of 0.06 mm.

[0039] 2) Put the moso bamboo pulp powder obtained in step 1) under the action of mechanical stirring, and place it in a 2wt% cellulase solution at 70°C to react for 270min. The mass ratio of the moso bamboo pulp powder to the cellulase solution is 1:2. Terminate the reaction with distilled water at room temperature 10 times the volume of the above enzyme solution, then centrifuge to wash away the residual enzyme, and put the reacted mixture into a dialysis bag with a molecular weight cut-off of 120k Da at room temperature, and dialyze in distilled water until the dialysis becomes neutral solution, freeze-dried to obtain nanocrystalline cellulose.

[0040] 3) Dissolving the nano-microcrystalline cellulose obtained in step 2) in sodium hydroxide / urea solution, the mass fraction ratio of sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com