Micelle modified nanometer zero-valent iron particle and preparation method and application thereof

A nano-zero-valent iron, modification and modification technology, applied in the field of preparation and modification of nano-materials, can solve the problems of increased application cost, secondary environmental pollution, etc., and achieves easy operation, good biocompatibility, and good dispersion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

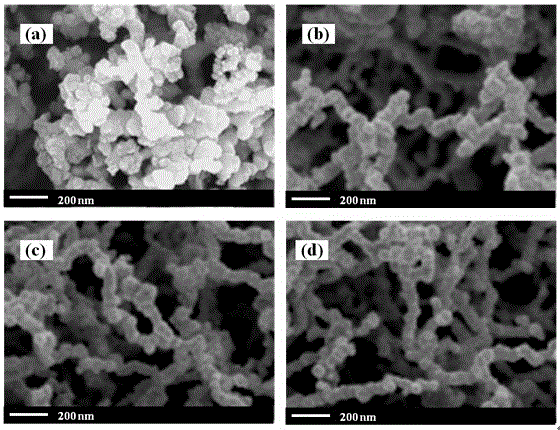

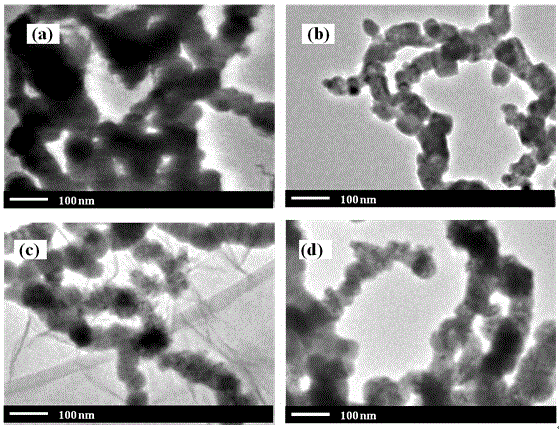

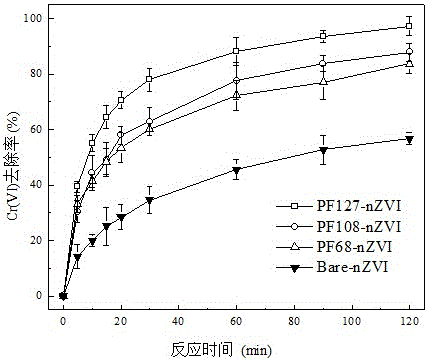

[0037] Preparation of three kinds of poloxamers (Poloxamer F68, Poloxamer F108 and Poloxamer F127) modified nano-zero-valent iron and the removal of Cr(VI)

[0038] A poloxamer modified nano zero valent iron, the modified nano zero valent iron includes nano zero valent iron and poloxamers (poloxamer F68, poloxamer F108 and poloxamer F127), poloxamer Sham self-assembled to form micelles coated on the surface of nano-zero-valent iron, and poloxamer micelles modify the surface of nano-zero-valent iron; the concentration of poloxamer in the modified nano-zero-valent iron is 5mmol / L The temperature of the solution is controlled at 30°C when poloxamer is added during the preparation of the nano-zero-valent iron.

[0039] (1) FeSO 4 Solution preparation: weigh 20g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve and transfer to a 100mL volumetric flask, dilute to the mark, shake well, then 0.7M FeSO can be obtained 4 Solution.

[0040] (2) KBH 4 Solu...

Embodiment 2

[0050] Preparation of Poloxamer F127 Modified Nano-Zerovalent Iron and Removal of Orange II Dye

[0051] A poloxamer modified nano zero valent iron, the modified nano zero valent iron includes nano zero valent iron and poloxamer F127, poloxamer F127 self-assembles to form micelles coated on the surface of the nano zero valent iron, Poloxamer F127 micelles are used to modify the surface of nano-zero-valent iron; the concentration of poloxamer F127 in the modified nano-zero-valent iron is 0.5 mmol / L; the poloxam is added during the preparation of the nano-zero-valent iron When F127 is used, the temperature of the solution is controlled at 25°C.

[0052] (1) FeSO 4 Solution preparation: weigh 14.3g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve and transfer to a 100mL volumetric flask, dilute to the mark, shake well, you can get 0.5mol / L FeSO 4 Solution.

[0053] (2) NaBH 4 Solution preparation: Weigh 5.67g into a beaker, add an appropriate amo...

Embodiment 3

[0058] Preparation of Poloxamer F127 Modified Nano-Zerovalent Iron and Removal of Metronidazole

[0059] A poloxamer modified nano-zero-valent iron, the modified nano-zero-valent iron includes nano-zero-valent iron and poloxamer F127, the poloxamer F127 self-assembles to form micelles coated on the surface of the nano-zero-valent iron, Poloxamer F127 micelles are used to modify the surface of nano-zero-valent iron; the concentration of poloxamer F127 in the modified nano-zero-valent iron is 8mmol / L; the poloxamer is added during the preparation of the nano-zero-valent iron For F127, the temperature of the solution is controlled at 40°C.

[0060] (1) FeSO 4 Solution preparation: weigh 25.7g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve and transfer to a 100mL volumetric flask, dilute to the mark, and shake well to obtain 0.9mol / L FeSO 4 Solution.

[0061] (2) KBH 4 Solution preparation: Weigh 7.7g into a beaker, add an appropriate amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com