A method for recovering lead and silver from lead sulfate slag

A technology of lead sulfate and metallic lead, which is applied in the field of lead and silver recovery, can solve the problems of low crystal quality, narrow use of lead chloride, and harsh operating conditions, and achieve the effects of fast replacement rate, easy operation, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

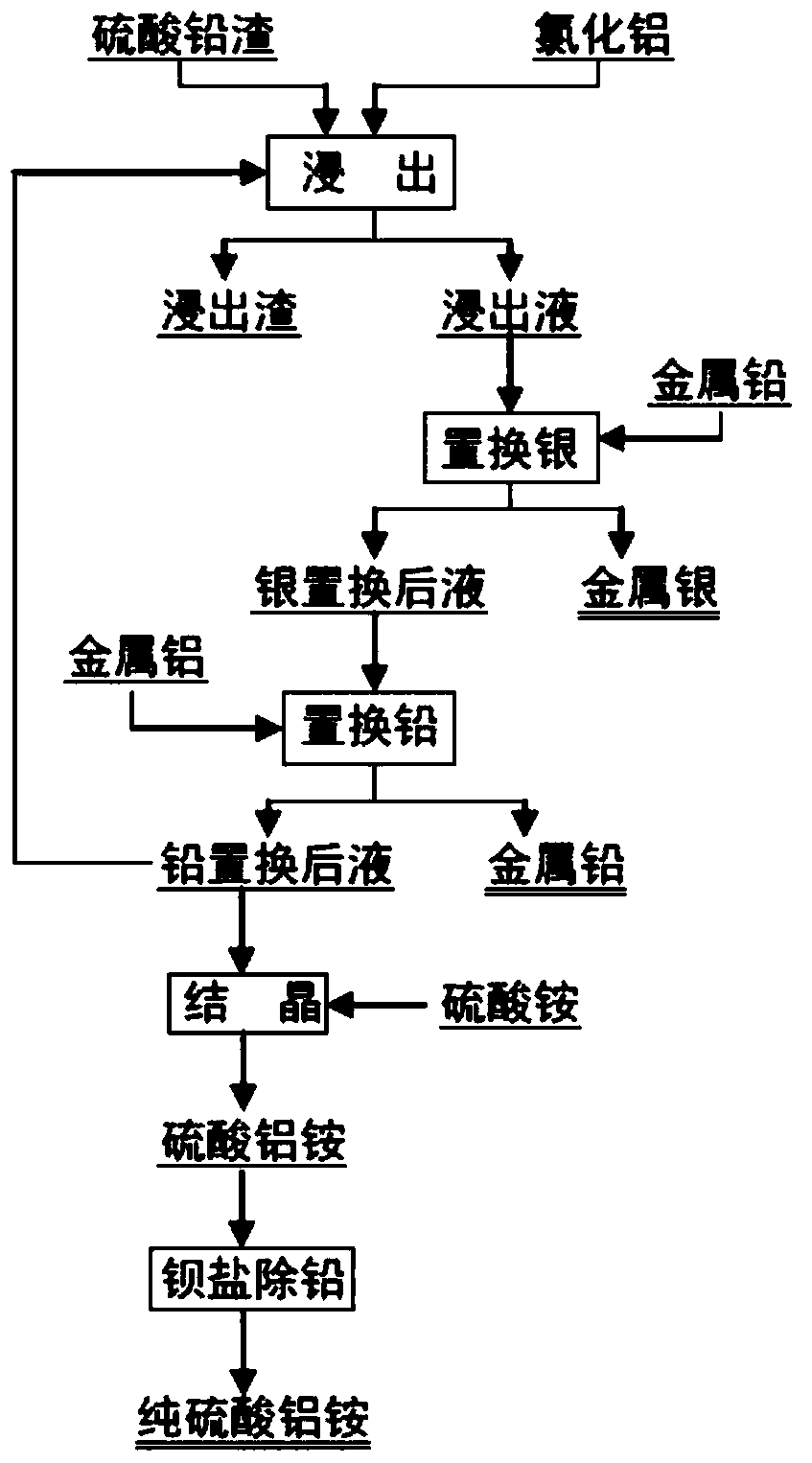

Method used

Image

Examples

Embodiment 1

[0025] Leaching: 1kg zinc leaching residue (Pb 17.5%, Ag 700g / t), leaching agent is 350g / L aluminum chloride solution, leaching temperature is 90°C, leaching time is 2h, pH of the leaching process is 0.5, liquid-solid ratio is 7.1:1. Lead leaching rate reaches 93%, silver leaching rate reaches 94%.

[0026] Silver replacement: use lead plate as the replacement agent, the replacement temperature is 30°C, the amount of metal lead is 1 times the theoretical amount, and the replacement is 4 hours to obtain 0.68g of coarse silver powder with a silver content of 91.3%.

[0027] Replacement of lead: use aluminum plate as the replacement agent, the replacement temperature is 30°C, the amount of aluminum plate is 1 times the theoretical amount, and the replacement is 1 hour to obtain a total of 164g of fine lead sludge with a lead content of 97.5%.

[0028] Aluminum ammonium sulfate crystallization: at room temperature at 25°C, add 500g / L (NH 4 ) 2 SO 4 Solution, form ammonium alumi...

Embodiment 2

[0031] Leaching: 1kg zinc leaching residue (Pb 32.6%, Ag 750g / t), leaching agent is 350g / L aluminum chloride solution, leaching temperature is 90°C, leaching time is 2h, pH of the leaching process is 1.0, liquid-solid ratio is 16.3:1. Lead leaching rate reaches 93.5%, silver leaching rate reaches 93%.

[0032] Silver replacement: use lead plate as the replacement agent, the replacement temperature is 30°C, the amount of metal lead is 1 times the theoretical amount, and the replacement is 4 hours to obtain 0.76g of coarse silver powder with a silver content of 90.1%.

[0033] Replacement of lead: use aluminum plate as the replacement agent, the replacement temperature is 30°C, the amount of aluminum plate is 1 times the theoretical amount, and the replacement is 1h to obtain a total of 304g of fine lead sludge with a lead content of 98.2%.

[0034] Aluminum ammonium sulfate crystallization: at room temperature at 25°C, add 500g / L (NH 4 ) 2 SO 4 Solution, form ammonium alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com