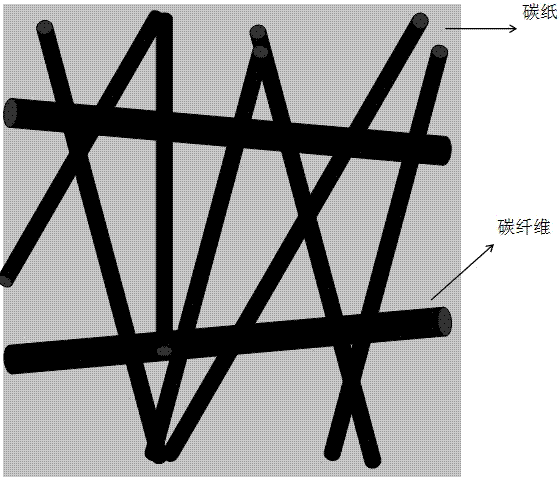

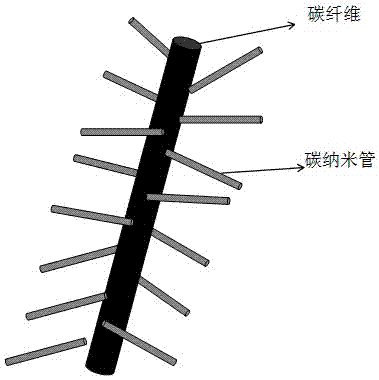

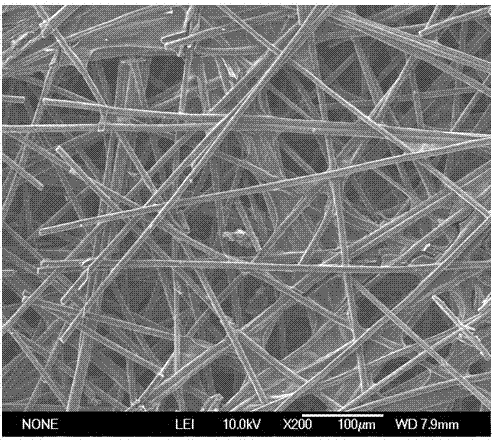

Preparation method of pine needle-like carbon nanotube/carbon fiber conductive network composite carbon material

A carbon nanotube and conductive network technology, which is applied in the field of preparation of carbon nanotube/carbon fiber composite carbon materials, can solve the problems of harsh control conditions, difficult to carry out, and less growth of carbon nanotubes, and achieves high specific surface area and improves stability. , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Pretreatment of carbon fiber fabric

[0038] First, the carbon fiber fabric is ultrasonically cleaned in isopropanol for 20 minutes and dried at 80°C for 20 minutes; secondly, the sizing agent on the carbon fiber surface is thermally decomposed and calcined in a tube furnace for 6 hours at a temperature of 600°C; then, Carry out acid treatment on the surface of the carbon fiber fabric, soak in concentrated nitric acid for 3 hours, and dry at 60°C for 4 hours to obtain a carbon fiber fabric with clean surface; then, weigh 6.06g ferric nitrate and 0.2g sucrose and dissolve in 15g silica sol and 2ml In the solvent of ethanol, magnetically stirred at room temperature for 12 hours to prepare the inorganic metal catalyst precursor solution; finally, the carbon fiber fabric with clean surface was soaked in the inorganic metal catalyst precursor solution for 60 minutes, filtered for 2 minutes and dried at 80°C for 5 hours . This process is repeated twice to make the ferric ni...

Embodiment 2

[0044] (1) Pretreatment of carbon fiber fabric

[0045] First, the carbon fiber fabric is ultrasonically cleaned in ethanol solution for 40 minutes and dried at 60°C for 20 minutes; secondly, the sizing agent on the carbon fiber surface is thermally decomposed and calcined in a muffle furnace for 7 hours at a temperature of 400°C; The surface of the carbon fiber fabric is acid treated, soaked in concentrated sulfuric acid for 6 hours, and dried at 60°C for 4 hours to obtain a clean carbon fiber fabric; then, weigh 8.08g cobalt nitrate and 0.27g glucose and dissolve in 20g silica sol and 4ml isopropyl In an alcohol solvent, magnetically stirred at room temperature for 12 hours to prepare the inorganic metal catalyst precursor solution; finally, the carbon fiber fabric with clean surface was soaked in the inorganic metal catalyst precursor solution for 60 minutes, filtered for 2 minutes and dried at 80°C for 5 hours . This process is repeated 4 times, so that cobalt nitrate and gl...

Embodiment 3

[0051] (1) Pretreatment of carbon fiber fabric

[0052] First, the carbon fiber fabric is ultrasonically cleaned in ethanol solution for 30 minutes and dried at 80°C for 20 minutes; secondly, the sizing agent on the carbon fiber surface is thermally decomposed and calcined in a muffle furnace for 6 hours at a temperature of 400°C; The surface of the carbon fiber fabric is acid treated, soaked in a solution of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 1:1 for 3 hours, and dried at 60°C for 4 hours to obtain a carbon fiber fabric with clean surface; then, weigh 16.16g of nickel nitrate Dissolve 0.27g maltodextrin in a solvent of 20g silica sol and 4ml isopropanol, stir magnetically for 18 hours at room temperature, and configure the inorganic metal catalyst precursor solution; finally, soak the carbon fiber fabric with clean surface in the inorganic metal catalyst precursor Leave the solution in the solution for 30 minutes, filter with suction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com