Method for separating ferrum and vanadium in vanadium pickle liquor

A technology of soaking solution and vanadic acid, which is applied in the field of separating iron and vanadium in vanadic acid soaking solution, can solve the problems of poor separation effect of iron and vanadium, and achieve the effects of small consumption of chemicals, efficient separation and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for separating iron and vanadium in vanadic acid leaching solution, its concrete steps are:

[0024] Add Na to the vanadic acid immersion solution 2 SO 3 , stirred, and carried out a reduction reaction at 75°C for 20 minutes to obtain a reduced solution;

[0025] Add milk of lime to adjust the pH of the reduced solution to 1.7 to obtain the adjusted emulsion; then separate the solid and liquid of the adjusted emulsion to obtain the original solution and the pH-adjusted slag;

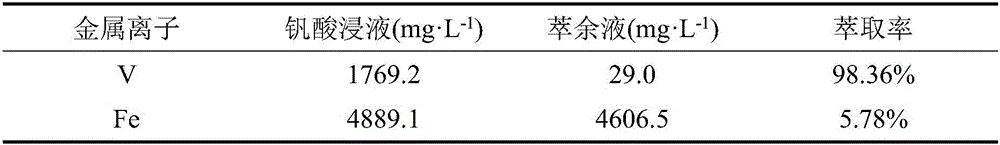

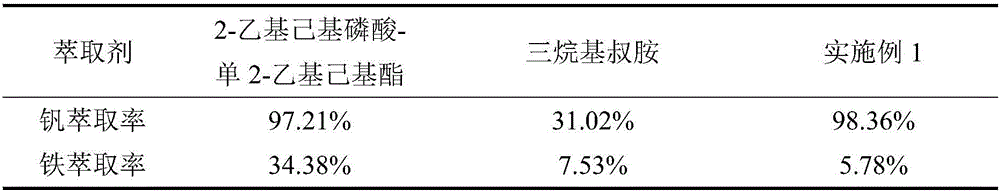

[0026] 15% 2-ethylhexyl phosphoric acid-mono-2-ethylhexyl ester, 35% trialkyl tertiary amine and 50% sulfonated kerosene by volume are mixed with the extraction stock solution at a volume ratio of 0.2:1, and stirred After 3 minutes, the mixed phase was obtained; the mixed phase was separated after standing, and after 4 stages of extraction, the vanadium-loaded organic phase and the iron-containing raffinate were obtained. The ion concentrations of vanadic acid soaking solution and raff...

Embodiment 2

[0035] A method for separating iron and vanadium in vanadic acid leaching solution, its concrete steps are:

[0036] Add Na to the vanadic acid immersion solution 2 SO 3 , stirred, and carried out a reduction reaction at 30°C for 120 minutes to obtain a reduced solution;

[0037] Adding ammonia water to adjust the pH of the reduced solution to 2.5 to obtain the adjusted emulsion; then separating the solid and liquid of the adjusted emulsion to obtain the original solution and the pH-adjusted slag;

[0038] The mixed extractant prepared by volume ratio of 30% bis(2-ethylhexyl) phosphate, 5% secondary carbon primary amine and 65% sulfonated kerosene is mixed with the extraction stock solution by volume ratio of 1:1, and stirred for 15min to obtain the mixed phase ; After the mixed phase is left to stand, the phases are separated, and after a first-stage extraction, a vanadium-loaded organic phase and an iron-containing raffinate are obtained. The ion concentrations of vanadic...

Embodiment 3

[0043] A method for separating iron and vanadium in vanadic acid leaching solution, its concrete steps are:

[0044] Add Na to the vanadic acid immersion solution 2 SO 3 , stirred, and carried out a reduction reaction at 60°C for 70 minutes to obtain a reduced solution;

[0045] Add NaOH solution to adjust the pH of the reduced solution to 1.0 to obtain the adjusted emulsion; then separate the solid and liquid of the adjusted emulsion to obtain the original solution and the pH-adjusted slag;

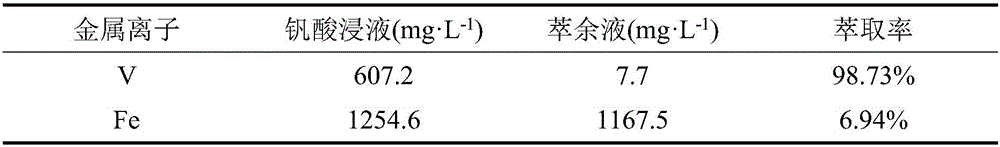

[0046] The mixed extraction agent prepared by volume ratio of 10% bis(2-ethylhexyl) phosphate, 10% trialkyl tertiary amine and 80% sulfonated kerosene is mixed with the extraction stock solution by volume ratio of 0.5:1, stirred for 8 minutes, and mixed phase; after the mixed phase is left to stand, the phases are separated, and after five stages of extraction, the vanadium-loaded organic phase and the iron-containing raffinate are obtained. The ion concentrations of vanadic acid soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com