Bonded novel energy accumulation luminescence long-acting pavement marking tape

A technology of energy-storage luminescence and marking tape, applied in the field of transportation, can solve problems such as poor visibility for drivers, hidden dangers in safety, time-consuming and labor-intensive cleaning, etc., to achieve superior energy storage and continuous luminescence, production Low cost and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1. Preparation of a new type of white sticky energy-storage luminescent long-lasting marking tape:

[0016] 1) Preparation of base material: take alkali-free glass fiber woven cloth with a thickness of 0.5-2.0mm, and make it into a fabric with a width of 5-30cm and a length of 5-200m, which is resistant to high temperature, corrosion, less moisture absorption and high tensile strength strip substrate.

[0017] 2) Preparation of polyester resin varnish: Take polyester resin and isocyanate at a weight ratio of 10:1 to prepare a polyester resin with high adhesion, good wear resistance, high film-forming hardness, good flexibility and good weather resistance varnish.

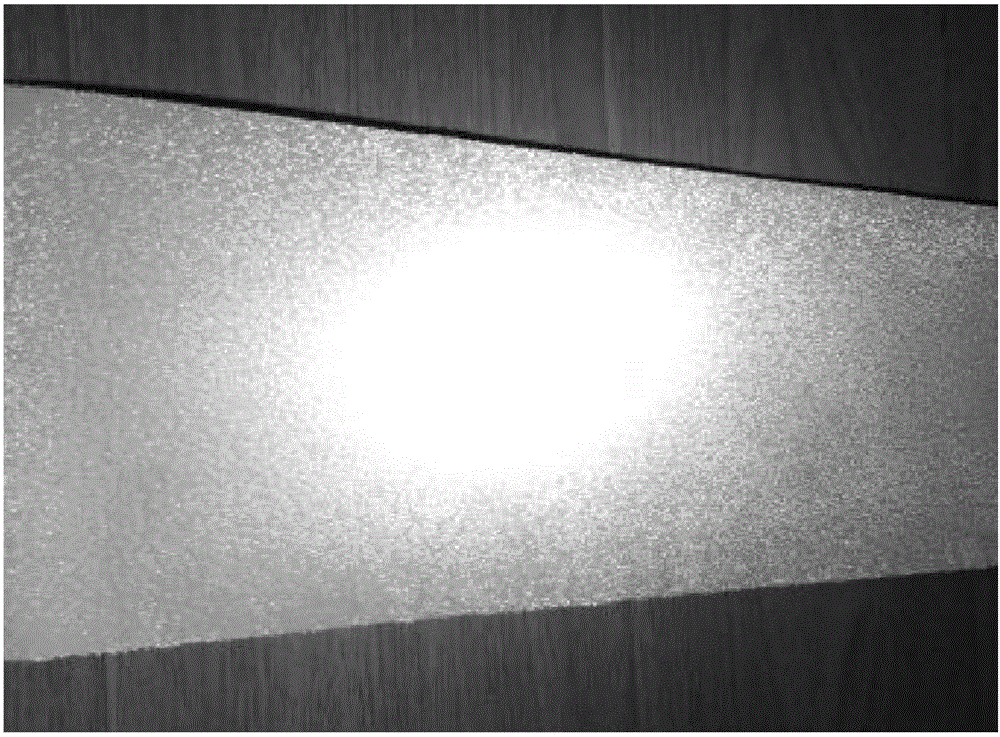

[0018] 3) Preparation of substrate surface coating: Add 25kg of 200-mesh yellow-green energy-storage luminescent powder to the above-mentioned 35kg polyester resin varnish, 15kg of titanium dioxide, 20kg of glass beads with a reflectivity of 1.5 and a particle size of 30 mesh, and 5kg of corundum. ...

Embodiment 2

[0021] Example 2. Preparation of a new type of yellow sticky energy-storage luminescent long-lasting marking tape:

[0022] 1) Preparation of base material: Take an alkali-free glass fiber woven cloth (referred to as alkali-free glass fiber cloth) with a thickness of 0.5-2.0 mm, and make a high-temperature-resistant, corrosion-resistant, Tape substrate with low moisture absorption and high tensile strength.

[0023] 2) Preparation of epoxy resin varnish: Take epoxy resin and curing agent according to the weight ratio of 4:1 to prepare epoxy resin with high adhesion, good wear resistance, high film forming hardness, good flexibility and good weather resistance. Resin varnish.

[0024] 3) Preparation of substrate surface coating: Add 35kg of 200-mesh blue-green energy storage luminescent powder, 0.2kg of chrome yellow, reflectivity of 1.9, 30-mesh glass beads 25k and quartz to the above-mentioned 30kg of epoxy resin varnish 10kg of sand was stirred and dispersed on a high-spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com