A composite cement curing agent used for filling with waste slag obtained after subjecting gold ore tailings to iron separation

A technology for gold mine tailings and curing agent, which is applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of difficult tailings transportation, large amount of curing agent, and low strength of the cured body. , to achieve the effect of resource utilization, low production cost and small volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

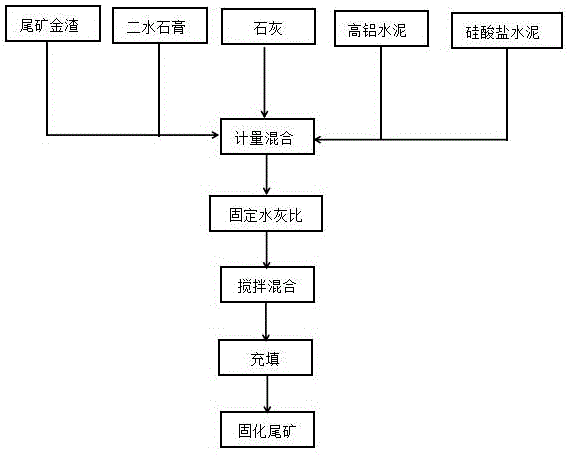

Method used

Image

Examples

Embodiment 1

[0027] 1. The mass fraction of the three composite curing agents is 15%, and the ratio of the composite curing agents is as follows: Ordinary Portland cement (P.O 52.5): 70%; Slaked lime: 20%; High alumina cement (CA600): 10 %. The dry mass fraction of gold slag is 85%, and the water-cement ratio in this experiment is 0.535;

[0028] 2. According to the above ratio, mix 85g of gold tailings gold slag and 15g of composite curing agent together with a mixer, then add a fixed quality of water into the mixture, stir with a cement slurry mixer for 4 minutes, and then mix Pour the processed mixture into a mold for molding, and finally put the molded sample into the air for curing for 1 day to obtain the solidified gold slag product;

[0029]3. After the gold slag is solidified, the unconfined compressive strength reaches 1.01MPa at 1d, 3.24MPa at 3d, 4.63MPa at 7d, and 4.63MPa at 28d. It is 4.87MPa, and the mechanical properties of the cured product basically tend to be stable.

Embodiment 2

[0031] 1. The mass fraction of the three composite curing agents is 15%, and the ratio of the composite curing agents is as follows: Ordinary Portland cement (P.O 52.5): 10%, Slaked lime: 20%, High alumina cement (CA600): 70 %, the mass fraction of gold slag dry basis is 85%, and the water-cement ratio in this experiment is 0.535;

[0032] 2. According to the above ratio, mix 85g of gold tailings and gold slag and 15g of composite curing agent together with a mixer, then add a fixed quality of water into the mixture, stir with a cement slurry mixer for 4 minutes, and then mix The stirred mixture is poured into a mold for molding, and finally the molded sample is placed in the air for 1 day of curing to obtain the cured product;

[0033] 3. After the gold slag is solidified, the unconfined compressive strength reaches 1.24MPa at 1d, 1.66MPa at 3d, 2.09MPa at 7d, and 28d at 28d It is 1.75MPa, and the strength of 28d solidified gold slag produces slight shrinkage.

Embodiment 3

[0035] 1. The mass fraction of the three composite curing agents is 15%, and the ratio of the composite curing agents is as follows: Ordinary Portland cement (P.O 52.5): 75%; Dihydrate gypsum: 10%; High alumina cement (CA600) : 15%. The dry mass fraction of gold slag is 85%, and the water-cement ratio in this experiment is 0.535;

[0036] 2. According to the above ratio, mix 85g of gold tailings gold slag and 15g of composite curing agent together with a mixer, then add a fixed quality of water into the mixture, stir with a cement slurry mixer for 4 minutes, and then mix The processed mixture is poured into a mold for molding, and finally the molded sample is placed in the air for 1 day of curing to obtain the cured product;

[0037] 3. After the gold slag is solidified, the unconfined compressive strength reaches 1.18MPa at 1d, 2.78MPa at 3d, 3.89MPa at 7d, and 3.89MPa at 28d. It is 2.90MPa. At the same time, the mechanical properties of the cured product tend to be stable,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com